Technical article

2023-08-20

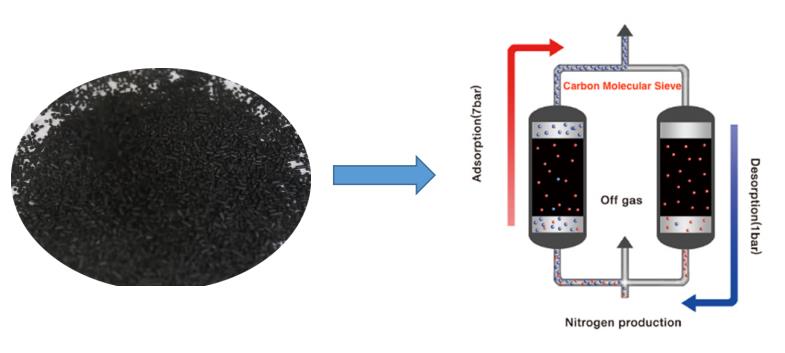

Carbon molecular sieves (CMS) play a vital role in the operation of Pressure Swing Adsorption (PSA) nitrogen generators. CMS are highly selective adsorbents that allow the separation of various gases based on their molecular size and polarity. In the context of PSA nitrogen generators, CMS is used to remove oxygen and other trace contaminants from the air, thus generating high-purity nitrogen gas. Let's dive into the specific application of carbon molecular sieves in PSA nitrogen generators!

Carbon molecular sieves (CMS) play a crucial role in the Pressure Swing Adsorption (PSA) technology used in nitrogen generators. These sieves are highly efficient at separating nitrogen gas from other gases in the air, making them essential in various industries.

CMS function by utilizing their unique porous structure, which allows for the adsorption of oxygen, moisture, and other impurities while allowing nitrogen molecules to pass through. This separation process occurs when air is passed through a bed of CMS under high pressure. The nitrogen-enriched gas that emerges on the other side can then be collected and used for a wide range of applications.

One of the primary applications of PSA nitrogen generators is in industries where a consistent and reliable source of high-purity nitrogen is required. For example, in the food and beverage industry, nitrogen is used for food packaging, preservation, and dispensing systems. The controlled environment created by nitrogen helps extend the shelf life of products and maintains their freshness.

In the pharmaceutical industry, PSA nitrogen generators are utilized to achieve precise nitrogen gas requirements in various processes, such as inerting, purging, and blanketing. The use of nitrogen ensures product integrity and prevents contamination.

Other industries that benefit from PSA nitrogen generators include electronics manufacturing, chemical processing, oil and gas, and metal fabrication. In these industries, nitrogen is used for purposes like preventing oxidation, purging pipelines and storage tanks, and as a protective gas during welding operations.

The specific properties of carbon molecular sieves make them ideal for these applications. Their high adsorption selectivity for oxygen allows for the production of nitrogen with purity levels ranging from 95% to 99.999%. Additionally, CMS have excellent thermal stability, high mechanical strength, and resistance to contaminants, resulting in long service life and consistent performance.

With their widespread use and effectiveness in PSA nitrogen generators, carbon molecular sieves have become an integral part of industries requiring nitrogen gas. Their ability to produce high-purity nitrogen reliably and efficiently contributes to improved productivity, cost savings, and enhanced product quality.

OIM Chemical is professional suppliers in adsorbents series, molecular sieve, activated alumina, silica gel and ceramic balls. If you need more informaiton, just contact us via info@oimchem.com.