Classification and function of ceramic balls

2021-06-25

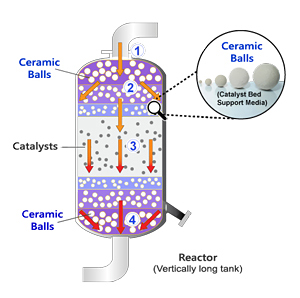

Ceramic ball is a large amount of support media in the chemical industry.

Now let me introduce this product to all of you:

The industrial ceramic balls can be divided into Packing ceramic balls and Grinding ceramic balls.

1. The packing ceramic ball is called “ Inert ceramic balls”. It has high strength, long shelf time and good chemical stability, will not chemically react with substances. High temperature and high pressure resistance, strong acid and alkali corrosion resistance, thermal shock. It contains 17% , 23-26% ceramic balls, middle ceramic balls, high alumina ceramic balls, 99% ceramic balls, open-pored ceramic balls, microporous ceramic balls, refractory balls etc. They are mainly used to increase the spread of gas or liquid, support and protect chemical materials with low strength. It is mainly used in the high temperature, high pressure, and extremely strong environment of the chemical industry, in the conversion of petroleum and chemical industries, in the reaction furnace, and in the melting tower to prevent the formation or deposition of the filter screen or damage the carrier of the fertilizer plant. It is also commonly used in reformers, reformers, hydrotransformers, desulfurization tanks and heating furnace reformers.

2. Grinding ceramic balls are divided into silicon carbide grinding ceramic balls, microcrystalline medium-aluminum grinding ceramic balls, and high-aluminum grinding balls. Generally 60%-65% Al2O3 is classified as medium aluminum balls, 75%-80% Al2O3 is medium-high aluminum balls, and over 90% Al2O3 is high-aluminum balls. Among them, the high-alumina balls are 90%, 92%, 95% and 99%. Due to its extreme high production cost, 99% is rarely manufactured by large manufacturers. At present, it is mainly made by hand and used in some special ceramic factories.