Technical article

2024-11-11

Pall ring is a common packing which used in vacuum distillation towers to process materials that are thermally sensitive, easily decomposed, prone to polymerization, and prone to carbon deposition. It is mainly used in packed towers in chemical, petroleum, and other fields, and is suitable for various separation, absorption, desorption devices, atmospheric and vacuum distillation devices, synthetic ammonia decarbonization, and desulfurization systems. Under the same pressure drop, the processing capacity is more than 50% larger than that of raschig ring; under the same processing capacity, the pressure drop is reduced by half compared to rasching ring, and the mass transfer efficiency can be improved by about 20%.

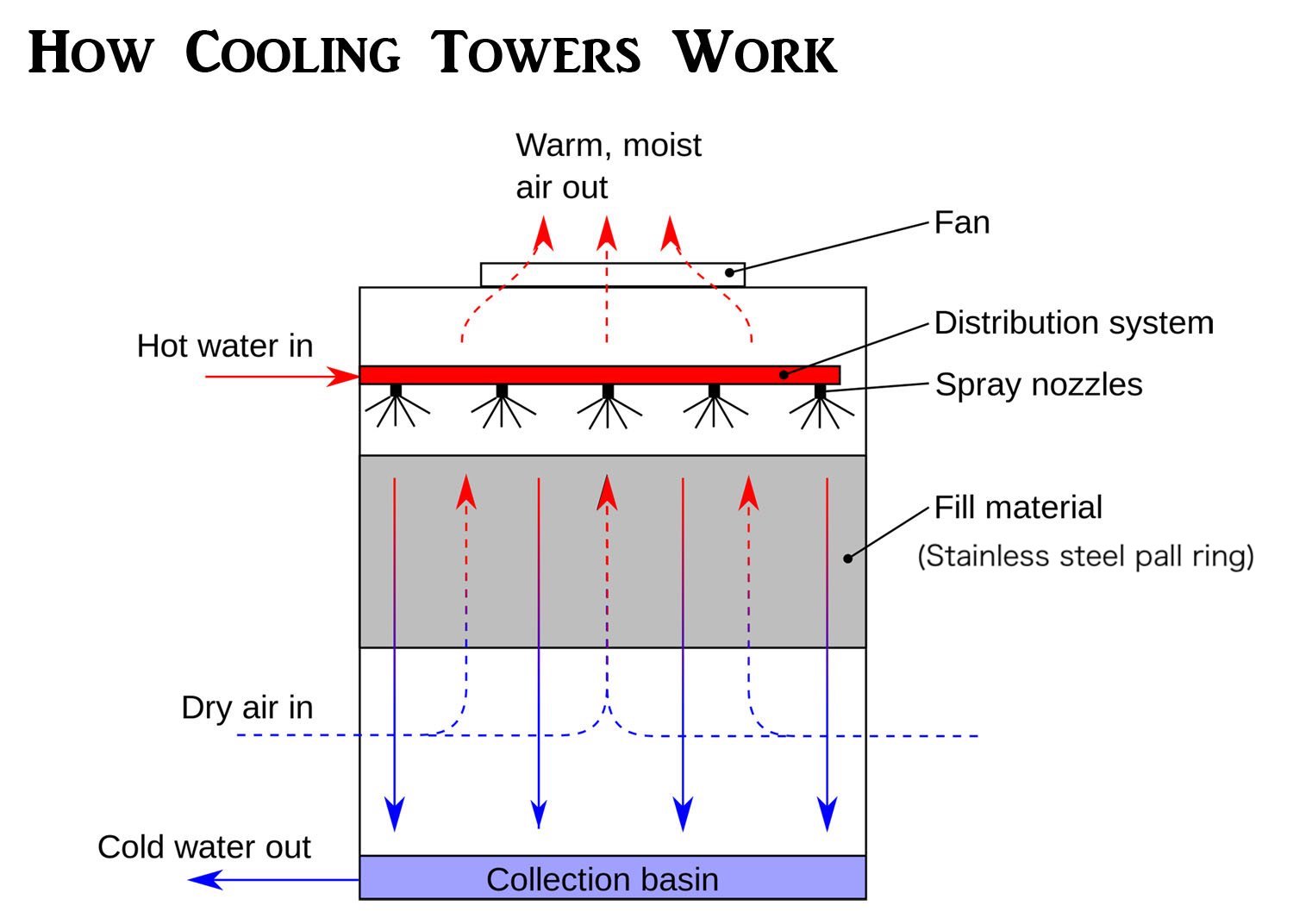

The most important component inside a packed tower is called packings, which the functions is to increase heat dissipation, prolong the residence time of the cooling tower, increase heat transfer area and heat transfer, and evenly distribute water.

So what exactly is tower packings?

As an important component in packed towers, packings provides an effective phase interface for heat and mass transfer between gas and liquid phases. The absorbed mixed gas is fed from the bottom of the tower, and the absorbing liquid is sprayed down from the top of the tower. Liquid and gas undergo gas-liquid mass transfer on the surface of the packing.

What are the main applications?

* Chemical industry: Plays the role in the separation and purification process of chemical products. For example, in fertilizer production for separating ammonia and carbon dioxide, the pall ring can increase the gas-liquid contact area, making the separation more efficient.

* In the field of petrochemicals, processes such as distillation, absorption, and desorption are used in the refining of crude oil. For example, in gasoline refining, the use of a pall ring packed tower can better separate impurities and improve gasoline quality.

* Environmental engineering: used in exhaust gas treatment and wastewater treatment. For example, when treating sulfur dioxide in factory exhaust gas, the pall ring packed tower is used to allow the exhaust gas and absorption liquid to fully contact and react, reducing harmful gas emissions.

Below is the projects which metal pall rings are used in cooling towers:

Project 1: In a methanol distillation unit of a large chemical enterprise, a metal pall ring packed tower was used. Due to the efficient mass transfer performance of the pall ring, the purity of methanol increased from around 95% to 99.5%, while also reducing energy consumption and improving production efficiency.