Activated alumina in hydrogen peroxide production

2022-05-22

Hydrogen peroxide

activated alumina is a white,spherical, strong adsorbent, which is insoluble in water and organic solvents such as hydrocarbons and alcohols. The activated alumina produced by Jiangxi OIM Chemical Co., Ltd. is not only used for drying, air separation, but also for catalyst carrier, and has strong adsorption. It plays an important role in gas and water treatment.

Next, we will focus on telling you the principle, selection and function of activated alumina for the production of hydrogen peroxide.

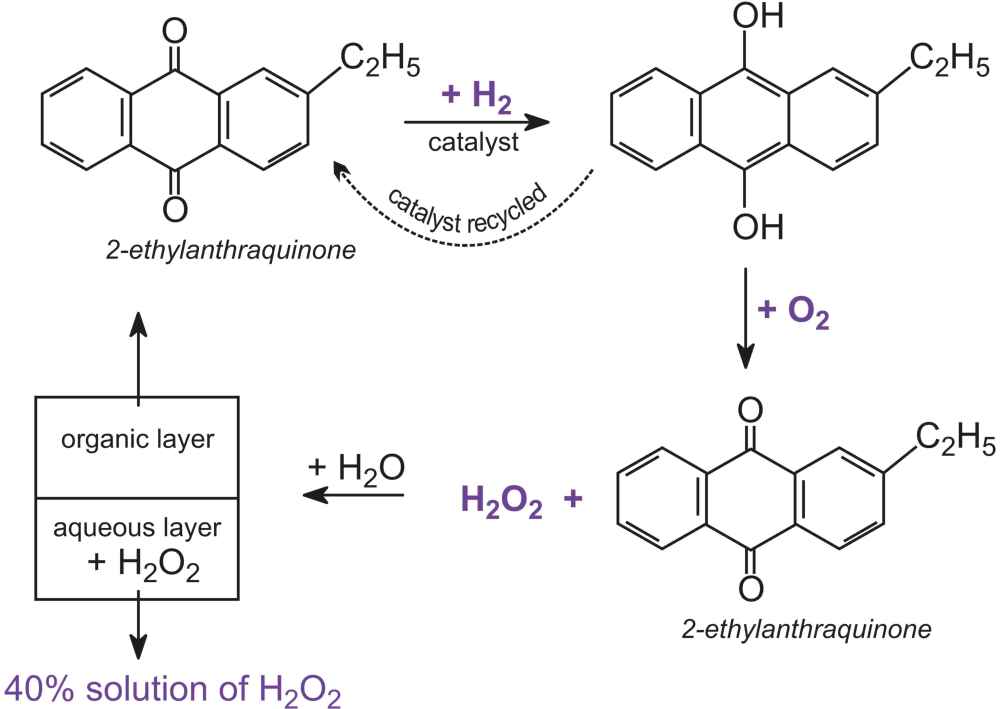

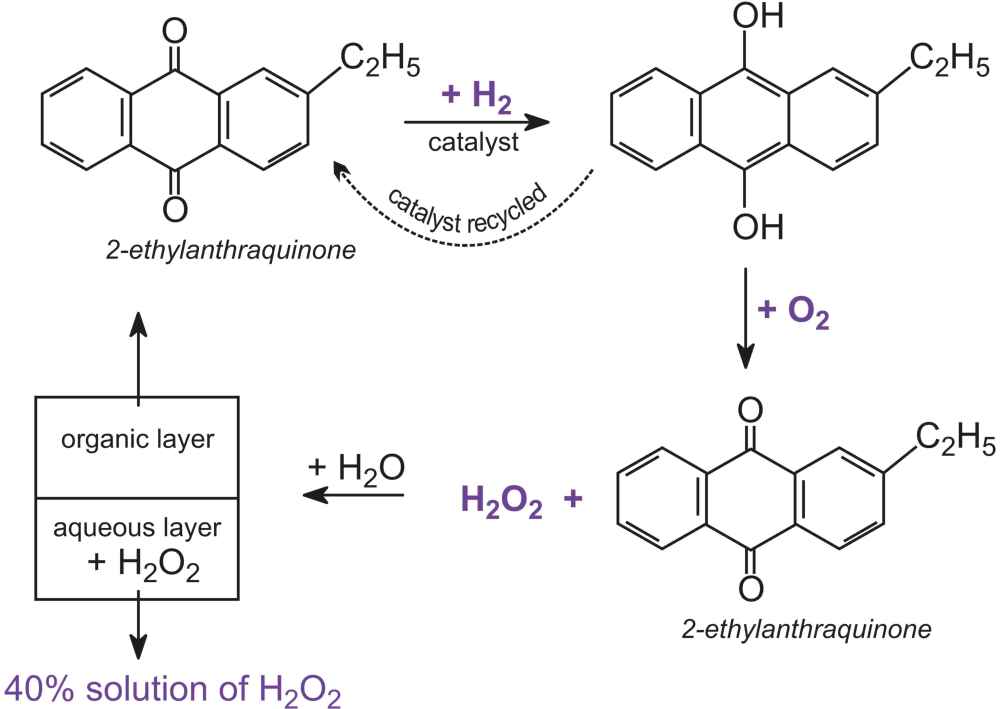

1st The production principle of hydrogen peroxide

Usually in the production of activated alumina, we use the anthraquinone method. Activated alumina is filled in the clay bed device for post-processing of the working fluid. It can adsorb the lye and water entrained in the working fluid in the post-treatment supply and demand, thereby decomposing the residual hydrogen peroxide. The most important thing is that activated alumina can regenerate some anthraquinone degradation products in the oxidation reaction and oxidation reaction.

2nd The selection of hydrogen peroxide activated alumina

The hydrogen peroxide activated alumina JXOIM-AAKA407 produced by Jiangxi OIM Chemical has strong ability to regenerate degradation products. Here are the technical indicators -- We also accept customized activated alumina.

|

Shape |

White ball |

|

Size |

mesh |

7*14 |

|

Al2O3 |

wt% |

93 |

|

Na2O |

wt% |

0.35 |

|

Fe2O3 |

wt% |

0.02 |

|

SiO2 |

wt% |

0.02 |

|

Surface area |

㎡/g |

320-350 |

|

Pore volume |

cm³/g |

0.45-0.50 |

|

Bulk density |

g/ cm3 |

0.62-0.65 |

|

Crush strength |

N/PCS |

150 |

|

Macroporosity >750A |

