Application of Molecular Sieve 4A in Air Dryers

2023-08-11

Molecular sieve 4A, a type of crystalline aluminosilicate material, have gained significant recognition for their ability to adsorb moisture and other polar molecules from gases and liquids. This article explores the specific application of 4A molecular sieves in air dryers, highlighting their crucial role in maintaining dry and moisture-free air in various industrial processes.

Compressed Air Drying:

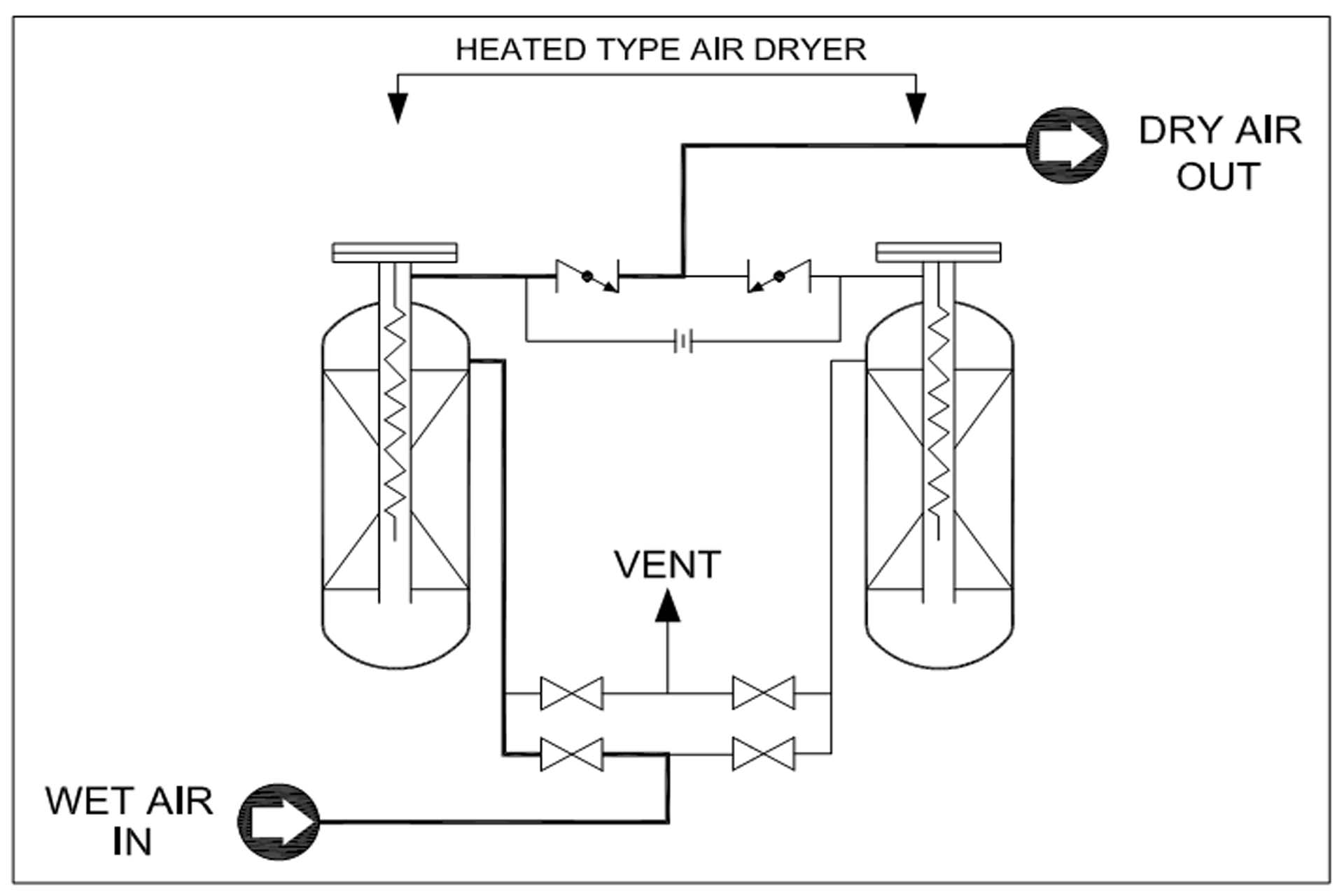

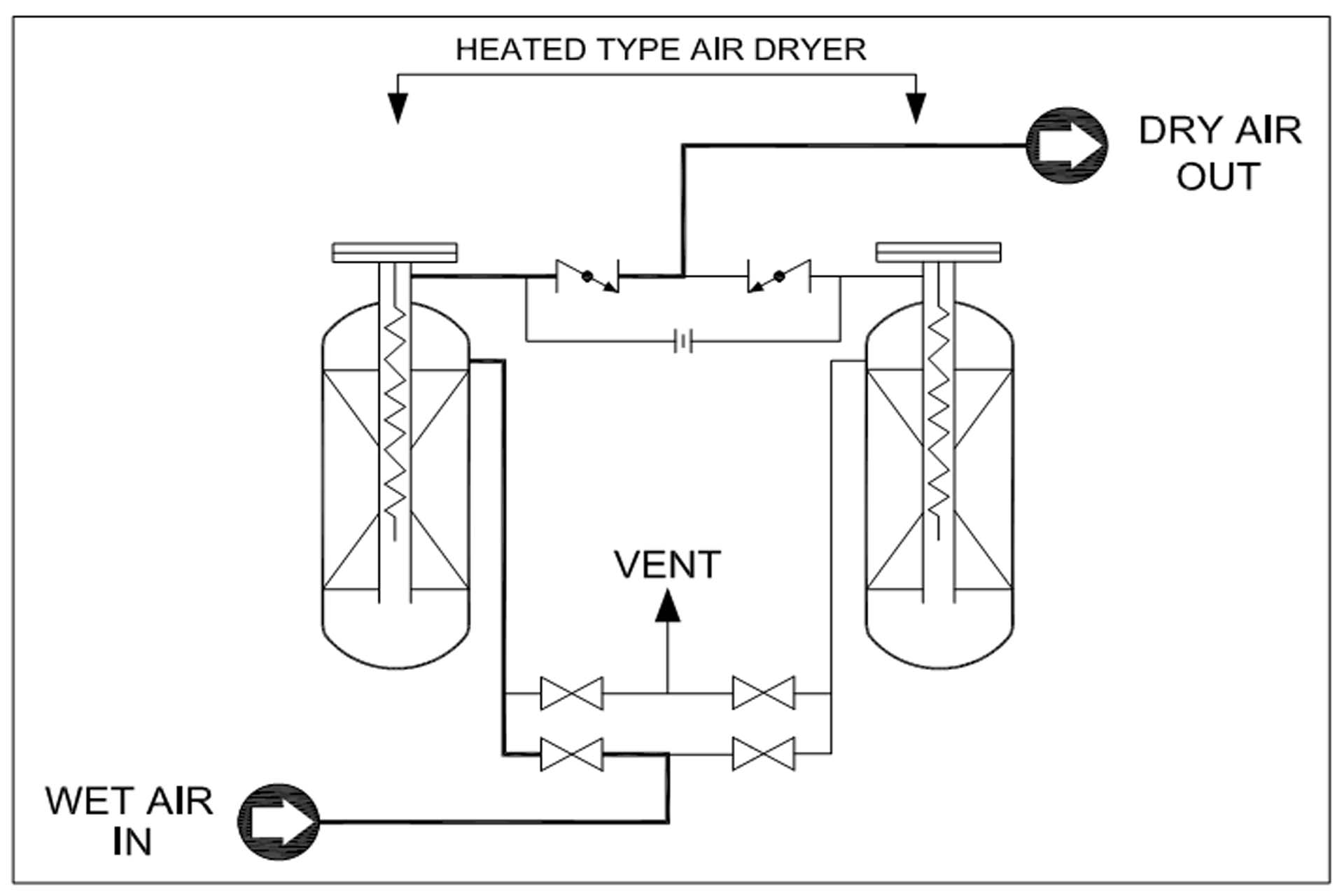

Air compressors often generate moisture-laden air due to the presence of water vapor. Moisture in compressed air can lead to corrosion, equipment malfunction, and compromised product quality. Molecular sieve 4A are employed in compressed air dryers to selectively adsorb water molecules, effectively reducing the dew point and ensuring that the compressed air remains dry and moisture-free. This application is essential in industries such as manufacturing, automotive, and electronics, where dry air is vital for process reliability and product integrity.

Instrumentation and Control Systems:

Sensitive instrumentation and control systems are susceptible to damage and inaccuracies caused by moisture. 4A molecular sieves play a critical role in protecting these systems by removing moisture from the air supply. In applications like laboratories, pharmaceutical production, and food processing, where precise measurements and control are essential, the use of 4A molecular sieves in air dryers ensures the reliability and accuracy of these systems.

Painting and Coating Processes:

