Technical Guide to Molecular Sieve Regeneration?

2025-06-10

As specialists in industrial desiccants and adsorbents, we understand that molecular sieves represent a significant investment for your operations. Their unmatched ability to selectively adsorb molecules based on size is critical for drying gases and liquids, separating compounds, and purifying streams. However, like any powerful tool, they require proper maintenance. **"Generating" a molecular sieve doesn't refer to its initial manufacturing, but to the vital process of *regeneration* – restoring its adsorption capacity after it becomes saturated. This technical guide explains the core principles and best practices for effective molecular sieve regeneration, ensuring optimal performance, longevity, and cost-efficiency for your operations.

Understanding Saturation: Why Regeneration is Essential

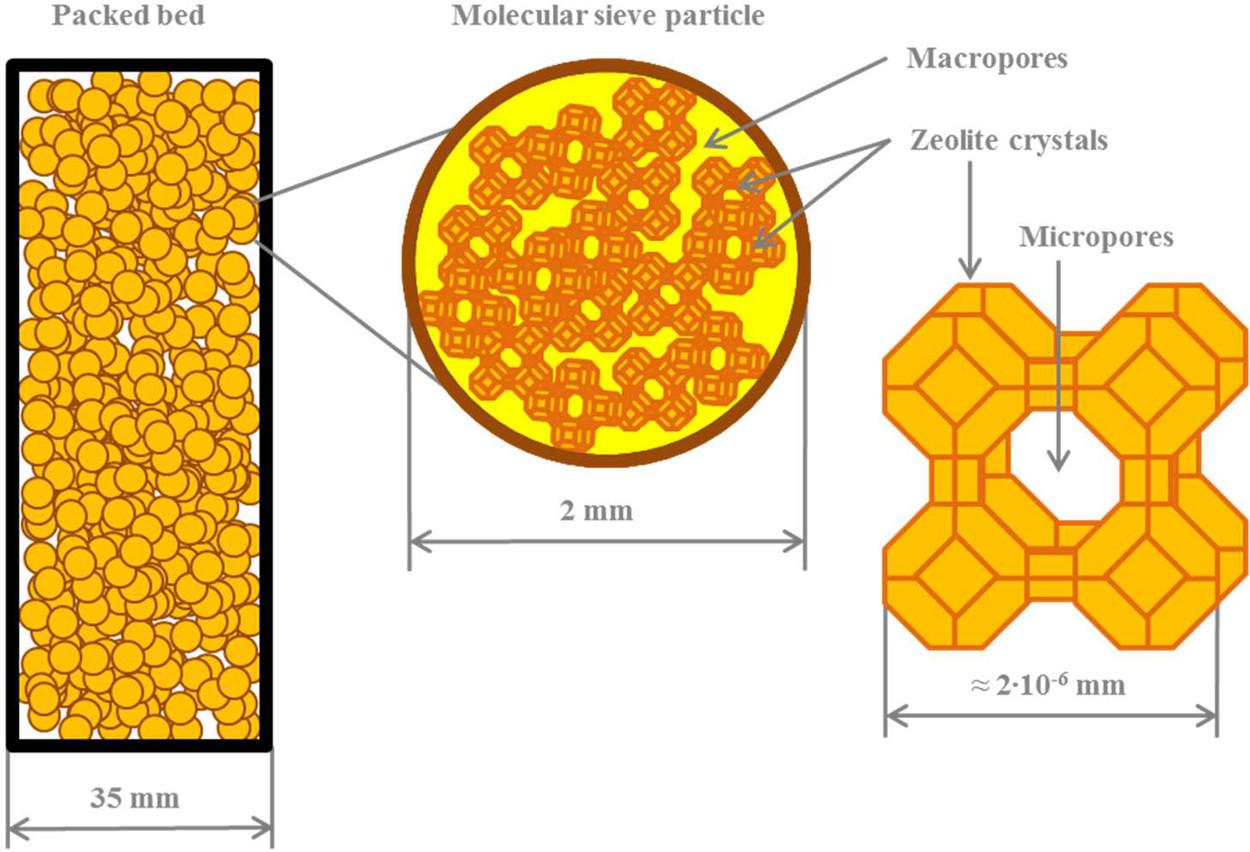

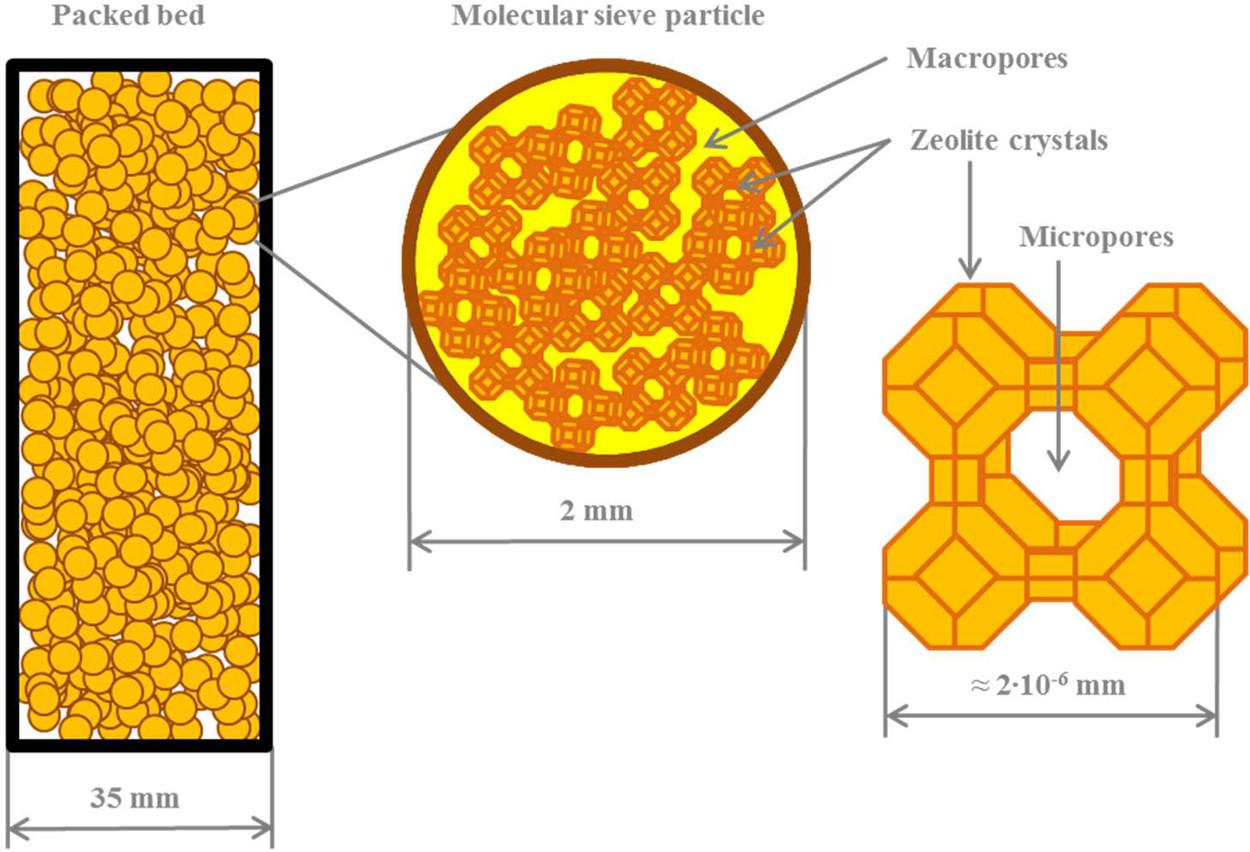

Molecular sieves are crystalline alumino silicates (zeolites) or other materials with a uniform, microporous structure. During application, water vapor, hydrocarbons, CO₂ or other molecules enter these pores and are held by adsorption forces.

Saturation Point: Eventually, the pores fill up, drastically reducing the sieve's adsorption capacity. Its "breakthrough" point is reached when target molecules start appearing in the outlet stream.

Consequence: Continued use beyond saturation leads to process inefficiency, product contamination, and potential catalyst poisoning downstream.

The Science of Regeneration: Releasing the Bound Molecules

The working principle of regeneration is reversing the adsorption process. It involves applying energy to overcome the forces holding the adsorbed molecules within the pores, allowing them to desorb and be removed. The primary method is **Thermal Regeneration (Temperature Swing Adsorption - TSA)**:

1. Depressurization & Purging (If Applicable): For pressurized systems, safely reduce pressure. Introduce a clean, hot purge gas (commonly nitrogen or dry air) to begin displacing any bulk fluid and initiate heating. This purge gas is critical for carrying away desorbed molecules.

