Air separation desiccant Molecular sieve 13X APG and WS type silica alumina gel

2022-06-01

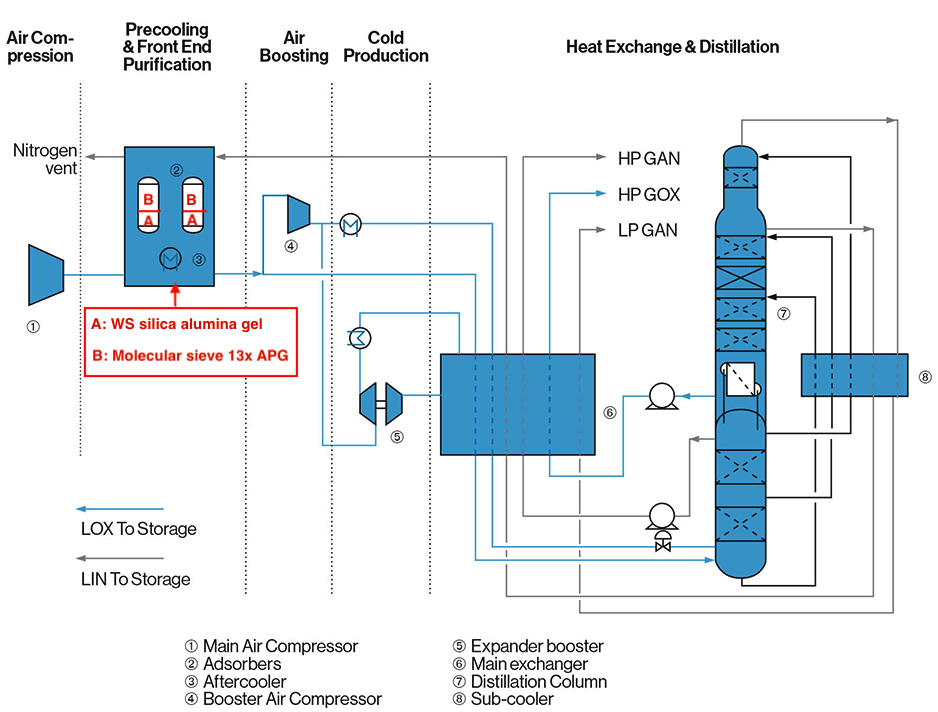

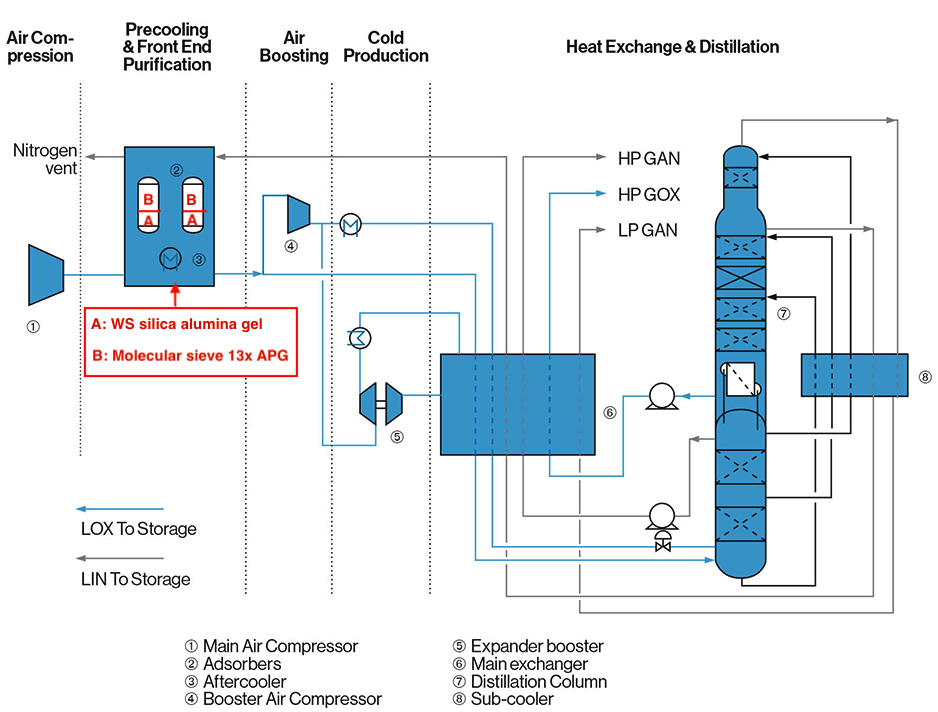

Presumably everyone is relatively unfamiliar with Air Separation. Actually, it is just a set of industrial equipment used to separate components in the air to produce oxygen, nitrogen and argon. Of course, there are many rare gases and so on. Air separation equipment uses air as raw material, and processes various gases through a complete set of system processes. It is widely used in metallurgy, coal chemical industry, large-scale nitrogen fertilizer, professional gas supply and other fields.

