Adsorbents for compressed air dryer

2021-11-07

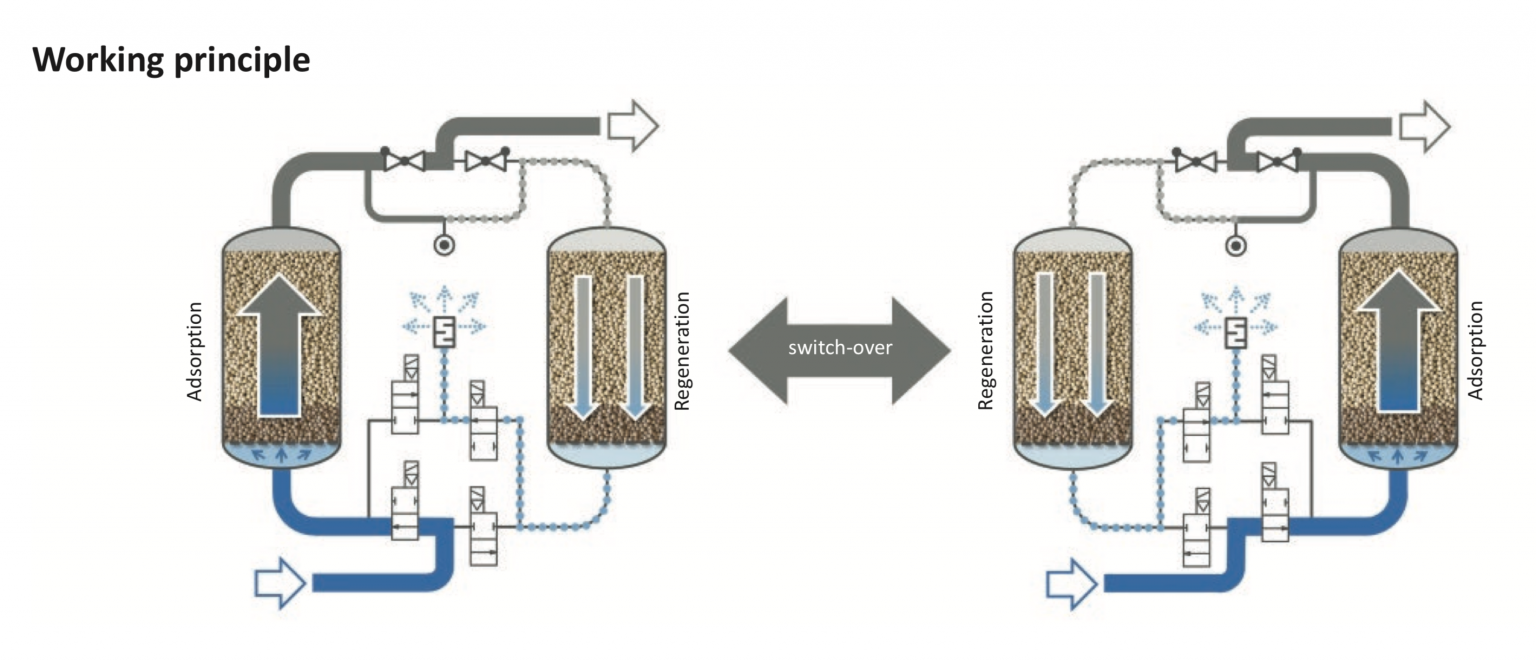

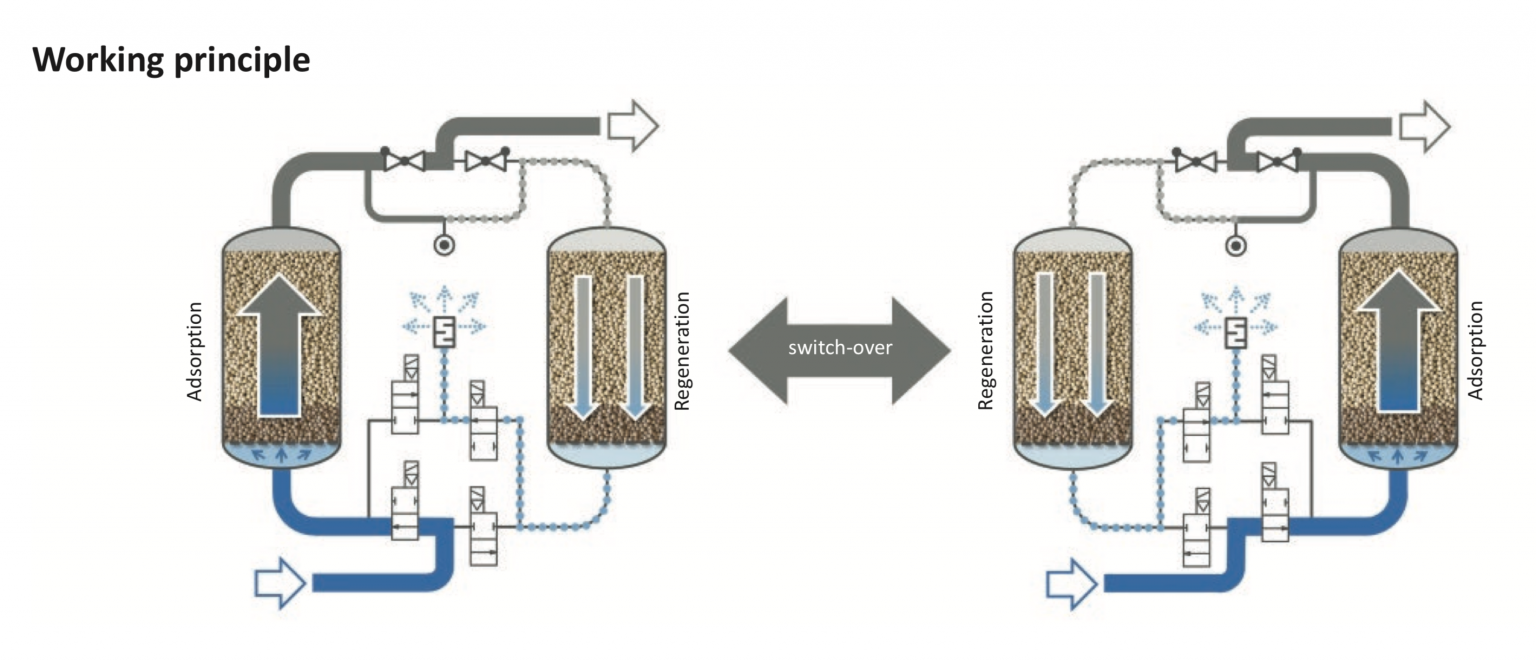

Compressed air dryers are widely used in the industry. When the pressure dew point temperature of the compressed air is required to be below 0 degrees, a compressed dryer should be used. The common adsorbents request are molecular sieves or activated alumina.

Now, we will briefly introduce these two adsorbents.

Activated alumina: has a strong adsorption capacity for water vapor, the water adsorption can reach 17-19%. It is a kind of high-strength adsorption material, and is currently the often used adsorbent in domestic adsorption dryers, and can withstand the high pressure impact of compressed air without pulverizing. Especially in the case of heatless regeneration, activated alumina is almost the best choice for obtaining compressed air with a pressure dew point below -40 degrees. The disadvantage is that deep drying is not possible, and the adsorption capacity of this adsorbent in a low-moisture environment is far inferior to molecular sieve. If the pressure dew point of -40°C ~ -70°C, it is difficult to achieve it just using activated alumina.

Molecular sieve: When compressed air (pressure dew point is lower than -60°C), generally use 4A molecular sieve (dew point is about -70°C) or 13x molecular sieve (dew point can reach -120°C). The adsorption capacity is 3 times than activated alumina and is an adsorbent that can be used for deep drying of compressed air. The disadvantage is that the strength is low, and it is easy to pulverize under the impact of high-strength compressed air. Therefore, the combination of activated alumina and molecular sieve for gas purification has a better effect.