How to choose adsorbent in adsorption air dryers

2022-01-17

Name: Adsorption dryer (Heatless regenerated and heat regenerated adsorption dryer);

Key words: Adsorbent -- activated alumina or molecular sieve to adsorb moisture;

Function: Reduce the moisture content in the compressed air, so that the dew point of the outlet gas can reach -40 degrees or more.

Recently we have received a lot of inquiries, most of them want to replace the adsorbent in the dryer. But many customers do not know which adsorbents to choose. Hope below content can help solve your problems.

As the main body of the dryers, the adsorbent is subjected to frequent shocks of pressure, water vapor and heat most of the time, so it needs to be replaced regularly. After activated alumina instead of silica gel as the main adsorbent, various performance indicators were greatly improved. Its compressive strength and water adsorption performance have reached a very high level. As long as there are no operating factors such as "insufficient regeneration energy consumption", after use the activated alumina ball, the dew point of the compressed air can reach -40 degrees stably, and its working time can reach at least 2-3 years.

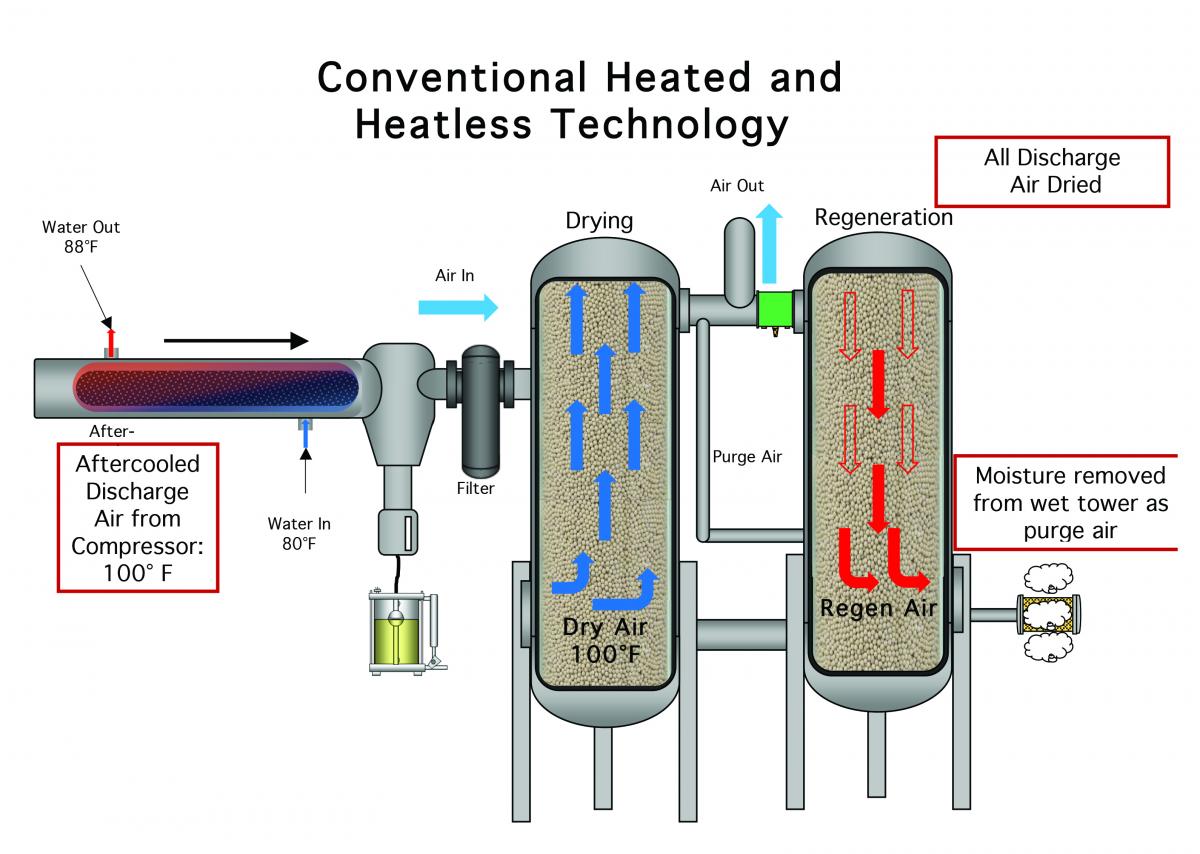

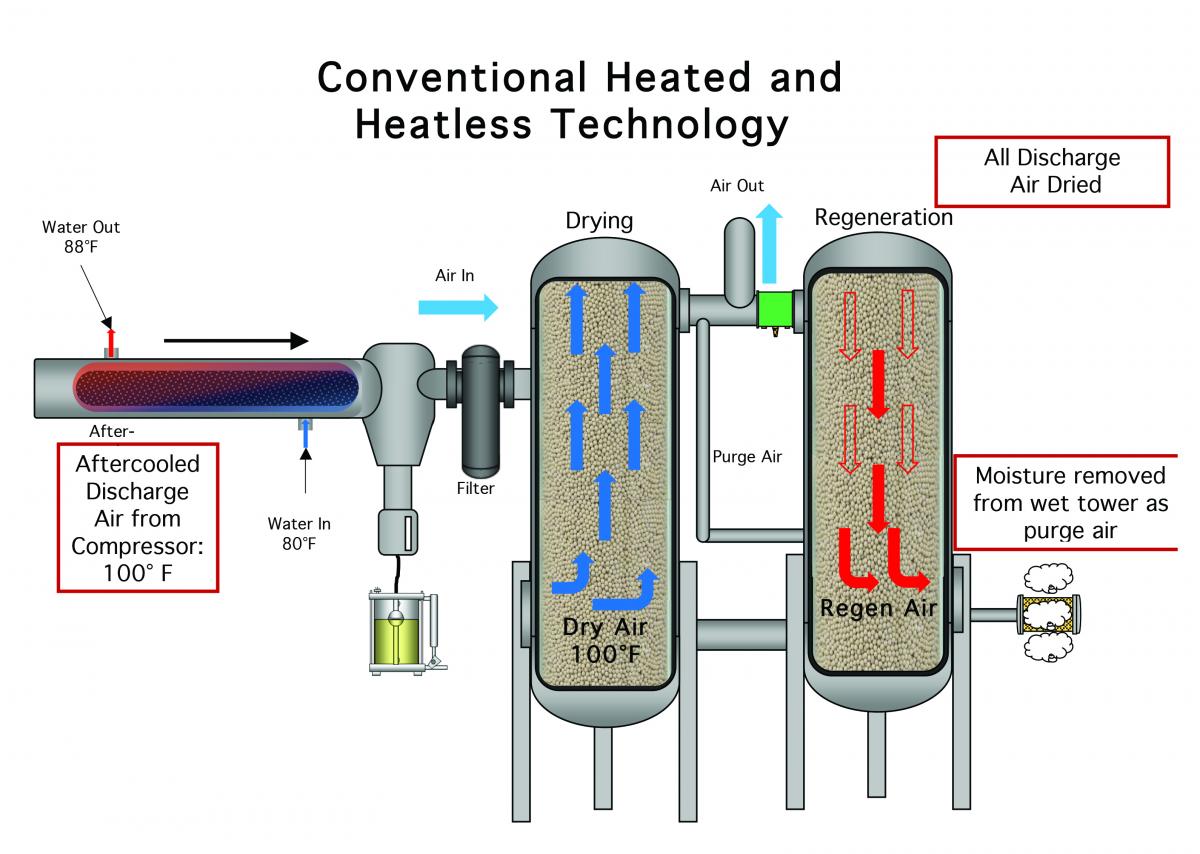

Adsorption dryers are mainly divided into two types: Heatless regenerated adsorption dryers and heat regenerated adsorption dryers according to the regeneration method of adsorbents. Since the heatless regenerated adsorption dryer works according to Isothermal Adsorption, it is also called "Pressure Swing Adsorption"; the thermal heat regenerated adsorption dryer works according to Isobaric Adsorption, also known as "Temperature Swing Adsorption".

