Technical article

2025-08-17

If you are using air separation equipment such as oxygen concentrators and nitrogen generators, then molecular sieve is definitely not unfamiliar. It is one of the most core components in the air separation pre-processing system and is known as the "guardian angel" of air separation equipment. The quality of molecular sieves determines the purity of the final product gases (oxygen, nitrogen, etc.), the operational stability of equipment, and energy consumption directly.

The following article will introduce the commonly used types of molecular sieves in air separation equipment, their application scenarios, and ultimately provide practical customer feedback and guidance.

1、 What is molecular sieve? Why does the air separation equipment need it?

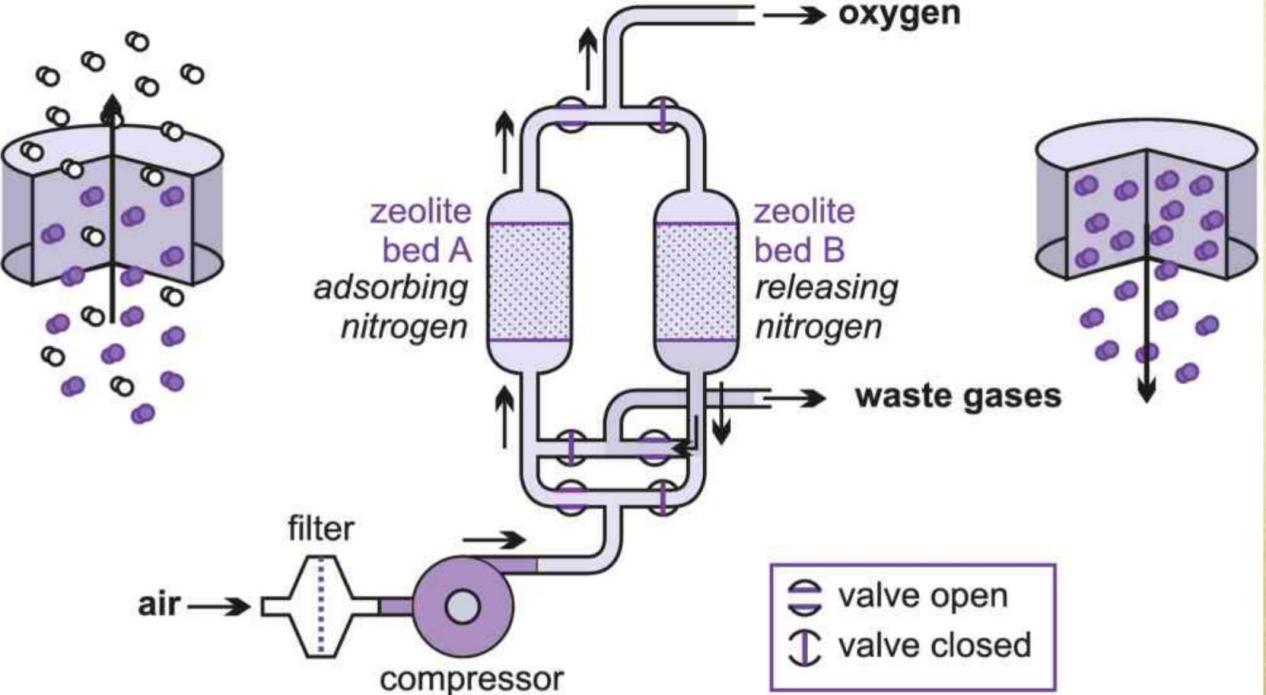

We can imagine it as an extremely small, uniformly sized 'sieve' with holes. Its working principle is to preferentially adsorb: Some molecules in the air (such as water vapor, carbon dioxide) with a diameter smaller than its pores will be "screened" and firmly grasped; If the molecular diameter of nitrogen and oxygen is larger, they can pass through smoothly.

The air contains impurities such as moisture, carbon dioxide, hydrocarbons, etc. If these impurities enter the low-temperature heat exchanger and distillation tower of the air separation unit, they will bring catastrophic consequences:

*Water vapor can freeze, block flow channels, significantly increase energy consumption, and even force production shutdowns.

*Carbon dioxide can dry ice and also cause blockage.

*The accumulation of hydrocarbons at low temperatures poses a risk of explosion.

Therefore, these impurities must be thoroughly removed before the air enters the cold box. This is the core task of the Molecular Sieve Purification System -- molecular sieve.

2、The two commonly used types of molecular sieves in air separation equipment

Although there are various types of molecular sieves, the two most commonly used ones in large and medium-sized air separation equipment are as follows:

1).Molecular sieve 13X APG

Characteristics: This is the most classic and widely used molecular sieve for air separation. Its pore diameter is about 10 angstroms, which can effectively adsorb water, carbon dioxide, and most larger hydrocarbon molecules (such as acetylene and propane).

Core advantages: Strong comprehensive adsorption capacity, especially high adsorption capacity for carbon dioxide, stable and reliable performance, mature technology.

Application location:

*The preprocessing system of the vast majority of conventional air separation equipment.

*In situations where there are strict requirements for removing carbon dioxide content from the air.

*It is the "standard configuration" and "main force" in the field of air separation.

2). Lithium type molecular sieves (such as LiX series)

*Characteristic: This is a modified and upgraded product. By replacing sodium ions (Na+) in traditional molecular sieve 13x with lithium ions (Li⁺), its crystal structure has been altered, resulting in extremely strong affinity and high adsorption capacity for water molecules.

*Super water absorption: The water absorption per unit weight of lithium based molecular sieve is 50% or even more higher than molecular sieve 13X APG.

*Energy saving and consumption reducing: A higher adsorption capacity means that when dealing with the same amount of air, the loading amount of molecular sieves can be reduced or the adsorption cycle can be extended, thereby reducing the consumption of regenerated gas (heating gas used for desorption) and directly reducing operating costs.

*Stronger acid resistance: When dealing with occasional acidic gases (such as SO₂, NOx) in the air, it exhibits greater stability and longer lifespan.

*Large and extra large air separation equipment: The energy-saving benefits are very significant.

*High humidity environment: In coastal areas with long rainy seasons, its super absorbent ability is fully demonstrated.

*Projects that are sensitive to energy consumption and operating costs.

*As a layer of protection, it is used in combination with activated alumina to form a composite bed and leverage their respective advantages.