Technical article

2021-11-10

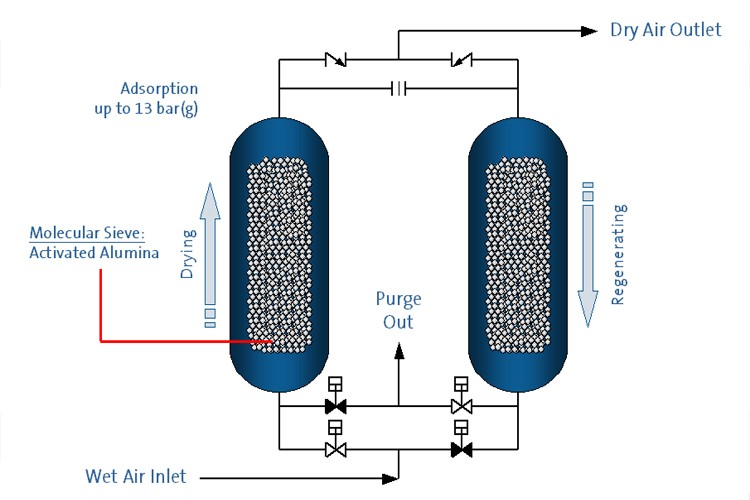

Molecular sieve is a kind of alumino silicate, which is mainly composed of silicon and aluminum connected by oxygen bridges to form an empty framework structure. In the structure, there are many pores with uniform pore size and cavities with neat arrangement and large internal surface area. In addition, it also contains metal ions with a lower electricity price and a larger ion radius and water in a combined state. Because water molecules are continuously lost after heating, but the structure of the crystal skeleton remains unchanged, many cavities of the same size are formed, and the cavities are connected by many pores with the same diameter. Substance molecules smaller than the diameter of the pores are adsorbed inside the cavity. , And exclude molecules larger than the pores, so that molecules of different sizes and shapes are separated until the role of sieving molecules, so it is called molecular sieves. It is mainly used for deep drying of various gases and liquids, separation and purification of gases and liquids, catalyst carriers, etc., so it is widely used in oil refining, petrochemical industry, chemical industry, metallurgy, electronics, national defense industry, etc., at the same time in medicine, light Industry, agriculture, environmental protection and many other aspects are also increasingly widely used.

In order to achieve good operating performance and the longest shelf time, the molecular sieve must be regenerated after a certain period of use. The molecular sieve after the correct regeneration is the same as the fresh one, and the degradation and aging of its adsorption performance and mechanical properties are very low.

There are two basic methods for molecular sieve regeneration:

1) Change the temperature, called "change temperature".

It removes the adsorbed substances by heating the molecular sieve. In industry, it is generally heated with preheated regeneration gas to sweep the molecular sieve to about 200 degree and take away the absorption substance that has been desorbed.

2)Change the relative pressure, called "variable pressure".

Generally used in gas phase adsorption process. The basic method is to keep the temperature of the adsorbent constant, and to remove the absorption substance by reducing the pressure and blowing back with inert gas.

Regeneration is usually carried out in the reverse direction of adsorption, which makes most of the substance contained at the entrance of the adsorption bed need not pass through the entire bed, and part of the molecular sieve does not come in contact with the hot and humid gas, thereby increasing the shelf life of the molecular sieve. The regeneration gas should be as dry as possible, otherwise it will affect the adsorption efficiency.