So what's the difference between them? We have listed 4 main points below. If you have any additions, please feel free to discuss:

1. Difference in adsorption cycle: the regeneration depth of heatless regeneration is low, and the dynamic adsorption capacity of the adsorbent is low, so the adsorption capacity of the unit adsorbent is small, thus the filling quantity of the adsorbent cannot be effectively dried for a long time, and the regeneration must be switched in time. Therefore, in the adsorption cycle setting time is shorter, and it can generally be adjusted within 4 to 15 minutes;

2. Adsorbent quantity: the low depth of athermal regeneration will affect the adsorption capacity, the filling quantity of the adsorbent will increase, and the replacement frequency will be higher than that of heat regeneration;

3. Regeneration gas consumption: the gas consumption of heatless regeneration is larger, generally about 13-20%; while the gas consumption of heat regeneration is 6-10%;

4. Drying effect: Generally speaking, it is difficult to achieve deep regeneration without heat regeneration. The pressure dew point value is generally -20 to -40 ℃; while thermal regeneration can achieve deep water removal with pressure dew point of -70 ℃ .

Of course, the choice of adsorbent also mainly depends on the settings of the dryer. If the set pressure dew point is -40 degrees or below, choosing activated alumina can save costs better; and if the pressure dew point is -70 degrees, 4A molecular sieve will make up for the lack of activated alumina, so as to achieve deep drying.