How inert ceramic balls work in catalyst production

2024-10-25

In catalyst production, the common used ceramic balls are generally 99% high alumina ceramic balls and 17-19% inert ceramic balls, which have excellent chemical stability, high temperature resistance, and mechanical strength, and are suitable for supporting and covering most catalysts.

* High alumina ceramic ball (Al2O3 content of over 99%): This ceramic ball has high-temperature corrosion resistance and is suitable for use in environments with high temperature and strong acidity and alkalinity. It can effectively support and protect catalysts, prevent wear and crushing.

* Inert ceramic balls (with Al2O3 content above 17%): This type of ceramic ball has high chemical inertness and mechanical strength, which can prevent the movement, blockage, and loss of catalyst particles, and also increase the pressure balance and gas distribution effect of the reactor.

Usually, the higher the aluminum content of ceramic balls, the lower their iron content, higher compressive strength, and higher price.

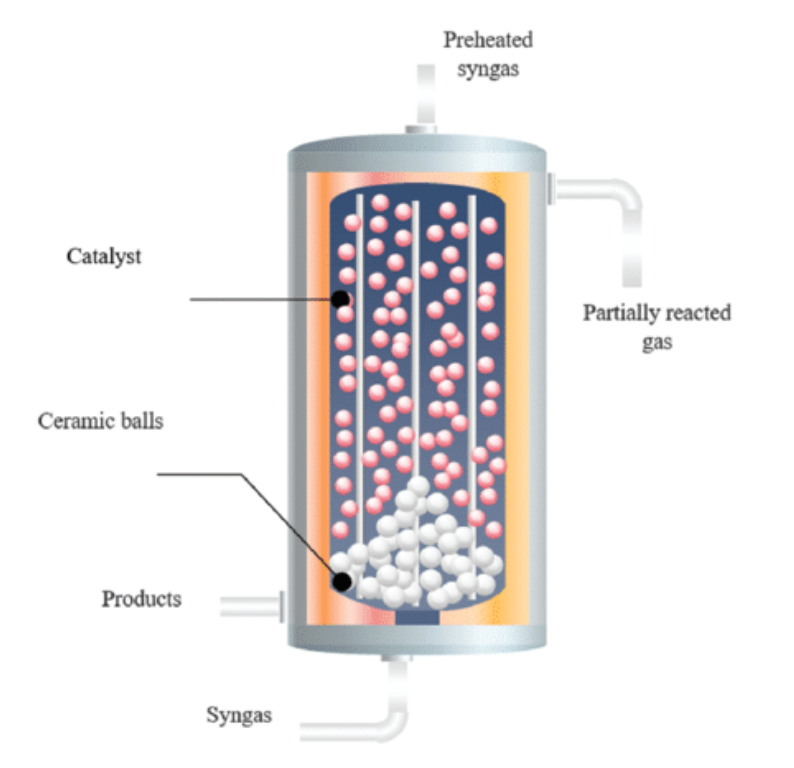

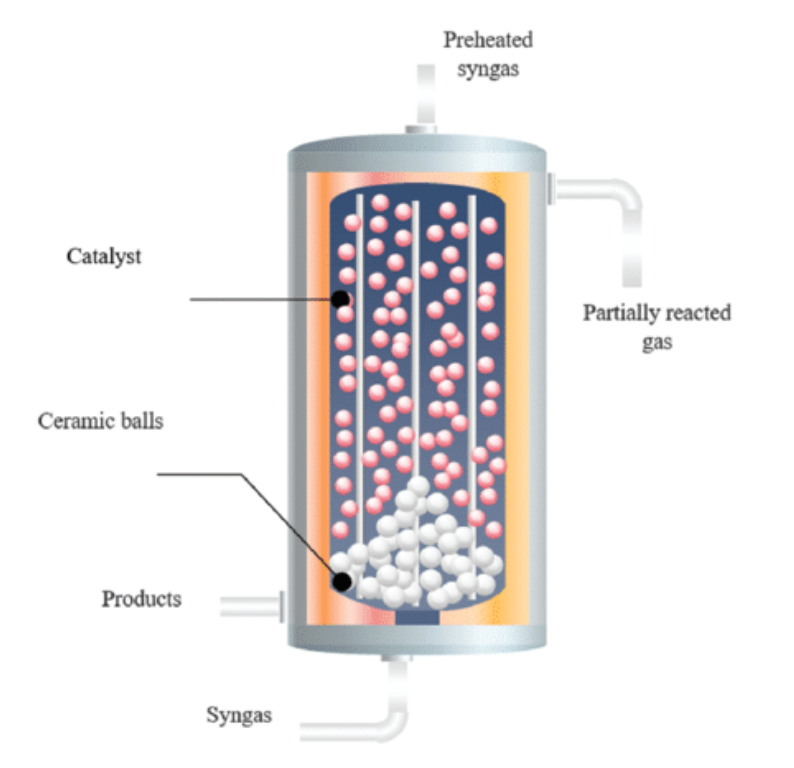

So how inert ceramic balls work in catalyst production?

1st Catalysts are with weak crush strength. Inert ceramic balls are placed in the bottom of catalyst bed, to support the catalyst bead or cyliner.

2nd The porous surface of ceramic balls can help evenly distribute gas or liquid flow, allowing it to flow better through the catalyst bed and improve reaction efficiency and uniformity.

3rd Ceramic balls is with high scrush strength, which can protect active catalysts from high pressure or impact, especially in high-pressure environments or in the presence of large particulate matter.

4th Ceramic balls can play a certain role in thermal conductivity, helping to maintain the uniformity of reaction temperature and improve mass transfer rate, thereby promoting reaction progress.

So when choosing ceramic balls with specific aluminum content, the process conditions of the reactor, operating temperature, and chemical environment used are usually considered.

Jiangxi OIM Chemical manufacture ceramic balls with different Al2O3, which is widely used in oil and petrochemical field. Welcome to check with us for any engineering consult.