Classification and application of inert ceramic balls

2023-02-16

When talk about ceramic balls, people in the chemical industry are no strangers. The ceramic balls can be divided into three categories in terms of technology, production process and use methods. Now Jiangxi OIM Chemical Co., Ltd will show you the application scope and specific use of these three types of ceramic balls.

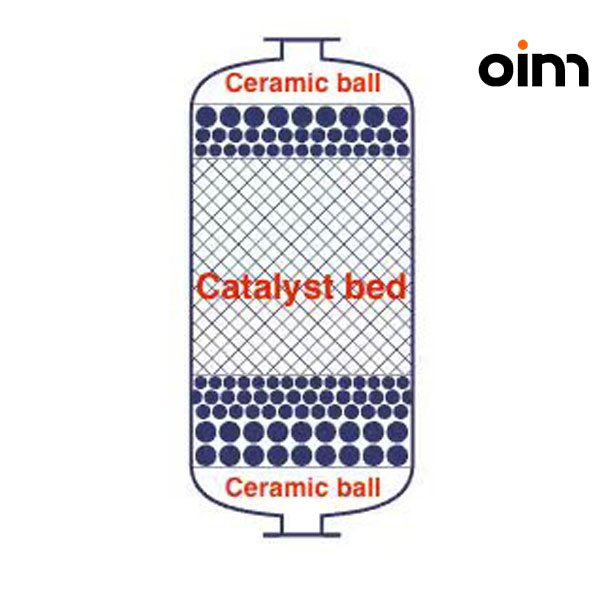

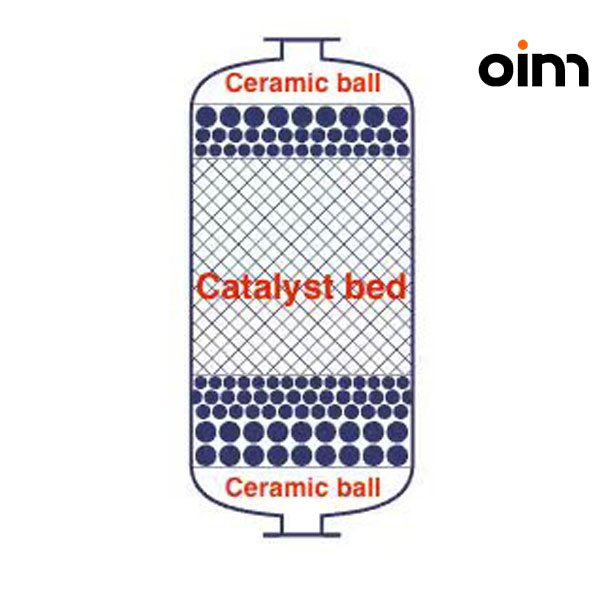

1. Inert ceramic balls are used in petroleum, chemical, fertilizer, natural gas, environmental protection and other industries. They are used as covering and supporting materials for catalysts in reactors and tower fillers. The main role of the filler ceramic balls is to increase the gas or liquid distribution points, support and protect the active catalyst with low strength. According to the content and use of alumina, it can be divided into high alumina ceramic balls, medium alumina ceramic balls, ordinary ceramic balls, perforated ceramic balls, etc. Generally, the aluminum content of high-alumina ceramic ball is 90~99%; The aluminum content of medium aluminum ceramic ball is 30-80%; Common ceramic balls are divided into 17-19% and 23-26% ceramic balls containing aluminum.

2. Grinding ceramic ball is a kind of ceramic ball used for grinding. It can be used as a grinding medium. That is to say, it can be used in some grinding equipment such as ball mills. It is widely used in various grinding industries with high requirements by taking advantage of wear resistance, low pollution and low consumption. The main aluminum content is 92% grinding ball, and its surface is not smooth.

3. Thermal storage ceramic balls, which are spherical in shape, use thermal storage ceramic balls to store heat. They are suitable for the preheating of pressurized air in iron and steel plants to meet the requirements of rapid temperature rise. They can also be used for aluminum melting furnace forging furnace, etc.

The quality of inert ceramic balls is of great concern to everyone, so what factors should be used to judge their quality?

1. Compressive strength of ceramic ball: The strength of ceramic ball is a very important technical parameter. Compressive strength is tested by equipment. If the scope specified in the national standard is met, it shall be deemed as qualified.

2. Aluminum oxide content: the main components of inert ceramic balls are aluminum oxide and silicon dioxide. According to the national standard, the combined proportion of the two is more than 90%. The aluminum content is a very important test item. Because the higher the aluminum content, the higher the strength and other indicators.

3. Gloss of ceramic ball: after the ceramic ball is calcined at high temperature, if the raw material has iron and other materials that exceed the standard, there will be many stains on the surface of the ceramic ball, which will directly affect the customer's impression.