Technical article

2023-07-07

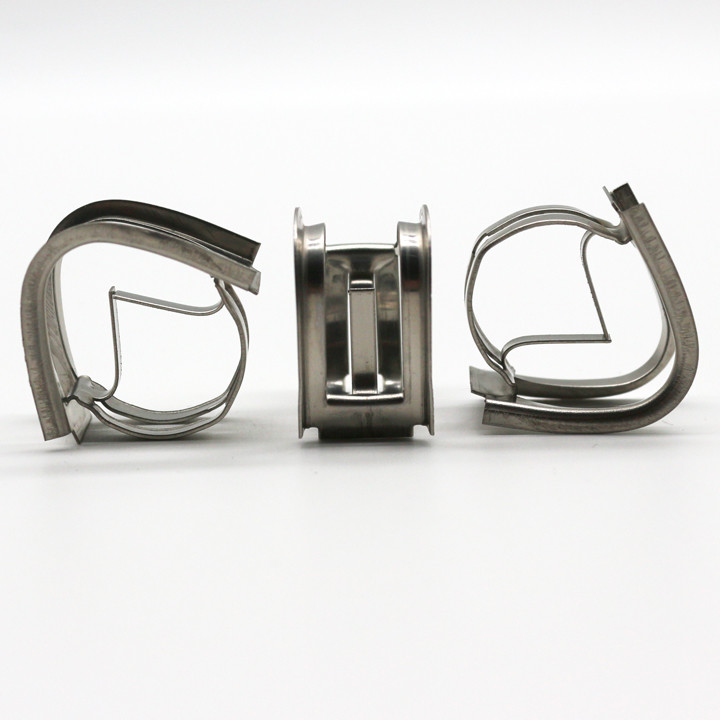

The metal intalox saddle is developed by Norton Company in the United States, and its shape is between the ring and saddle shape, thus combining the advantages of both. In terms of structure, the metal intalox saddle ring adds circular ribs on the saddle foundation to avoid overlap, ensure a certain strength and rigidity, punch out several small claws, increase gas-liquid stirring, and strengthen mass transfer, resulting in performance.

The metal intalox saddle shape is abbreviated as Interlock packings, it also be called IMTP packing. This new type of packing is used for equipping new packed towers, with a height reduction of 35%, a diameter reduction of 30%, or an efficiency improvement of 10-30%, and a pressure loss reduction of 20-60% compared to plate towers. Experimental research on replacing wet distillation with dry distillation has shown that it can reduce investment by 20%. In short, adopting a new type of ring saddle can increase yield, reduce energy consumption or cost, and improve separation efficiency.

There are various materials available for metal intalox saddle, such as carbon steel, stainless steel 304, 304L, 410, 316, 316L, etc., to be choosen.

1. Metal intalox saddle is a type of filler that can be widely used in distillation, absorption, and other reactions.

2. Metal intalox saddle rings can be used in both vacuum towers and high-pressure towers.

3. The metal intalox saddle ring can be suitable for mass transfer towers with different diameters. It is often used in vacuum towers, where low pressure drop is critical. It is also often used in high-pressure towers, with a capacity significantly exceeding that of typical trays.

The following is a case study of one of our clients purchasing our metal intalox saddle ring packing.

The saturated hot water tower in the production of synthetic ammonia is the key equipment for recovering the heat of the transformation system. The purchased metal intalox saddle ring packing tower with the specification of D70mm has been in normal use so far. The temperature difference between the hot water entering the saturation tower and the half Water gas exiting the tower is ≤ 5, and the pressure difference is close to zero, which meets the process design and use requirements.

The diameter of the saturated hot water tower is 4m, and the height is about 19.51m. The metal intalox saddle ring packing layer is 6.5m for the saturated tower, and 6m for the hot water tower. The required packing volume is 19.5m3. Since its operation, after several years of production practice, it has been proven that the use of metal intalox saddle ring packing in hot water towers is good, achieving the expected results and achieving considerable economic benefits.

The application of metal intalox saddle rings in saturated hot water towers has four characteristics:

1. High gas flow and low resistance

2. High mass transfer efficiency, good heat transfer and separation effect, and large operating elastic coefficient.

3. Cold and hot resistant, acid and alkali resistant, pressure resistant, non fragile, easy to clean, and long service life.

4. Due to its shape characteristics, this packing rarely forms voids and overlaps in the filler layer, which can greatly reduce the phenomenon of channel flow and wall flow. At the same time, it has high surface utilization rate, high mechanical strength, and excellent fluid performance.

Therefore, the metal intalox saddle ring is currently an ideal packing material for the saturated hot water tower of synthetic ammonia, and it is also one of the measures that should be promoted and applied in the consumption reduction work of small nitrogen fertilizer plants.

Jiangxi OIM Chemical Co., Ltd also produce raschig ring, pall ring, cross partion ring etc, and material is plastic, ceramic and metal. Welcome all the customers contact us via www.oimchem.com or send email to info@oimchem.com.