Technical article

2025-02-10

Keywords: molecular sieve 13X; PET drying; Deep dehydration; Food-grade packaging materials

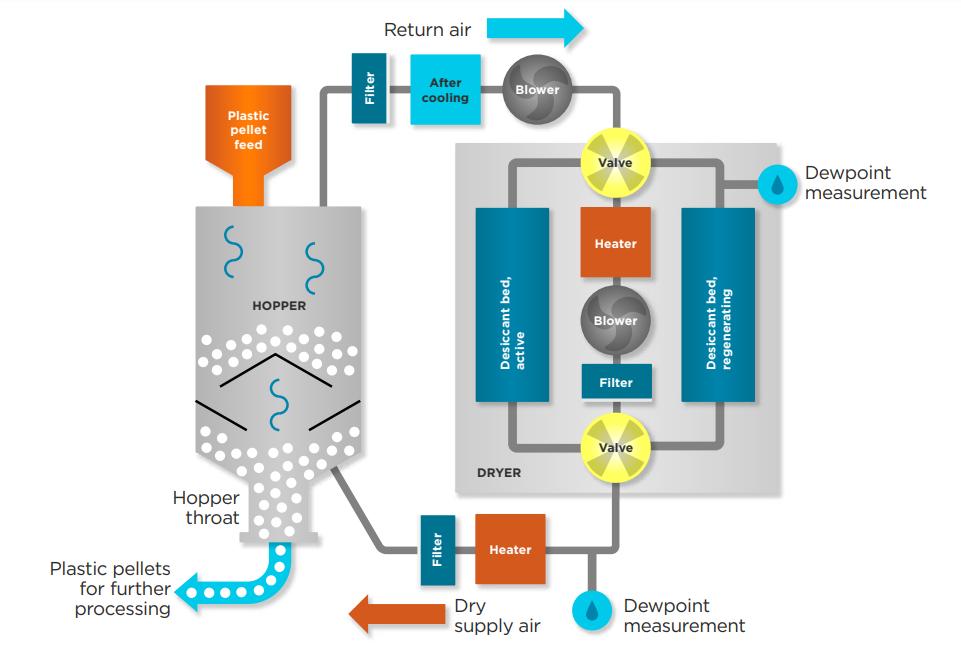

As the most widely used polyester material in the world, PET's production process directly determines product quality (such as intrinsic viscosity and color) by controlling the moisture content of raw materials. A trace amount of residual water may cause hydrolysis of PET resin during high-temperature processing, which in turn affects the molecular chain structure, leading to problems such as decreased product strength and reduced transparency. How to effectively remove the moisture in PET raw materials? We recommend 13X molecular sieve with high adsorption capacity:

Molecular sieve 13X is a synthetic aluminosilicate crystal material with a pore size of approximately 10Å (1 nanometer) and a highly ordered three-dimensional pore structure. This design has two core advantages.

1. Selective adsorption

The dynamic diameter of water molecules is about 2.8 Å, while the diameters of organic molecules (such as ethylene glycol and terephthalic acid) in PET raw materials are generally greater than 5 Å. Molecular sieve 13X can selectively adsorb water molecules through precise pore size matching, while avoiding the adsorption of effective raw material components, achieving "targeted dehydration".

2. Ultra-high adsorption capacity

Under the conditions of 25℃ and 70% relative humidity, the static water adsorption capacity of molecular sieve 13X can reach more than 25%, which is 2-3 times that of traditional silica gel desiccant. This means that less adsorbent can be used to achieve deep dehydration requirements, significantly reducing energy consumption during equipment operation.

| Index | Molecular sieve 13x | Activated alumina |

| Residue water(ppm) | ≤50 | 100~300 |

| Regeneration temp. | 250~350℃ | 150~200℃ |

| Service life | 3~5years (>2000 cycles) | 1~2 year (>500 cycles) |

| Resist organic pollution | High | Low |