Moisture in the air can adversely affect the quality and appearance of paint and coatings. In industries such as automotive painting, furniture manufacturing, and aerospace, maintaining a dry environment is crucial for achieving consistent and flawless finishes. 4A molecular sieves help prevent defects caused by moisture-related issues, ensuring that the painting and coating processes yield high-quality results.

Pneumatic Systems:

Pneumatic systems, which rely on the controlled use of compressed air, can experience reduced efficiency and increased wear due to moisture. 4A molecular sieves are integrated into air dryers in pneumatic systems to remove moisture, preventing corrosion and ensuring smooth operation. Industries such as automation, packaging, and material handling benefit from the enhanced performance and extended lifespan of pneumatic components achieved through the use of 4A molecular sieves.

Food and Beverage Industry:

In the food and beverage industry, maintaining dry air is essential to prevent spoilage, preserve flavor, and ensure product safety. 4A molecular sieves are employed in air dryers to remove moisture from the air used in food processing, packaging, and storage. By controlling humidity, 4A molecular sieves contribute to extending the shelf life of products and maintaining their quality.

The application of 4A molecular sieves in air dryers plays a vital role in various industries by effectively removing moisture and maintaining dry air. From ensuring the integrity of sensitive control systems to enhancing the quality of finished products, 4A molecular sieves contribute to improved efficiency, reliability, and overall performance. As industries continue to prioritize precision and quality, the use of 4A molecular sieves in air dryers remains a key solution for achieving moisture control and optimal operational outcomes.