Hydrogen peroxide production Activated Alumina

2022-11-21

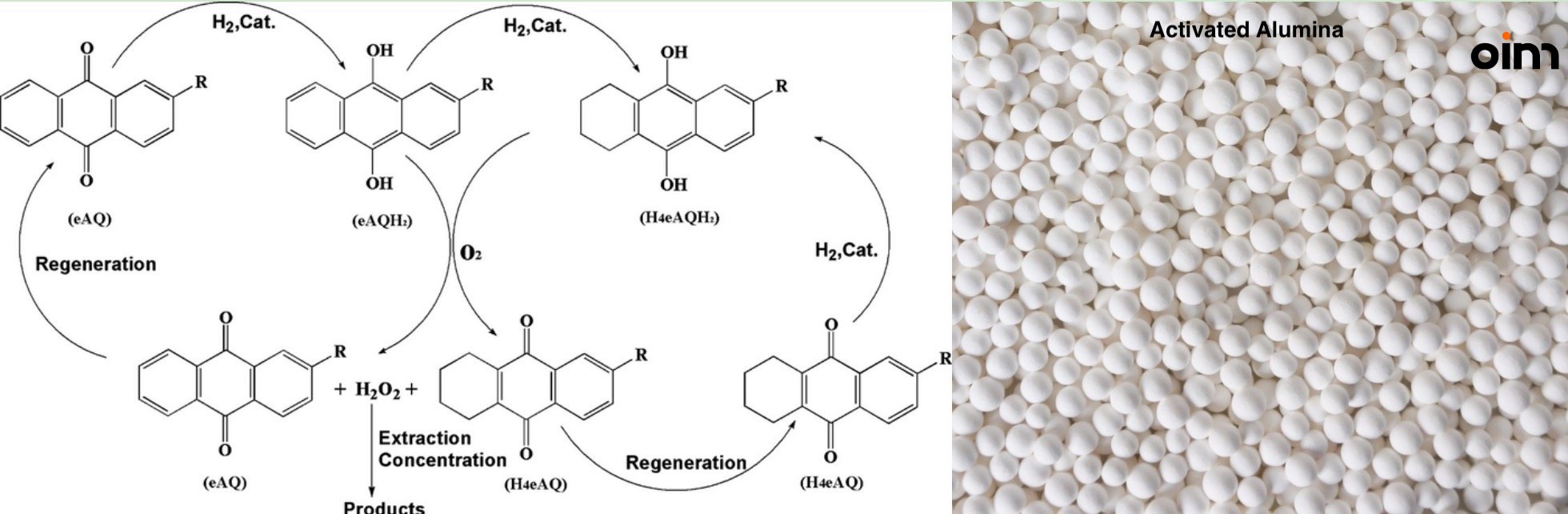

Hydrogen peroxide is an oxidant, which is widely used in bleaching, organic synthesis, electroplating, sewage treatment, cosmetics and other industries in paper making, textile and other industries. So, do you know the role of activated alumina in hydrogen peroxide production? The activated alumina plays two roles in the production of hydrogen peroxide. First, the activated alumina regenerates the degradation products generated in the hydrogenation and oxidation processes of the working solution, increases the effective anthraquinone content in the working solution, and stabilizes the composition of the working solution; Second, a small amount of lye entrained in the working solution in the post-treatment process of activated alumina adsorption to avoid poisoning of palladium catalyst and oxidation caused by high alkalinity in the working solution, as well as hydrogen peroxide decomposition in the extraction process.

Today, we will specifically talk about activated alumina for hydrogen peroxide production. In the production of hydrogen peroxide, our activated alumina is used in the following steps.

1. Filter impurities

The activated alumina filler layer of the clay bed can play a certain role in filtering the working solution. However, after the activated alumina has been used for a long time, there are a large amount of irreversible degradation products, catalyst powder alumina sludge and other impurities accumulated in the activated alumina at the bottom of the clay bed. Therefore, before replacing the activated alumina, the working fluid in the clay bed cannot be directly pressed into the system. It must be pumped into the configured axe kettle for cleaning before recycling, so as to prevent the entire system from being polluted.

2. Purified hydrogen peroxide

After washing away the alkali on the surface of activated alumina with pure water and treating it with 0.5% - 5% nitric acid solution, alumina can be used to purify the hydrogen peroxide residue in the concentration process. The effect is very ideal. It is a way to save energy, reduce consumption and increase output.

3. Replacement of activated alumina

When the effective anthraquinone content of the working solution is basically unchanged after passing through the activated alumina, in order to maintain the stability of the working solution components, the amount of anthraquinone added to the system increases significantly, indicating that its ability to regenerate degradation products decreases, and the activated alumina should be replaced. Generally, two clay beds are connected in parallel. When they are used for a certain period and all relevant indicators cannot meet the production requirements, the clay beds and activated alumina need to be replaced in a timely manner.

3.1 Treatment of invalid activated alumina

After the working fluid is withdrawn from the clay bed, a lot of working fluid is also adsorbed in the activated alumina micropores, which needs to be purged with steam from top to bottom. Generally, 1000kg activated alumina can adsorb about 400kg working solution. After the invalid activated alumina is dried, it is discharged from the clay bed. By observing the color change, crushing and caking, it can be judged whether there is bias current and whether there is serious alkali in the use process.

3.2 Loading of activated alumina

After the invalid activated alumina is unloaded, a lot of alumina powder is attached to the inner wall of the clay bed, the screen, and the ceramic ball, which are rinsed with pure water and dried before loading. If a large amount of activated alumina dust is used, it must be screened first to remove the dust. When filling, the stainless steel wire mesh and the clay bed wall shall be closely attached without leaving any gap, and shall be compacted with a porcelain ball. Otherwise, once a large amount of dust is brought into other processes by the working fluid, it will have a negative impact on the system. In addition, blind plates shall be added to the steam pipeline at the top of the clay bed before the clay bed is put into use to prevent the steam condensate from flowing into the activated alumina layer and affecting its activity.

Therefore, in the use of the special activated alumina for hydrogen peroxide, only when the basic properties and the use methods are strictly in accordance with the procedures, can we ensure the full play of the regeneration capacity of the activated alumina and ensure the efficient and stable operation of the device, which is very beneficial to reducing costs and optimizing operation.