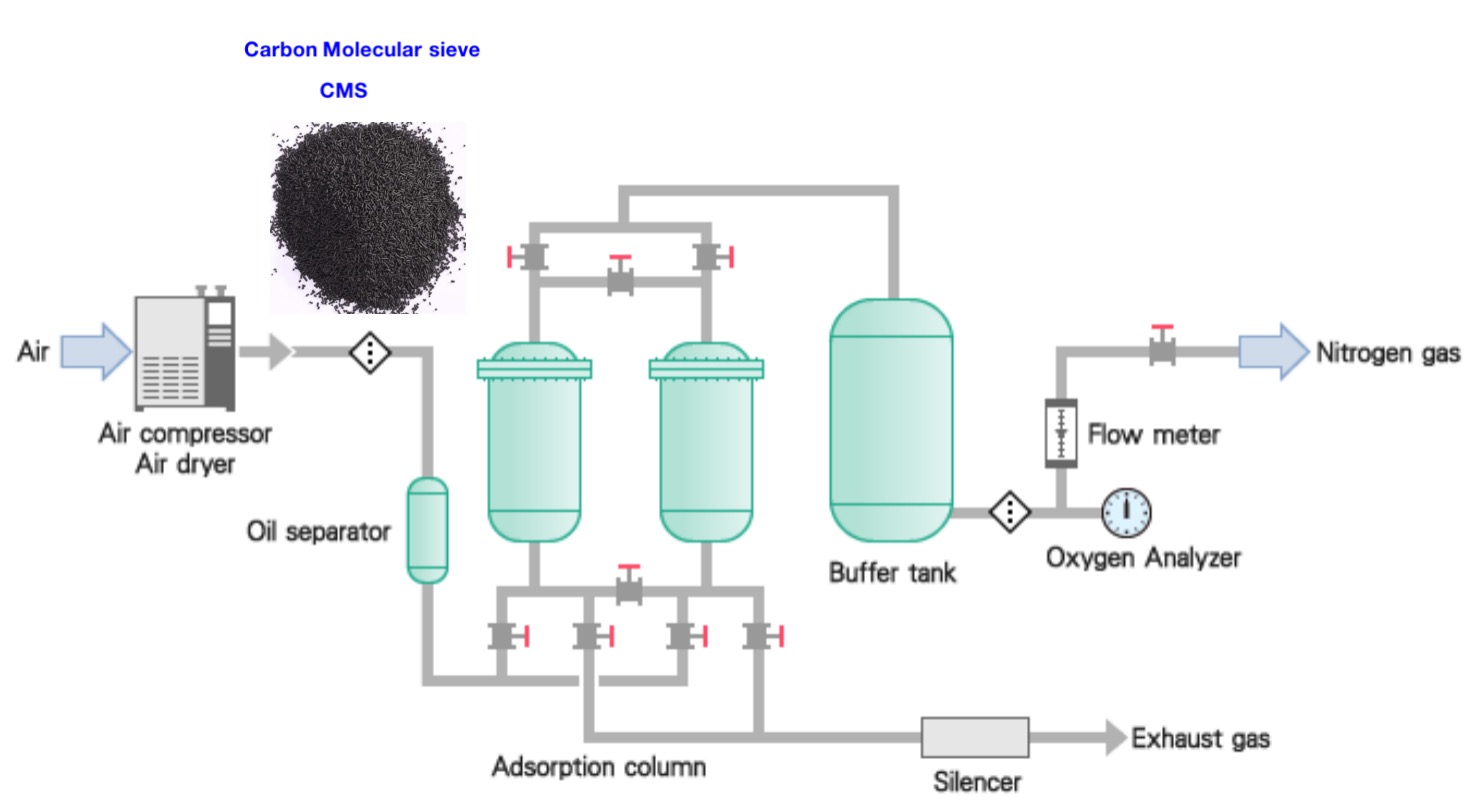

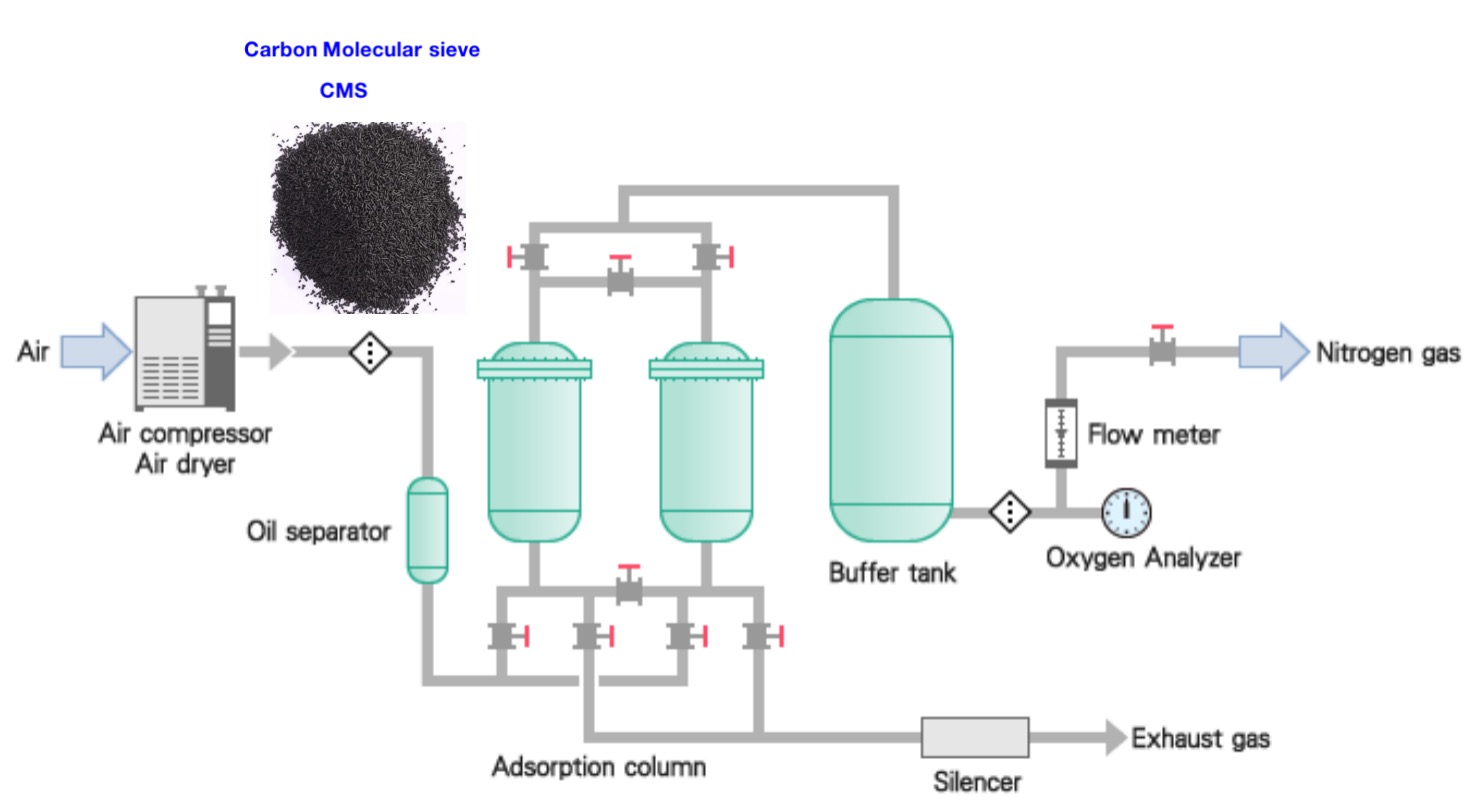

Working process for Carbon Molecular Sieve

2021-07-11

Carbon molecular sieve nitrogen production equipment (CMS-PSA) is a gas separation equipment, that uses carbon molecular sieve as adsorbent, air as raw material, and uses the principle of pressure swing adsorption principle to separate oxygen and nitrogen to produce high-purity nitrogen.

Carbon molecular sieve is a high-efficiency non-polar adsorbent with micropores on the surface that is processed by coal as the main raw material and processed through the processes of selection, crushing, molding, drying, activation, and heat treatment. It has different adsorption capabilities for gas molecules of different molecular weights, and the diffusion speeds of gas molecules of different dynamic diameters adsorbed in the micropores of the carbon molecular sieve are different: oxygen is 3.5 angstroms and nitrogen is 3.7 angstroms. However, the diffusion speed of oxygen molecules is hundreds of times faster than that of nitrogen molecules. This is because the smaller the molecule, the faster the diffusion rate. In a short period of time, because the diffusion rate of oxygen molecules is much faster than that of nitrogen molecules, oxygen molecules preferentially occupy the adsorption center of molecular sieve and are adsorbed in a large amount. After a few minutes, their adsorption capacity reaches more than 90%, which is almost close to equilibrium. The adsorption capacity is only about 5%. Taking advantage of the large difference in the adsorption of oxygen and nitrogen in a short period of time, fast switching between two identical adsorption towers, combined with the pressure swing adsorption process of pressurized oxygen adsorption and decompression oxygen desorption, separates oxygen from the air come out. Finally, the oxygen-containing waste gas is discharged from the bottom of the tower, and the nitrogen is retained in the nitrogen tank due to very little adsorption.