How to determine carbon molecular sieves need to be replaced?

2025-09-10

Carbon Molecular Sieve (CMS) is the core component of pressure swing adsorption (PSA) nitrogen generator, and its performance determines the purity, yield, and operating efficiency of nitrogen gas directly. For plants which using PSA nitrogen production equipment, a common and critical question is: when do we need to replace our carbon molecular sieves? Now we will start with the working principle of carbon molecular sieves, analyze in depth the signs of performance degradation, and provide clear replacement guidelines to help you maximize equipment efficiency and reduce operating costs.

1、Introduction and Working Principle of Carbon Molecular Sieve

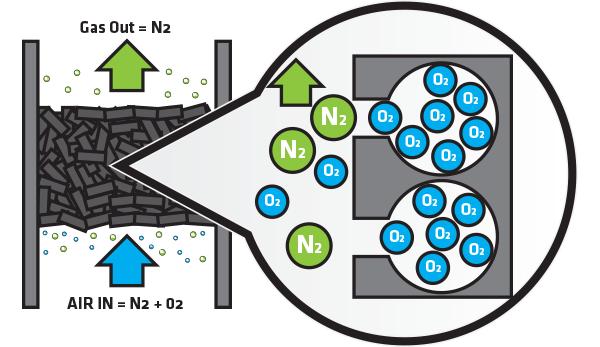

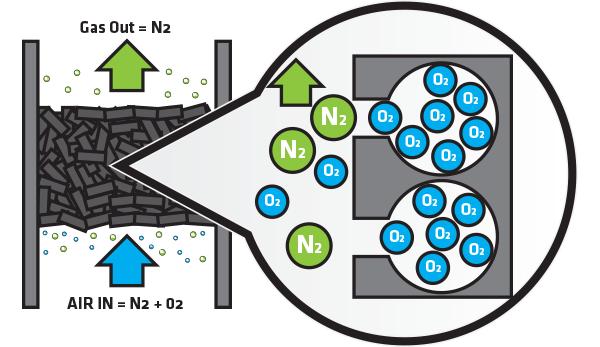

Carbon molecular sieve is a non-polar carbonaceous adsorbent, characterized by a microporous structure filled inside. The diameter of these micropores is very close to the molecular dynamic diameter of the separated gas molecules (such as oxygen and nitrogen).

In the PSA nitrogen production process, its working principle is based on kinetic separation:

*The molecular dynamic diameter of oxygen (O₂) is relatively small (about 3.46 Å), and its diffusion rate is fast, allowing it to enter the micropores of carbon molecular sieves CMS260) more quickly and be adsorbed.

*The molecular dynamic diameter of nitrogen (N₂) is slightly larger (about 3.64 Å), and its diffusion rate is slower, so most of it cannot be adsorbed and is discharged as product gas from the top of the adsorption tower.

Through a cyclic process of pressurized adsorption and depressurized desorption, the separation of oxygen and nitrogen is ultimately achieved, resulting in the desired purity of nitrogen gas.

2、Core performance indicators of carbon molecular sieve

To determine whether it failed, it is necessary to understand the key indicators that measure its performance:

* Nitrogen Production Capacity: The amount of nitrogen gas that can be produced per unit weight or volume of carbon molecular sieve in a unit time. The most direct manifestation of performance degradation is a decrease in gas production.

* Nitrogen Purity: The stable nitrogen concentration that can be obtained at the rated gas production rate (such as 99.5%, 99.9%, 99.999% etc.). The inability to meet purity standards is a clear signal of the failure of carbon molecular sieves.

* Recovery rate: Refers to the ratio of the amount of nitrogen in the product nitrogen to the total amount of nitrogen in the raw air. An efficient CMS should have a high recovery rate while ensuring purity to save energy consumption.

* Crush Strength & Abrasion Resistance: Refers to the ability of carbon molecular sieve particles to resist compression and friction. Insufficient strength can lead to pulverization, resulting in dust blocking pipelines and valves, increasing pressure drop, and seriously damaging system operation.

* Selectivity: The adsorption separation coefficient for oxygen and nitrogen. Highly selective CMS is the foundation for obtaining high-purity nitrogen gas.

3、The main reasons for the performance degradation of carbon molecular sieves

Carbon molecular sieves are not permanently used and their performance will gradually deteriorate due to the following reasons:

* Normal Aging: During long-term cycles of pressure and pressure reduction, molecular sieve particles may undergo slight pulverization due to mechanical stress, resulting in a decrease in effective adsorption area.

* Oil Pollution: The oil vapor (even in trace amounts) brought by air compressors is the "number one killer" of CMS. Oil will clog the micropores of carbon molecular sieves, causing them to lose their adsorption capacity, and this pollution is usually irreversible.

* Moisture Invasion: Although the dryer in the compressed air system is designed to remove moisture, several dryer failures or improper configurations can directly cause liquid water to enter the adsorption tower, leading to a sharp decrease in the strength of carbon molecular sieves and rapid pulverization.

*Improper operations such as frequent on-off cycles, excessive pressure, and short cycle times can accelerate the pulverization and performance degradation of carbon molecular sieves.

4、When is it necessary to replace carbon molecular sieves?

If you observe one or more of the following conditions in the nitrogen production equipment, it is likely to indicate the need to inspect and replace the carbon molecular sieve:

* Continuous non-compliance of nitrogen purity: This is the most direct signal. No matter how the equipment parameters are adjusted, the nitrogen purity cannot meet the set requirements.

* Significant decrease in nitrogen production: In order to obtain the previous rated gas production, the equipment needs to operate for a longer period of time; Or even within the rated time, the gas production is significantly insufficient to meet the demand of the gas end.

* Significant increase in pressure drop: The pressure loss in the system pipeline increases. Usually, it is due to the pulverization of carbon molecular sieves that produces dust, which clogs pipelines, mufflers, or valves. Check the exhaust port, and if a large amount of black dust is found, it can be confirmed that the pulverization is severe.

* Rapid increase in energy consumption: In order to maintain the required purity or yield, the air compressor needs to be loaded at a higher frequency, resulting in a significant increase in electrical energy consumption. Due to the decrease in adsorption efficiency, more air needs to be compressed to obtain the same amount of nitrogen gas.

* Abnormal equipment cycle time: The control system may automatically or manually adjust the adsorption and desorption time to "compensate" for the weakened adsorption capacity. If the cycle time becomes extremely short or long, it may be a problem with the CMS.

Usually, under ideal operating conditions and good pretreatment conditions, the service life of high-quality carbon molecular sieves is generally around 5-8 years. But if the front-end processing is poor (with oil or water), the lifespan may be shortened to 2-3 years or even shorter.

5、How to extend the service life of carbon molecular sieves?

* Ensure the quality of compressed air: Ensure the efficient and normal operation of the refrigerated dryer and filters (precision filters, activated carbon oil removal filters), and strictly prevent oil and liquid water from entering the adsorption tower.

* Standardized operation: Follow the operating procedures of the equipment manufacturer to avoid frequent start stop and severe pressure fluctuations.

* Regular maintenance: Regularly check the filter element and replace it in a timely manner; Check if the muffler is blocked by dust.

* Choose high-quality carbon molecular sieves: When filling or replacing for the first time, choose high strength, high adsorption capacity, and good anti pollution ability. Cheap molecular sieves may have decent initial performance, but have a short lifespan and low overall cost-effectiveness.

Jiangxi OIM Chemical is a professional supplier in adsorbent series, such as molecular sieve, activated alumina and ceramic balls etc. Welcome to check with us to get techical solutions.