Molecular sieve oxygen

2021-07-11

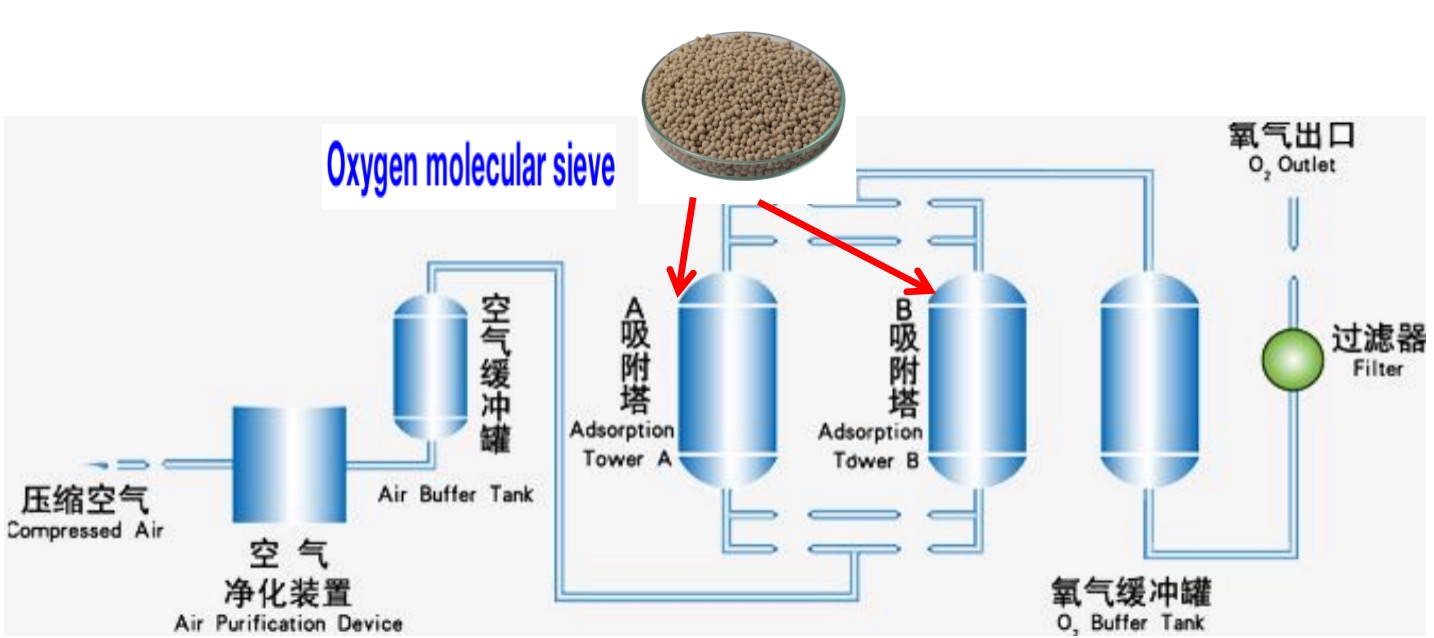

Molecular sieve oxygen production refers to the use of molecular sieve adsorption characteristics at room temperature to separate oxygen from the air. Generally, Pressure Swing Adsorption (also called “PSA”) separation technology is used and mainly physical adsorption.

PSA oxygen production can produce oxygen with a purity of 80%-95%. The power consumption of oxygen production is generally 0.32kWh/Nm3~0.37kWh/Nm3, and the adsorption pressure is higher than atmospheric pressure, generally 30kPa~100kPa.

Pressure swing adsorption uses the characteristics of a special adsorbent (usually use oxygen molecular sieve, Na+ type or lithium type molecular sieve of Jiangxi OIM Chemical Co., Ltd) under normal temperature and pressure conditions, and uses air as raw material to enter through the air compressor. Then enter into Purification devices to purify high-quality air. Then enter the adsorption tower. Under pressurized conditions, the oxygen-making molecular sieve preferentially adsorbs impurities such as N2, CO2 and H2O in the air, so as to obtain higher purity O2; under reduced pressure conditions, the N2 in the adsorbent are desorbed. For other impurities, the adsorbent is regenerated. Generally, 2 towers (or multiple towers) work cyclically, so as to realize the adsorption-desorption cycle operation, realize continuous oxygen supply, and continuously produce oxygen with a purity of 90-95%.