Technical article

2025-07-15

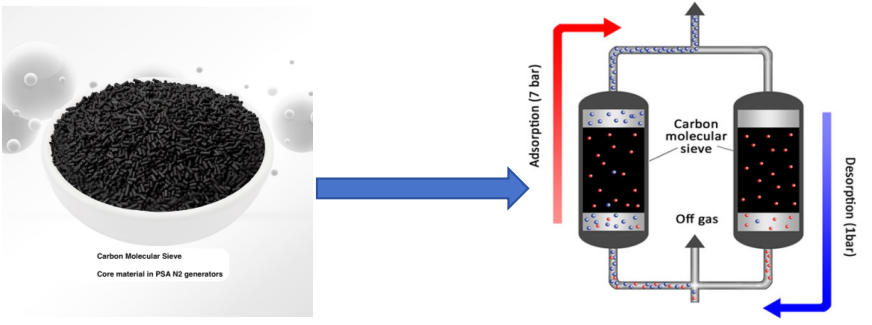

With the increasingly widespread application of industrial nitrogen in the fields such as chemical engineering, electronics, and food preservation etc, carbon molecular sieve (CMS), as the core material of pressure swing adsorption (PSA) nitrogen technology, determines the purity of nitrogen and system energy efficiency directly based on its performance. Below article will include into the working principle, regeneration characteristics, and technological breakthroughs of carbon molecular sieves, providing sustainable nitrogen solutions for industry users.

1. Carbon Molecular Sieve: The "Core Engine" for Efficient Nitrogen Production

Carbon molecular sieve extracts high-purity nitrogen gas (purity up to 99.9995%) from compressed air through dynamic adsorption separation technology. Its core advantages lie in:

- Selective adsorption: Utilizing the adsorption speed difference between oxygen molecules (diameter 3.46 Å) and nitrogen molecules (3.64 Å), carbon molecular sieve micropores (4Å) preferentially adsorb oxygen with faster diffusion rates, achieving nitrogen enrichment.

- Fast cycle: In the PSA system, the single tower adsorption time only takes 30-120 seconds, supporting continuous nitrogen production and greatly improving production efficiency.

2. Adsorption pore diameter: Precise Control of Micro porous Structure

The performance of carbon molecular sieves depends on their unique physical structure:

1) Precise micropores: Through high-temperature cracking and activation processes, a uniform pore network is formed to ensure efficient retention of oxygen molecules.

2) Surface chemical modification: Improve the synergistic adsorption ability for impurities such as water vapor and CO₂, and extend the lifespan of the filter cartridge.

3. Regeneration Technology: The Key to Extending Life and Reducing Operating Costs

The regeneration ability of carbon molecular sieve is the economic core, the regeneration achieved through pressure release desorption (PSA):

- Pressure reduction desorption: After adsorption saturation, the pressure inside the tower drops to atmospheric pressure, and the adsorbed oxygen molecules quickly desorb;

- Reverse Blow Purification: Using partial product nitrogen reverse flushing to thoroughly remove residual impurities and restore adsorption capacity.

The regeneration rate can reach over 95%, and the service life under standardized operation exceeds 5 years, reducing equipment maintenance costs.