Carbon molecular sieve working principle and instruction

2022-06-20

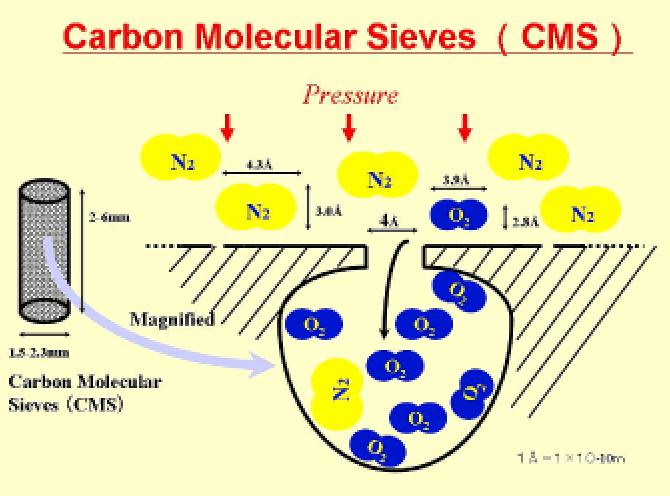

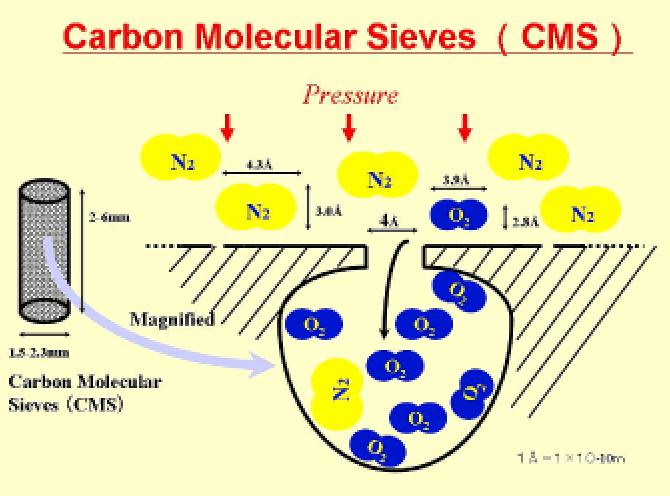

The working principle of carbon molecular sieve is to use the characteristics of carbon molecular pore sieving to separate oxygen and nitrogen, so as to obtain high-purity nitrogen. When carbon molecular sieve adsorbs impurity gas, the macropores and mesopores only function as channels, and the adsorbed molecules are transported into the micropores. The carbon molecular sieve side contains a large number of micropores, which enables molecules with small kinetic sizes to diffuse rapidly into the pores, while restricting the entry of large-diameter molecules. Due to the different interdiffusion rates of gas molecules of different sizes, the components of gas mixtures can be effectively separated. Therefore, in the production of carbon molecular sieves, the pore distribution inside should be 0.28-0.38 nm according to the molecular size. Within the pore size range, oxygen can quickly diffuse into the pores through the micropores, while nitrogen is difficult to pass through the micropores to achieve the separation of oxygen and nitrogen. The pore size of the pores is the basis for carbon molecular sieves to separate oxygen and nitrogen. If the pore size is too large, oxygen and nitrogen molecular sieves can easily enter the micropores and cannot be separated; when the pore size is too small, oxygen and nitrogen cannot enter.

Carbon molecular sieve is an important core part of PSA nitrogen generator to realize nitrogen and oxygen separation. Carbon molecular sieve is an adsorbent for extracting nitrogen from air. When the adsorption pressure is the same, the adsorption capacity of carbon molecular sieve for oxygen is greater than that for nitrogen.

1. Composition of carbon molecular sieve

The main component of carbon molecular sieve is elemental carbon, and the appearance is black columnar solid. Because it contains a large number of micropores with a diameter of 4 angstroms, the modified micropores have a strong instantaneous adsorption affinity for oxygen molecules, and can be used to separate oxygen and nitrogen in the air. Nitrogen is produced industrially using pressure swing adsorption devices. The carbon molecular sieve oxygen generator has a large amount of nitrogen, a high nitrogen recovery rate and a long service life. It is suitable for various types of pressure swing adsorption nitrogen generators and is the preferred adsorbent for pressure swing adsorption nitrogen generators.