The air contains a small amount of water vapor, carbon dioxide, acetylene and hydrocarbons and a little dust and other impurities. If these impurities are allowed to enter the air separation unit, it will be very dangerous. The solid impurities will wear out the components, especially threatening the safe operation of high-speed rotating equipment. If they are brought into the heat exchanger, they will also contaminate the heat transfer surface and reduce the heat transfer effect; water vapor and Under low temperature conditions, CO2 will freeze and precipitate successively, thereby blocking the gas channel and the sieve holes of the tray; Acetylene and hydrocarbons accumulate in excess in the rectification tower, which is easy to cause explosion. Therefore, in order to improve the safety, reliability and economy of the device operation, the air must be purified.

Today we will focus on the Purification System in the air separation plant equipment.

There are three types of adsorbers used in the purification system: Vertical axial flow, Horizontal double bed and Vertical radial flow.

1) Vertical axial flow is mainly used for supporting air separation equipment below grade 10,000 (diameter has reached 4.6m).

2) The horizontal double bed is mainly used for the large and medium-sized air separation equipment. The bed is 1150mm molecular sieve 13x APG and 350mm WS type silica alumina gel. The screen of the 2 adsorbents must be intact. Avoid mixing together, causing adsorbent powder or molecular sieve poisoning.

* The molecular sieve purification process is that before the compressed air enters the cold box, it first passes through the molecular sieve purifier to remove moisture, carbon dioxide and other impurities in the air, and there will be no precipitation and freezing of these impurities in the air during the cooling process, which can ensure the air separation unit. normal work. This kind of work is achieved by using the ability of temperature and pressure swing to affect adsorption and desorption. The two adsorbents belong to a kind of physical adsorption and do not undergo chemical reactions.

* Air purification adopts double molecular sieve adsorbers bed, which are equipped with WS type silica alumina gel and molecular sieve 13x APG .

-- The function of silica alumina gel is to absorb moisture in the air. Silica alumina gel has a large adsorption capacity for air water content, but with the decrease of air water content, the adsorption capacity decreases. The analysis temperature is low, which is conducive to energy saving. And it can adsorb acid gases, never protecting molecular sieves.

-- The role of molecular sieves is to adsorb CO2 and hydrocarbons in the air. The order of adsorbed molecules is generally H20>C2H2>CO2.

Adsorbent is the basis of pressure swing adsorption technology. The performance of adsorbent determines the effect of adsorption and separation, which determines the investment of adsorption equipment and the economy of separation. Molecular sieves have a long life. Under normal operating conditions, the shelf time be used for at least 5 to 8 years without environmental pollution.

3) The vertical radial flow adsorber can effectively utilize the inner space of the container, so that the area of the adsorption layer with the same diameter is expanded by about 1.5 times, which can effectively reduce the height of the tower, and at the same time, the vertical installation occupies a small area. Due to the uniform airflow distribution, unlike the uneven airflow of the horizontal adsorber, the molecular sieve consumption is reduced by 20%, and the regeneration energy consumption is also reduced by 20%. However, the disadvantage of vertical radial flow is that the airflow is concentrated in the center (sector), which makes it faster than the horizontal penetration time (requires CO2<0.5ppm). The bed thickness is 1000mm+200mm, and the vertical radial flow can meet the configuration of the air separation plant above 20,000 grades.

Molecular sieve

type |

Pore diameter

(nm) |

Absorbing molecular |

|

3A |

0.3 |

H2O, NH2 |

|

4A |

0.4 |

C2H4,C2H6,SO2,CO2,H2S,C2H5OH |

|

5A |

0.5 |

C2H9~C22H46, n-C4H10,n-C4H9OH |

|

13X |

1.0 |

All molecular below 1.0nm |

|

13X APG |

1.0 |

All molecular below 1.0nm |

So what is the working principle of the molecular sieve 13x APG and silica alumina gel produced by OIM Chemical?

The working principle of air separation molecular sieve is very simple. In fact, it is the process of adsorption and regeneration, which realizes continuous operation. Alternately purify and regenerate using 2 purifiers. First, place the silica alumina gel at the bottom of the tower to absorb a large amount of moisture in the air. The molecular sieve 13x APG is activated with hot air or nitrogen. The activated molecular sieve has adsorption capacity. When it is close to saturation, it is transferred to the regeneration stage. First,

the pressure is equalized to recover part of the air, and then vented to normal pressure and heated with the purified gas. Then pass through the bed in reverse direction to regenerate the molecular sieve. After the bed reaches the temperature required for regeneration, it is transferred to cold blowing to cool down, and the whole regeneration process is completed, and then it enters the adsorption stage. The whole operation process of "adsorption - switching - regeneration (including cold blowing) - switching - adsorption" all runs according to the preset program.

OIM Chemical manufacture various types of adsorbents such as molecular sieve, silica gel, activated alumina, etc. If you have any technical questions, please feel free to consult.