Technical article

2023-03-22

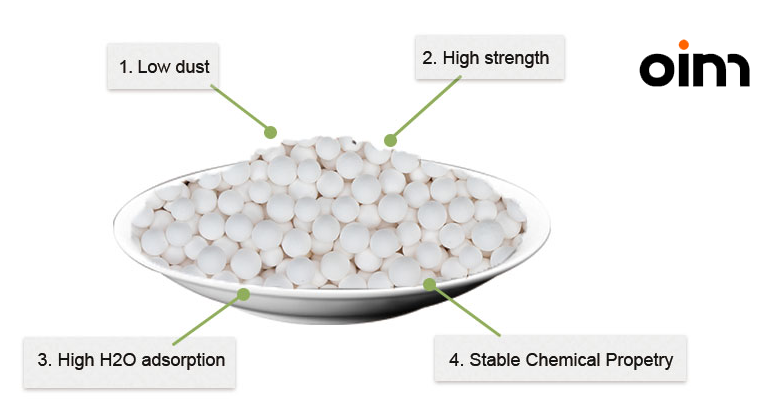

What is activated alumina? Activated alumina is also known as activated bauxite. But its main ingredient is quick-release powder. Why we called them “quick-release powder”? That's because in China, it is aluminum oxide powder produced by rapid powder dehydration method. The quick-release powder is a mixture of x-alumina and p-alumina, with different contents due to different production conditions. Activated alumina is a white spherical adsorbent, which is a porous and highly dispersed solid material made by special processes. It has a white spherical appearance, strong adsorption capacity, large specific surface area, and excellent thermal stability. It is widely used as a catalyst and catalyst carrier for chemical reactions.

So what is the adsorption principle of activated alumina?

Activated alumina will quickly dehydrate during the activation process and reversibly absorb water after activation. This adsorption is a physical adsorption process. Among all adsorbents, activated alumina has a better drying effect because of its strong adsorption capacity for water. Even at very low partial pressures or concentrations, it still has a high adsorption capacity, so you can obtain the deep drying you need no matter where you are. Under very wide operating range and dynamic conditions, activated alumina has high drying efficiency - high adsorption capacity, fast adsorption speed, good thermal stability, stable operating cycle, and no cracking when in contact with liquid.

Activated alumina desiccant is a desiccant used for deep drying of trace water, which is very suitable for heat free regeneration equipment. White spherical porous particles with uniform particle size, smooth surface, high mechanical strength, good thermal stability, stable operation cycle, strong moisture absorption, no swelling or cracking after water absorption, and strong fluorine adsorption. Mainly used for defluorination of drinking water in high fluorine areas. The adsorption effect varies with the pH value. At around pH 7.0, the adsorption effect is relatively poor, and its adsorption capacity has been significantly improved under acidic or alkaline conditions.

Can activated alumina be regenerated?

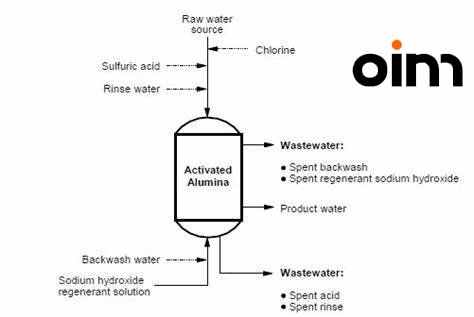

Activated alumina is one of the inorganic chemical products widely used in the world today. Due to its porous structure, high specific surface area, and unstable transition state, activated alumina has greater activity. In the petrochemical and fertilizer industries, it is widely used as a catalyst and catalyst carrier. Activated alumina also has adsorption properties, so it is used as a desiccant for gases and liquids, an adsorbent for gas purification, a fluoride remover for drinking water, and a color and odor remover for industrial wastewater.

In the drying application of activated alumina, heating regeneration method is generally used, and hot nitrogen gas is generally used for purging and regeneration. This is because of the strong interaction between water and activated alumina, it is difficult to completely desorb the adsorbed water using other methods. The heating and desorption process includes three steps: heating, flushing, and cooling. The higher the heating temperature, the more complete the desorption regeneration. Generally, the heating and regeneration temperature of activated alumina is between 180 and 350 ℃. Generally, it is sufficient to raise the temperature of the activated alumina tower to 280 ℃ for 4 hours. The heating rate is about 50 ℃ per hour. Due to the high concentration of water vapor at high temperatures that can seriously damage the structure of activated alumina, it is necessary to wash the activated alumina bed with nitrogen, air, product gas, or other suitable gases while heating. The flushing gas should strive to contain no water, as the amount of water content in the flushing gas directly affects the regeneration effect.