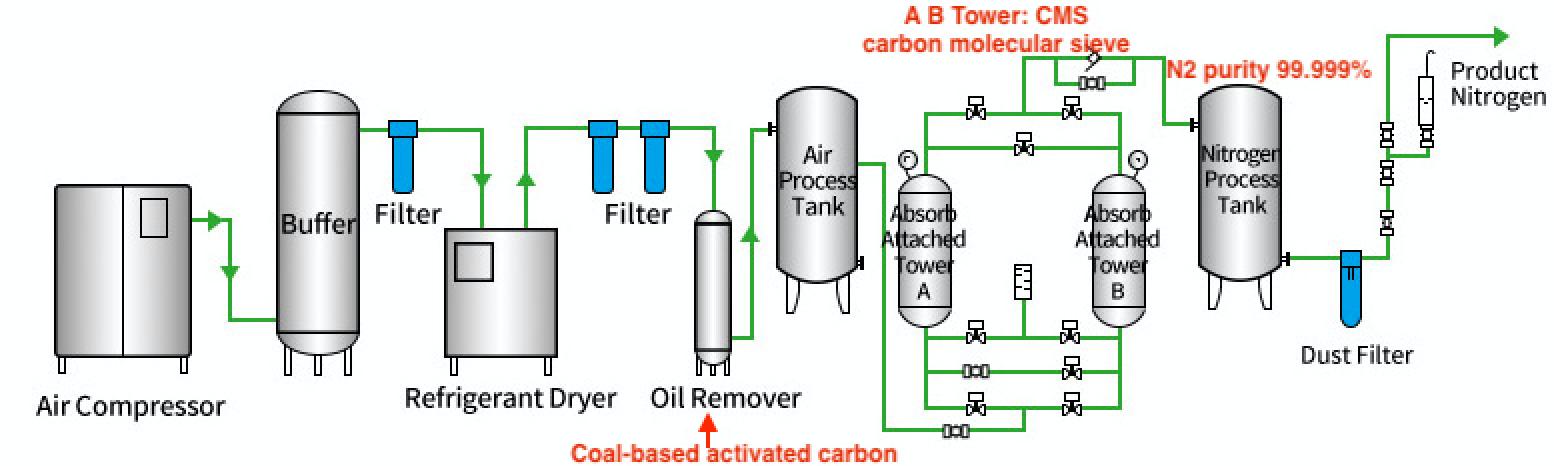

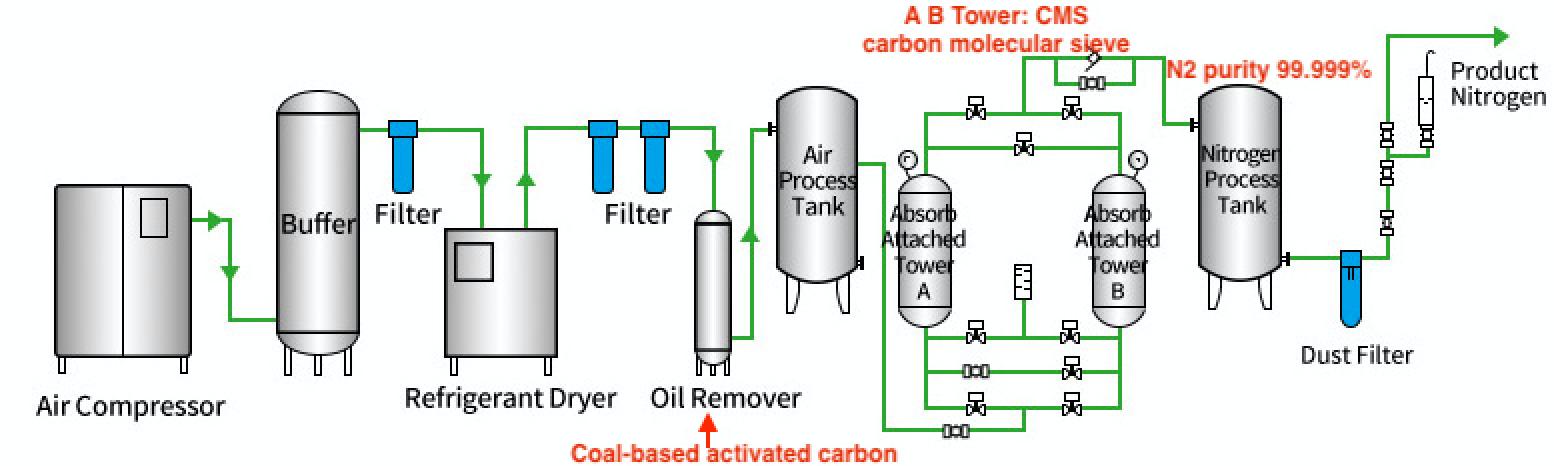

2. Carbon molecular sieve air separation nitrogen generator

This device is generally called PSA nitrogen generator, also known as a carbon molecular sieve nitrogen generator. The technological process adopts the pressure swing adsorption method at high temperature, and the pressure swing adsorption is an adsorption separation process without a heat source. The adsorption capacity of carbon molecular sieve to adsorbed oxygen molecules is due to adsorption during stamping and gas production, and desorption during depressurization and exhaust, so as to regenerate carbon molecular sieve. At the same time, the nitrogen gas enriched in the gas phase of the bed passes through the bed to become the finished nitrogen, and each step is a cyclic operation.

3. Conditions required for carbon molecular sieve to produce high-purity nitrogen

1). Air compression purification process

It is very necessary for the pure raw air to enter the carbon molecular sieve adsorption tower, because the particles and organic atmosphere entering the adsorption tower will block the micropores of the carbon molecular sieve and gradually reduce the separation performance of the carbon molecular sieve.

The methods of purifying the raw air are as follows:

* Keep the air inlet of the air compressor away from places with dust, oil mist and organic atmosphere. Usually, we recommend using activated carbon adsorbent to adsorb impurities and oil mist in the air.

* Through the cold dryer, adsorbent purification system, etc., the final treated raw air enters the carbon molecular sieve adsorption tower. Usually, we recommend using activated alumina adsorbent (dew point -40 degrees) to absorb excess moisture to achieve the highest purity air entering the PSA nitrogen generator.

2). Produce nitrogen concentration and gas production

When carbon molecular sieve is used to produce nitrogen, its N2 concentration and gas production can be adjusted arbitrarily according to the needs of users. When the gas production time and operating pressure are determined, if the gas production is reduced, the N2 concentration will increase, otherwise, the N2 concentration will decrease. Users can adjust according to actual needs.

3). Pressure equalization time

