Technical article

2023-07-20

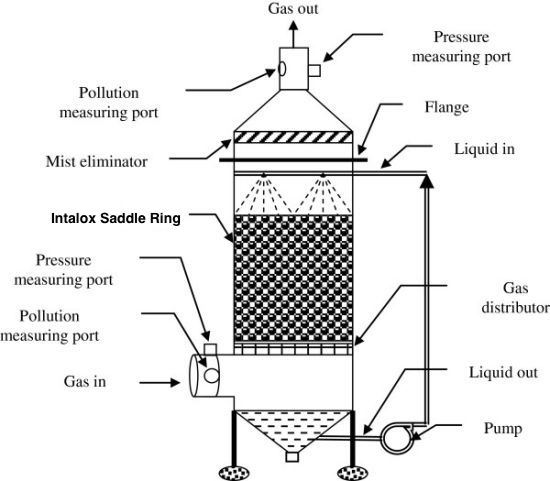

In tower applications, the choice of packing material plays a crucial role in optimizing process efficiency and achieving desired results. One such highly effective and versatile packing solution is the metal Intalox saddle ring. With its unique design and numerous advantages, this packing material has gained significant popularity in various industrial processes. In this article, we will delve into the details of metal Intalox saddle rings and explore their diverse applications in towers.

What are Metal Intalox Saddle Rings?

Metal Intalox saddle rings are structured packing elements used in towers for mass transfer operations, such as absorption, distillation, and stripping. They are typically made from metals like stainless steel or carbon steel and have a distinctive shape resembling a saddle with smooth internal and external surfaces. The rings are stacked within tower columns to create a high surface area for efficient liquid-gas contact.

What’s the advantages of Metal Intalox Saddle Rings?

1st. High Efficiency: The unique saddle shape of the rings ensures excellent gas-liquid mixing, resulting in enhanced mass transfer efficiency.

2nd. Superior Liquid Distribution: Metal Intalox saddle rings promote uniform liquid distribution over the packing bed, preventing channeling and promoting maximum contact between phases.

3rd. Enhanced Capacity: The large free-flow area and optimum geometry of the rings facilitate higher liquid and vapor handling capacities, increasing tower performance.

4th. Reduced Pressure Drop: The open structure of the saddle rings minimizes pressure drop, allowing for increased throughput and energy savings.

5th. Mechanical Strength: Metal Intalox saddle rings exhibit excellent mechanical strength and can withstand high liquid and gas loads in demanding tower applications.

6th. Corrosion Resistance: With options for stainless steel construction, these rings offer exceptional corrosion resistance, making them suitable for corrosive environments.