Principles of PSA nitrogen generator and carbon molecular sieve

2022-05-28

Carbon molecular sieve is a non-polar carbon material, the main component is elemental carbon, and the main raw material is phenolic resin. It’s an adsorbent for separating of oxygen and nitrogen in the air by modifying the pore structure. Nitrogen is produced by pressure swing adsorption (PSA) in industry, and it has a long service life and a wide range of applications.

So how does PSA carry out nitrogen purification? We will tell you in detail.

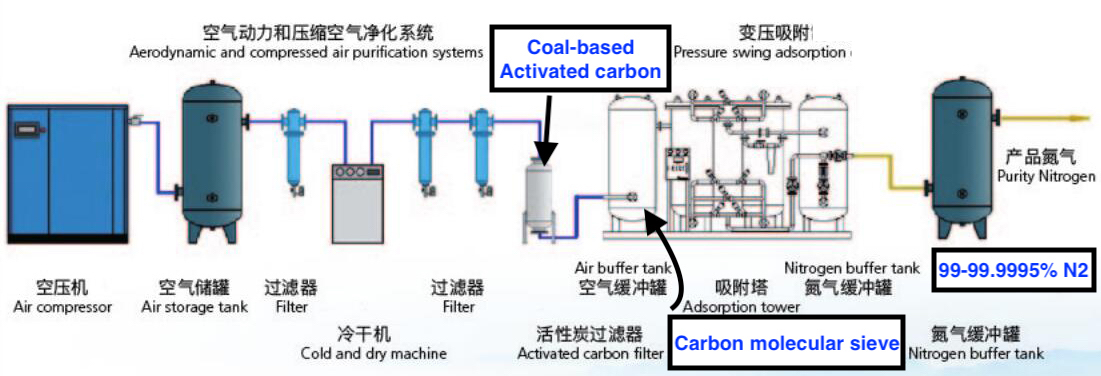

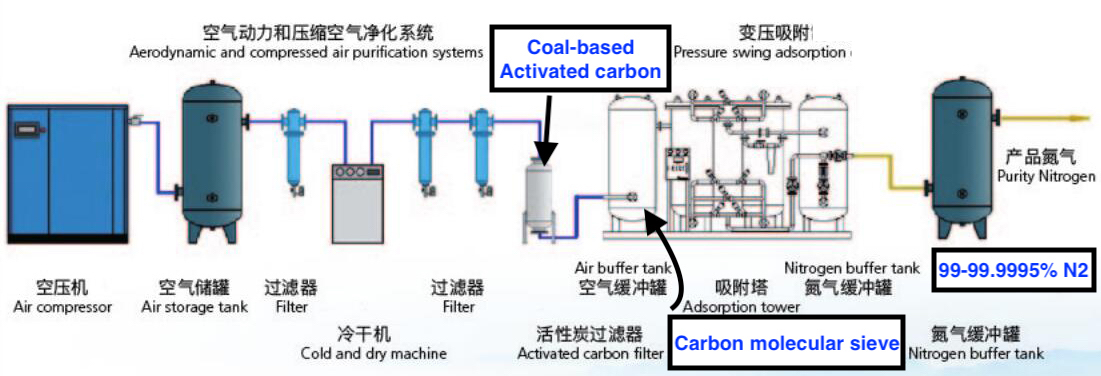

1. The basic process flow of PSA nitrogen production

After the air is compressed by the air compressor, after dust removal, oil removal, and drying, it enters the air storage tank, and enters the left adsorption tower through the air intake valve and the left suction intake valve. The tower pressure rises, and the oxygen molecules in the compressed air are removed. Carbon molecular sieve adsorption, the unadsorbed nitrogen passes through the adsorption bed, and enters the nitrogen storage tank through the left suction gas valve and the nitrogen gas production valve. This process is called left suction and lasts for tens of seconds.

After the left suction process is over, the left adsorption tower and the right adsorption tower are connected through the upper and lower pressure equalizing valves, so that the pressures of the two towers are equalized. This process is called equalizing pressure and lasts for 2 to 3 seconds. After the pressure equalization is completed, the compressed air enters the right adsorption tower through the air inlet valve and the right suction inlet valve. The oxygen molecules in the compressed air are adsorbed by the carbon molecular sieve, and the enriched nitrogen enters the nitrogen gas through the right suction outlet valve and the nitrogen gas production valve. Tank, this process is called right suction, and the duration is tens of seconds.

At the same time, the oxygen adsorbed by the carbon molecular sieve in the left adsorption tower is depressurized and released back to the atmosphere through the left exhaust valve. This process is called desorption. Conversely, when the left column is adsorbing, the right column is also desorbing at the same time.

2. The adsorbents usually need as follows:

Activated carbon - To remove oil, to avoid carbon molecular sieves contacting oil impurities, blocking the pore size, resulting in a decrease in purity and nitrogen production.

Carbon molecular sieve -- The key of nitrogen production, adsorb oxygen and produce high purity nitrogen from 99-99.9995%.

Activated alumina -- High crush strength and strong water absorption capacity, which can protect the carbon molecular sieve (the quantity used is not much, just covering the height of the tower about 5-10 cm).

3. Adsorbent replacement

1) Activated carbon filter can effectively filter oil and prolong the service life of high-quality carbon molecular sieve. Activated carbon needs to be replaced every 3000 hours or 4 months. If the use cycle is not frequent, it can be considered that it must be replaced within 1 year.

2) The carbon molecular sieve decays by 5-8% every year. If the customer does not have high requirements for nitrogen production purity and nitrogen production, it is generally replaced once every 5 to 6 years; otherwise, we recommend replacing it once every 3 to 5 years.

3) Activated alumina can protect the carbon molecular sieve. For example, before replacing the carbon molecular sieve, we recommend that the bottom of the tower be covered with activated alumina.

Carbon molecular sieve from Jiangxi OIM Chemical is a highly efficient nitrogen-producing adsorbent, which is exported to more than 30 countries. At the same time, there is also a special person to guide the installation and replacement of carbon molecular sieves. The following is the contact information, you are welcome to consult at any time.

Email:

info@oimchem.com

Website:

www.oimchem.com

Linkedin:

https://www.linkedin.com/in/oimchemical/