Activated Alumina vs Silica Gel

2022-07-07

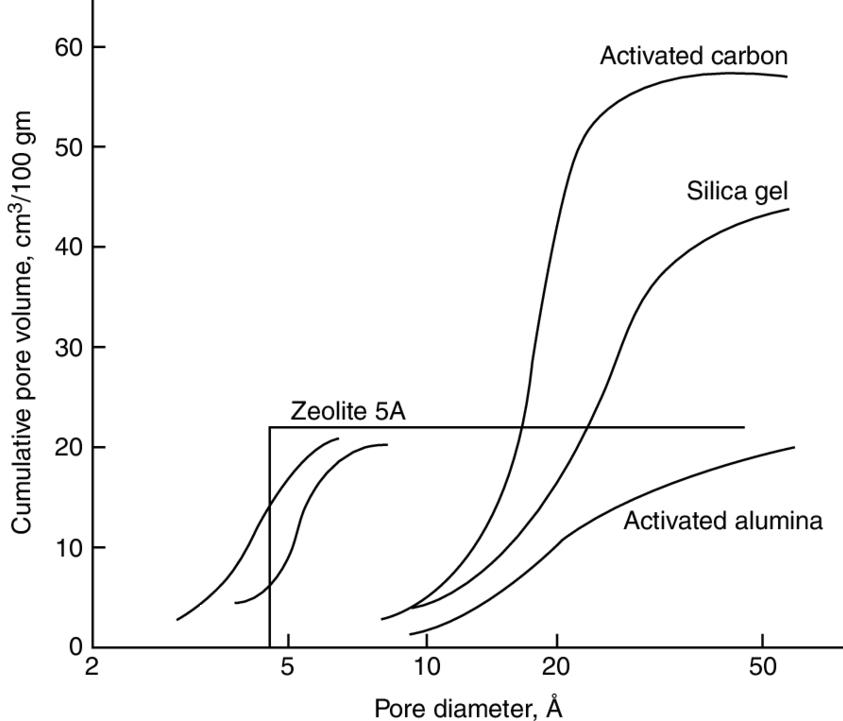

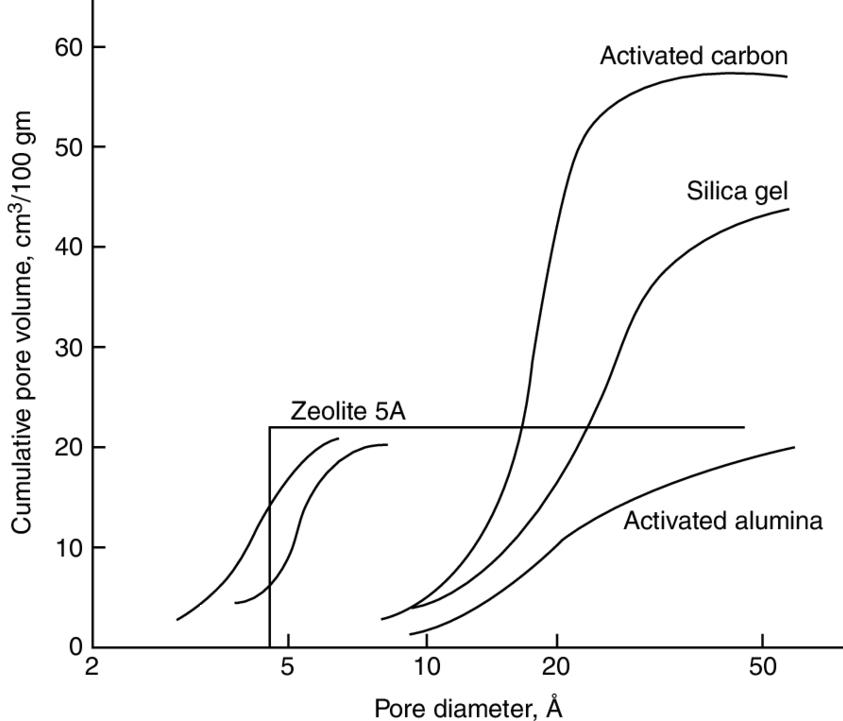

At present, the common used natural gas desiccants are activated alumina, silica gel and molecular sieves.