In the process of carbon molecular sieve nitrogen production, when the adsorption of one adsorption tower is completed, the pressurized gas in this adsorption tower can be injected into another regenerated adsorption tower from the upper and lower directions, and the gas pressure of the two towers can be made the same. The process is called the pressure equalization of the adsorption tower. By selecting the appropriate pressure equalization time, the energy can be recovered and the impact on the molecular sieve in the adsorption tower can be slowed down, so as to prolong the service life of the carbon molecular sieve. The switching speed of the reference valve gate is generally selected as the pressure equalization time of 1 to 3 seconds.

4). Gas production time

According to the different adsorption and diffusion rates of carbon molecular sieve for oxygen and nitrogen, its adsorption of O2 reaches equilibrium in a short time. At this time, the adsorption amount of N2 is very small, and a short gas production time can effectively improve the gas production of carbon molecular sieve. At the same time, it also increases the operating frequency of the valve, so the performance of the valve is also very important. Generally, the adsorption time is selected to be 2X50S (can be adjustable). Short gas production time is recommended for small high-purity nitrogen generators, and long gas production time is recommended for large low-concentration machines.

5). Operating pressure

Carbon molecular sieve not only has kinetic effect, but also has equilibrium adsorption effect, high partial pressure of adsorbate and high adsorption capacity, so pressurized adsorption is advantageous, but the adsorption pressure is too high, and the selection requirements for air compressors are also increased. In addition, the two processes of atmospheric regeneration and vacuum regeneration have different requirements for adsorption pressure. Considering various factors, it is recommended that the adsorption pressure of the atmospheric regeneration process should be selected as 5-8Kg/cm2; the adsorption pressure of the vacuum regeneration process should be selected as 3 ~5Kg/cm2 is appropriate.

6). Operating temperature

Selecting a lower adsorption temperature as an adsorbent is conducive to the performance of carbon molecular sieves, and it is best to reduce the adsorption temperature in the nitrogen generator process under conditions.

4. The application example of carbon molecular sieve

|

Application |

Features |

|

Removal of odor from beer and wine |

Removal of sunlight odor, peculiar odor, regeneration of aged wine, etc. |

|

Fruit preservation |

Removes ripening hormones (such as ethylene) and maintains aromatic components |

|

Separation of rare gases in atomic power reactors |

Adsorption hernia |

|

Cigarette filter |

Removes tar and other residues such as menthol |

|

Separation of Oxygen and Nitrogen |

Adsorption of Oxygen by Difference in adsorption rate |

|

Tire flushed with nitrogen |

Improve the life of tires. |