What is molecular sieve 13X APG?

2023-02-27

What is molecular sieve 13X APG? What is the difference between molecular sieve 13X APG and molecular sieve 13x?

Molecular sieve 13x has a pore size of 10A, and can adsorb molecules less than 10A. It can be used for the co-adsorption of catalyst carrier, water and carbon dioxide, and water and hydrogen sulfide gas. It is mainly used for the drying of medicine and air compression systems. There are different professional varieties according to different applications.

Molecular sieve 13X APG (special molecular sieve for air separation) is a special molecular sieve produced to meet the special requirements of the cryogenic air separation industry, further improve the adsorption capacity of molecular sieve for carbon dioxide and water, at the same time, it can absorb trace moisture, acetylene and other hydrocarbons in the air, and avoid the phenomenon of freezing tower during the air separation distillation process. This product is applicable to various sizes of cryogenic air separation devices, and is also widely used in compressed air industry and air separation equipment in chemical plants and steel plants. The H2O and CO2 in the air can be removed to help the cryogenic method to produce N2 and O2. At the same time, our molecular sieve 13X APG can also be used for drying and desulfurization of natural gas, liquefied petroleum gas and liquid hydrocarbon, as well as drying of common gases.

Now, I will introduce the case of a customer who we had been worked with in the past few years. They mainly use molecular sieve 13X APG for PSA hydrogen production unit.

Pressure Swing Adsorption (PSA) is a new gas adsorption and separation technology. Initially, it was mainly used for air drying and hydrogen purification in industry. The technology for oxygen or nitrogen production from air was developed after 1970. After 1976, carbon molecular sieves or vacuum pressure swing adsorption of zeolite molecular sieves were gradually developed to produce oxygen or nitrogen from the air. In 1980, single-bed PSA adsorption was realized to produce medical oxygen.

Among them, the adsorbents commonly used in PSA devices include silica gel desiccant, activated alumina ball, molecular sieve 13X APG , activated carbon, carbon molecular sieve, molecular sieve 5A , molecular sieve 4A etc.

Through the production process of pressure swing adsorption hydrogen production unit, the pore size distribution and pore volume of the adsorbent - special molecular sieve 13X APG for pressure swing adsorption are controlled, and the surface physical and chemical properties of the adsorbent are changed, so that it has the characteristics of large adsorption capacity, fast adsorption and decarbonization, strong adsorption selectivity, high separation coefficient, and long service life.

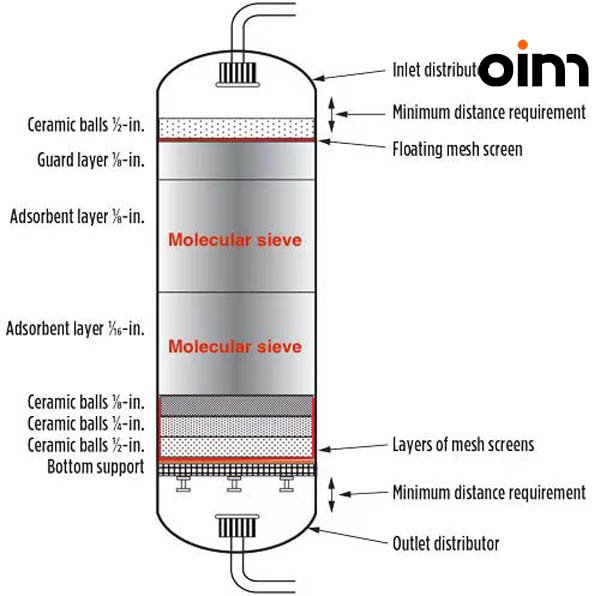

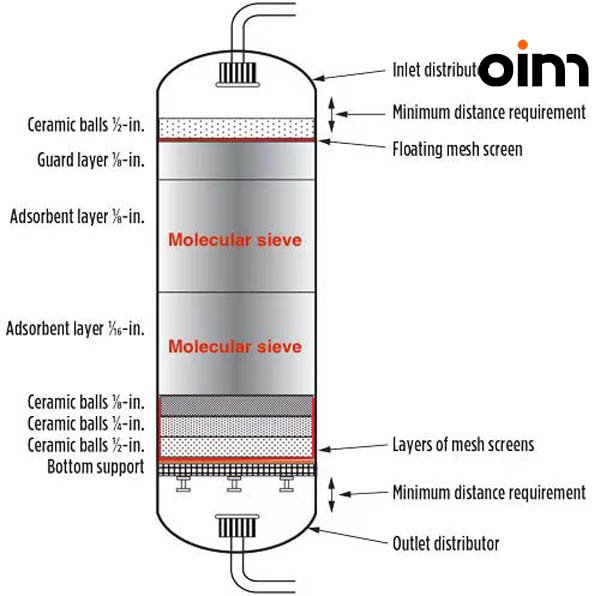

The special molecular sieve 13X APG for PSA hydrogen production unit and the compressed air from the air compressor first enter the cold dryer to remove moisture, and then enter the PSA hydrogen production unit composed of two adsorption towers. The special molecular sieve 13X APG adsorbent for PSA loaded in the tower is used to selectively adsorb O2, CO2 and other impurity gas components, and as product hydrogen, it will be discharged from the tower top with a purity of 99%. During depressurization, the oxygen adsorbed by the adsorbent is desorbed and discharged through the reverse discharge at the bottom of the tower. After purging, the adsorbent can be regenerated. After the regeneration of PSA hydrogen production unit, the adsorbent can be transferred to adsorption after pressure equalizing and product boosting. The two towers are used alternately to achieve the purpose of continuous separation of air to produce hydrogen.

Jiangxi OIM Chemical also produce other series of molecular sieve, such as molecular sieve 13x HP, lithium molecular sieve, carbon molecular sieve etc. Should any one have such interest, just contact us to talk more.

Web.: www.oimchem.com

Email: info@oimchem.com