In the table below, we provide the physical properties of the relevant desiccants.

|

Desiccant |

Silica gel |

Activated alumina(F-200) |

H type

silica gel |

Molecular sieve

(Zeochem) |

|

Pore diameter (10-1nm) |

10~90 |

15 |

20~25 |

3,4,5,10 |

|

Bulk density(kg/m3) |

720 |

700~770 |

640~785 |

690~750 |

|

Specific heat capacity (kJ/kg.K) |

0.921 |

1.005 |

1.047 |

0.963 |

|

Dew point (℃) |

-50~-96 |

-50~-96 |

-50~-96 |

-70~-185 |

|

Adsorption capacity (%) |

4~20 |

11~15 |

12~15 |

8~16 |

|

Regeneration temperature (℃) |

150~260 |

175~260 |

150~230 |

220~290 |

|

Heat of adsorption(kJ/kg) |

2980 |

2890 |

2790 |

4190 (max) |

Silica gel desiccant has poor moisture absorption capacity and is more expensive. Activated alumina has strong moisture absorption capacity and is economic.

* Activated alumina is a polar adsorbent, mainly partially hydrated and porous alumina, and contains a small amount of other chemical elements, and its specific surface can reach more than 250m2/g. For example, the composition of F200 activated alumina is: Al2O3 94%, H2O 5.5%, Na2O 0.3% and F2O3 0.02%.

Because of its large wet capacity, activated alumina is often used for dehydration of gases with high water content. In addition, because the pore size of activated alumina is not uniform and has no obvious adsorption selectivity, it can also adsorb heavy hydrocarbons during dehydration and is not easy to remove during regeneration. Usually, the gas dew point of activated alumina after drying can reach -70 degrees.

* Silica gel is a polar adsorbent. When it adsorbs water vapor in the gas, its amount can reach 50% of its own mass. Even in the air flow with a relative humidity of 60%, the wet capacity of microporous silica gel can reach 50%. 24%, so it is often used for gas dehydration with high water content. When silica gel absorbs moisture, it will release a lot of adsorption heat, which is easy to break and generate dust. In addition, its micropore size is also extremely non-uniform, and there is no obvious adsorption selectivity. The gas dew point after drying with silica gel can reach -60 degrees.

We have a customer who purchased 2 kinds of our adsorbents for waste gas treatment,

the main differences are as below:

*Activated alumina adsorbent

Activated alumina generally refers to a porous structure adsorbent formed by heating and dehydration of alumina hydrate. It is a polar adsorbent, non-toxic, stable to most gases and vapors, and will not break when immersed in water, and has high mechanical strength. The specific surface area of activated alumina is about 250-350m2/g, and it can be recycled and used with little change in physical and chemical properties. Due to the large adsorption capacity of activated alumina for water, it is often used for dehumidification and drying of high-temperature gas, and can also be used for desulfurization of petroleum gas and as a defluoride agent for high-fluoride drinking water.

*Silica gel adsorbent

Silica gel is a kind of silicic acid polymer particles, which is made of sodium silicate and sulfuric acid or hydrochloric acid by gelation, washing, drying and baking. Silica gel is a polar adsorbent that absorbs water, and it is difficult to adsorb non-polar organic substances. When silica gel adsorbs moisture in gas, it can reach 50-60 of its own weight. Its adsorption heat is very large, and it can release a lot of heat when absorbing moisture, making the silica gel easily broken. In industry, silica gel is mostly used for drying high temperature gas and recovering extremely useful hydrocarbon gas from waste gas, and can also be used as catalyst carrier.

How to choose a suitable adsorbent: Generally, silica gel is suitable for the separation of acidic substances, and activated alumina is used for the separation of alkaline substances.

In addition, when the relative humidity is generally high, water resistant silica gel is used for pre-drying; when the relative humidity is low, molecular sieve adsorption is used. If the requirements for drying and humidity are high, and the gas humidity is high, it is recommended to use activated alumina or water-resistant silica gel to dry the first layer, and then use molecular sieve for further adsorption, so as to give full play to the molecular sieve, activated alumina and water-resistant silica gel. Features, to achieve the best drying and adsorption effect.

Because the adsorption rate of molecular sieve for polar molecules such as water is much higher than that of silica gel and activated alumina when the partial pressure or concentration is very low. Although the equilibrium water absorption of activated alumina and water resistant silica gel is higher than that of molecular sieve when the relative humidity is high, with the increase of the linear velocity of the adsorbate, the water absorption rate of water-resistant silica gel is less and less efficient than that of molecular sieve.

We hope the above information can help our customers to choose suitable adsorbents. If need to know more about adsorbents, please feel free to contact us.