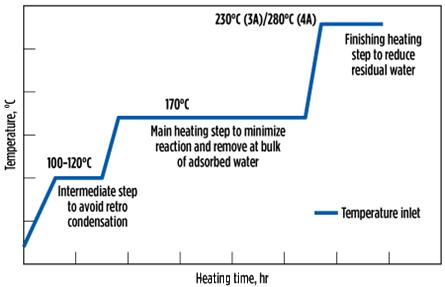

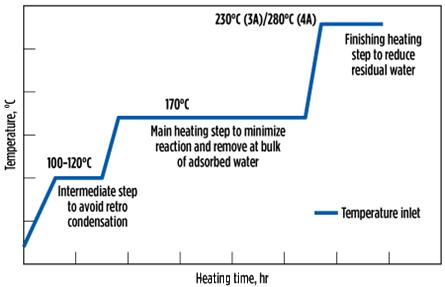

2. Heating Phase

* Temperature: This is the MOST critical parameter. Temperature must be high enough to provide the energy required for desorption but low enough to avoid damaging the sieve's crystal structure. Below is typical ranges:

# 3A, 4A, 5A molecular sieves: 200°C - 350°C (392°F - 662°F)

#13X Sieve: 250°C - 350°C (482°F - 662°F)

#Always consult manufacturer specifications. Exceeding the max temperature causes permanent damage ("hydrothermal collapse").

* Heating Rate: Controlled heating (e.g., 25-50°C/hour) is essential to prevent thermal stress, cracking of beads/pellets, and uneven regeneration.

* Purge Gas Flow: Sufficient flow is needed to efficiently sweep desorbed molecules (especially water) out of the bed. Low flow leads to re-adsorption or inadequate regeneration. The purge gas must be dry and non-reactive.

3. Soak/Hold Phase: Once the target regeneration temperature is reached throughout the bed, maintain it for a sufficient "soak" time (typically 2-8 hours, depending on bed size and saturation level). This ensures complete desorption from the deepest pores.

4. Cooling Phase

* Cooling Rate: Controlled cooling (similar rate to heating) is vital to prevent thermal shock and condensation.

* Dry Purge Gas: Continue flowing clean, DRY purge gas (usually nitrogen for critical applications) during cooling. This is paramount, introducing moisture or contaminants to the hot sieve will cause immediate, strong re-adsorption, ruining the regeneration effort. Cool the bed to near process temperature before putting it back online.

Key Factors for Successful Regeneration:

* Moisture Content of Purge Gas: The single biggest factor affecting final regenerated capacity. Purge gas dew point must be significantly lower than the required outlet dew point of the process.

* Regeneration Temperature & Time: Must be optimized based on sieve type, adsorbed species, and desired residual loading. Higher temps generally allow shorter times, but risk damage.

* Purge Gas Flow Rate: Must be adequate for heat transfer and mass removal.

* Bed Design: Ensures uniform flow distribution to avoid channeling (where gas bypasses sections of the bed).

* Initial Saturation Level: Heavily loaded sieves require longer regeneration times/higher energy input.

Alternative Regeneration Methods (Less Common for Standard Sieves):

* Pressure Swing Adsorption (PSA): Primarily used in specialized gas separation processes where the sieve has high selectivity and the adsorbed component is readily released by reducing pressure. Requires specific sieve types and complex valving.

* Purge Gas Stripping: Can be used for very weakly adsorbed species or as part of a TSA cycle, but generally insufficient for deep dehydration on its own.

Critical Considerations & Troubleshooting

* Preventing Hydrothermal Damage: Never expose hot molecular sieves (>100°C / 212°F) to liquid water or high-humidity gas. Always use dry purge during cooling.

* Adsorbed Contaminants: Oils, heavy hydrocarbons, or mercaptans can "poison" sieves, blocking pores permanently or requiring very high (often damaging) temperatures for removal. Pre-filtration is crucial.

* Incomplete Regeneration: Often caused by insufficient temperature, time, purge flow, or moisture in the purge gas. Results in reduced capacity and shorter cycle times.

* Attrition: Excessive gas velocity during heating/cooling or thermal cycling can cause mechanical breakdown (attrition) of beads/pellets, increasing pressure drop.

* Cycle Life: Even with perfect regeneration, sieves gradually lose capacity due to trace poisoning, structural stress, or attrition. Monitor performance decline.

Proper regeneration is not just a maintenance task; it's fundamental to achieving the performance, longevity, and cost-effectiveness expected from molecular sieves. Understanding the principles of thermal regeneration – emphasizing controlled heating, sufficient hold time, adequate dry purge gas flow, and meticulous dry cooling – is key. By adhering to manufacturer guidelines and optimizing your regeneration protocol based on the specific sieve type and process contaminants, you ensure reliable dehydration and separation performance cycle after cycle.

Partner with Experts for Optimal Performance

As the trusted supplier, we provide more than just high-quality molecular sieves. We offer comprehensive technical support to help you design and implement effective regeneration strategies tailored to your specific application. Contact our technical team today to discuss your molecular sieve needs and ensure you're getting the maximum value and performance from this critical technology. Let us help you keep your processes dry, pure, and efficient.