cm3/g |

0.18 |

|

LOI |

wt% |

5.0-8.0 |

3rd The function and replacement of activated alumina

3.1 Adsorption of lye

Activated alumina has a strong adsorption effect, and the residual alkali solution is adsorbed, so that the alkalinity of the working solution is reduced from 0.1g/L to below 0.005g/L, which is suitable for hydrogenation.

3.2 Absorb moisture

80% of the entrained water and the water produced by the decomposition of hydrogen peroxide are absorbed by the concentrated potassium carbonate solution, and a small amount of water is absorbed by the activated alumina together with the lye. After passing through the clay bed, the water in the working fluid drops below 3ml/L, but with the prolongation of the service period, the water absorption of activated alumina reaches saturation, that is, the absorption and release maintain a balance, and its water absorption effect will not be obvious.

3.3 Decomposition of hydrogen peroxide

The ability of the alkali tower to decompose hydrogen peroxide in the remaining liquid is less than 60% to 70%, and the ability of activated alumina to decompose hydrogen peroxide is 20% to 30% due to the adsorption of potassium carbonate solution.

3.4 Filtration of impurities

The activated alumina packing layer can filter the working fluid to a certain extent.

3.5 Replacement of activated alumina

Generally, two beds are connected in parallel. If it is found that activated alumina has been used for a certain period and various indicators cannot meet the production requirements, the activated alumina needs to be replaced immediately. Usually 1 ton of activated alumina can absorb about 400kg of working fluid. After the expired activated alumina is dried, if the color changes, pulverizes, agglomerates, etc., take it out immediately and refill it.