Installation method of ceramic intalox saddles

2023-02-03

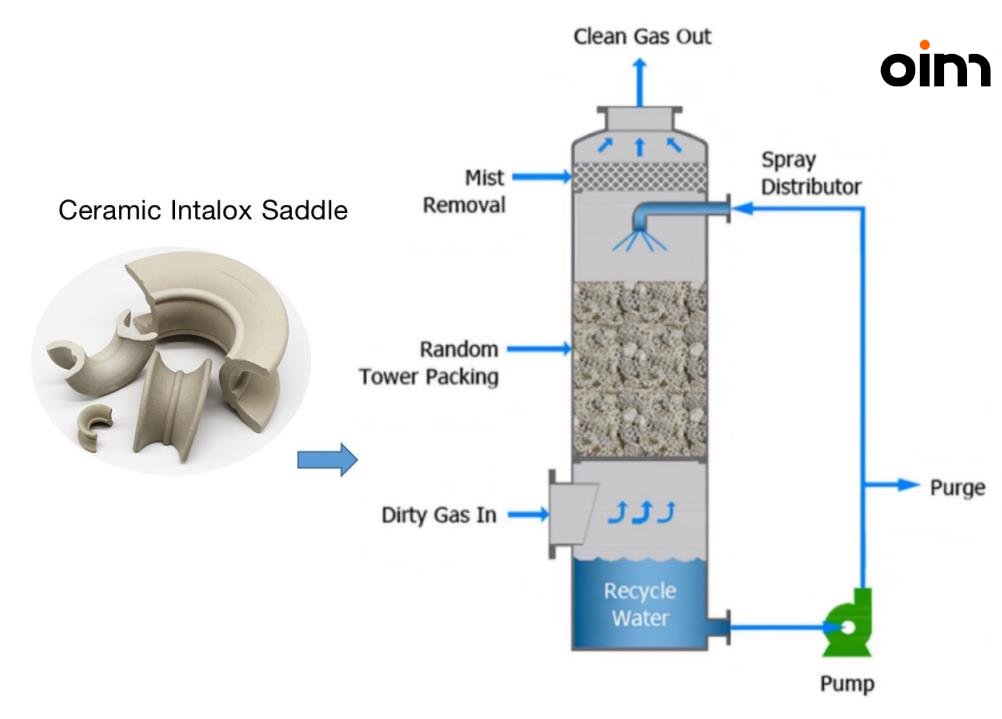

Ceramic intalox saddle is one of the ceramic tower packings, which is processed by continuous extrusion process. Compared with the same material of ceramic raschig ring, ceramic intalox saddles has the advantages of large flux, low pressure, high efficiency and so on. The ceramic intalox saddle bed has a large void ratio. Most of the beds are arc-shaped liquid channels, which reduces the resistance of gas passing through the bed and also reduces the radial diffusion coefficient of liquid flowing downward.

The ceramic intalox saddle packing bed has a large void ratio. The shape of ceramic intalox saddle packing is between ring and saddle, so it has both advantages. This structure is conducive to the distribution of liquid and the increase of civil gas channels. Because of its high density and excellent acid-resistant and heat-resistant properties, ceramic intalox saddles can resist the corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid.

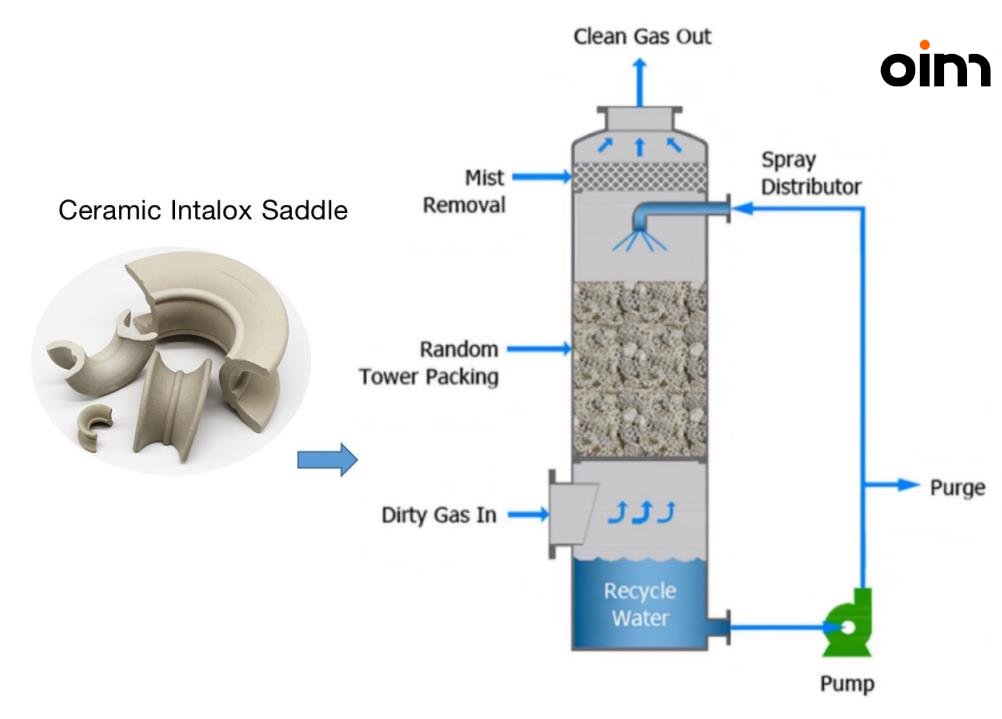

The ceramic intalox saddles is used in two main fields, but this depends on the different performance requirements of the actual application. One field is chemical and petrochemical industries, and the other is environmental protection, which is used in waste gas treatment and environmental protection equipment such as RTO thermal storage incinerator. It is commonly used in drying tower, absorption tower, cooling tower, washing tower, regeneration tower, etc. in chemical, metallurgical, gas, environmental protection and other industries.

Next, let's talk about the installation method of ceramic intalox saddles.

The installation procedure of ceramic intalox saddles seems very simple, just pour the packing into the tower. In fact, otherwise, such simple installation will cause uneven packing density, or even break the rectangular saddle ring, which will cause uneven distribution of gas and liquid and reduce the separation efficiency. Ceramic intalox saddle and non-carbon steel metal tower packings shall be filled by wet method if conditions permit. After installing the support plate, fill the tower with water, and gently pour the filler into the water from above the water surface. The packings will float and fall from the water, and the water surface should be more than 1 meter higher than the filler. In this way, the damage and deformation of ceramic intalox saddles can be reduced, and the uniformity of incoming packing can be increased. The amount of packing can be reduced by about 5%, the flux of packing will increase, and the pressure drop will decrease. The comparison experiment of wet filling and dry filling with DG38 pall ring in 500mm diameter tower shows that wet filling is less than dry filling by 5%, the pressure drop is reduced by 10%, and the efficiency is almost equal.

1. The ceramic intalox saddles should be handled with care during transportation, lifting and loading, and do not hit the filling ton bag.

2. During the whole process of shipment, pay attention to rain-proof.

3. Before entering the tower, the filling personnel must conduct oxygen content analysis, and can enter the filter only after passing the analysis.

4. Contact with the outside in time, medical and security personnel should be present, and emergency measures should be taken.

5. No items can be left in the tower.

6. When working in the tower, be careful not to damage the internals, and the accessories should be installed firmly.

7. The connection between the cloth bag and the funnel should be fastened to avoid slipping and hurting people.