Technical article

2025-10-16

High alumina balls are used as heat storage balls for regenerative gas furnaces, mainly as support medai in the heat storage chamber, to improve combustion efficiency and achieve energy conservation in universities through dual preheating of combustion supporting air.

With the increasing global demand for energy conservation and emission reduction, regenerative combustion technology has been widely applied in the high-temperature smelting industry. As the core carrier of this technology, the performance of thermal storage fillers directly determines the efficiency and lifespan of the system. This article aims to explore in depth the advantages, working principles, key technical parameters, and comprehensive application value of high alumina balls as high-quality thermal storage fillers in modern smelters.

One: Energy Challenges and Thermal Storage Technologies in the Smelting Industry

The refinery industry is a typical high energy consuming industry, and the large amount of high-temperature flue gas (usually above 1000 ℃) generated by its furnace equipment during operation carries about 30% -70% of the input energy. In traditional craftsmanship, this part of the heat is often directly discharged, causing huge energy waste and thermal pollution.

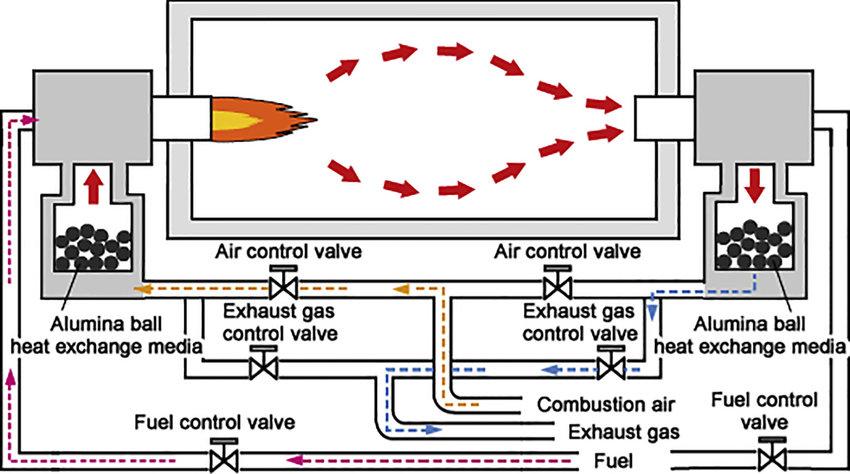

The regenerative combustion system cleverly solves this problem through its core component - the regenerative chamber. The system uses paired heat storage chambers to alternate between "heat storage" and "heat release" cycles, thereby maximizing the recovery of waste heat from flue gas and using it to preheat combustion air or gas, ultimately achieving near maximum heat recovery efficiency (up to 90% or more). In this cycle, the performance of the thermal storage filler filled in the thermal storage chamber is crucial, and high alumina balls are currently one of the most widely used and comprehensive performance optimal choices.

Two: The core advantages of high aluminum thermal storage balls

Compared to traditional refractory brick lattice or other materials for heat storage, high alumina balls (usually refer to Al2O3 purity between 60% and 99%) showed unparalleled advantages:

1. Extremely high heat storage capacity

Principle: High alumina materials have high specific heat capacity and bulk density. The dense structure of high alumina balls allows them to store more heat per unit volume.

Effect: This means that higher heat storage can be achieved in a smaller volume, allowing for the design of more compact heat storage chambers or extending the single commutation cycle under the same conditions, improving system stability.

2. Excellent thermal shock stability

Principle: Under the working conditions of the refinery furnace, the heat storage body needs to undergo a severe temperature cycle from room temperature to thousands of degrees Celsius, and then from thousands of degrees Celsius to room temperature within a few minutes or even tens of seconds. High alumina balls, especially spheres that have been scientifically proportioned and sintered at high temperatures, have a low coefficient of thermal expansion and high toughness, which can effectively resist thermal stress caused by rapid cooling and heating.

Effect: Greatly extends the service life, reduces the risk of pulverization and blockage of airflow channels caused by thermal shock rupture, and ensures long-term stable operation of the system.

3. Excellent high-temperature structural strength and creep resistance

Principle: Under long-term high temperature (>1000 ℃) and load (upper packing pressure), ordinary materials are prone to softening deformation (creep). High alumina balls, especially products with alumina content exceeding 90%, can maintain extremely high strength and hardness in their crystal structure at high temperatures.

Effect: It prevents the thermal storage bed from being crushed or collapsed during long-term operation, ensures smooth airflow channels, and maintains the required pressure loss and heat transfer efficiency for system design.

4. Large specific surface area and efficient heat transfer rate

Principle: Countless small balls are randomly stacked to form uniform, dense, and highly specific surface area pore channels in the heat storage chamber. When smoke/air flows through these channels, it undergoes intense convection and radiative heat transfer with the surface of the sphere.

Effect: The large heat transfer area and short heat transfer path make heat exchange very rapid and sufficient, which is the fundamental reason for achieving efficient and fast direction change.

5. Excellent chemical resistance

Principle: Refinery flue gas often contains corrosive components such as alkaline dust, sulfur oxides, and zinc vapor. The main component of high alumina materials is neutral and slightly acidic Al₂O3, which has good resistance to alkaline substances and some acidic substances.

Effect: Reduced surface melting, slagging, or structural damage caused by chemical erosion, maintaining the cleanliness and heat transfer performance of the thermal storage body.

6. Uniform airflow distribution and controllable resistance

Principle: The random stacking structure of spherical fillers enables self distribution of airflow during passage, avoiding local airflow short circuits or dead zones.

Effect: The utilization rate and heat transfer efficiency of the entire thermal storage bed tend to be consistent. At the same time, by selecting spheres of different diameters (such as 12mm, 20mm, 25mm, etc.), the airflow resistance of the system can be accurately controlled, optimizing the energy consumption of the fan.