99% alumina ceramic ball

2021-08-30

99% alumina ceramic balls, also known as alumina filler balls, mainly use α-Al2O3 industrial alumina powder, which is finished product after batching, wet grinding, forming, sintering, and quality inspection. As the content of ultrafine α-Al2O3 industrial alumina powder increases , that means the higher the alumina oxide is, the compressive strength and hardness are also higher. The 99% high alumina ball produced by Jiangxi OIM Chemical has a temperature resistance of 1800°C, an acid-base resistance greater than 96%, and is resistant to oxidation, and does not drop powder at high temperatures. Its compressive strength is above 235kg/cm3, and its hardness is above 9 grade.

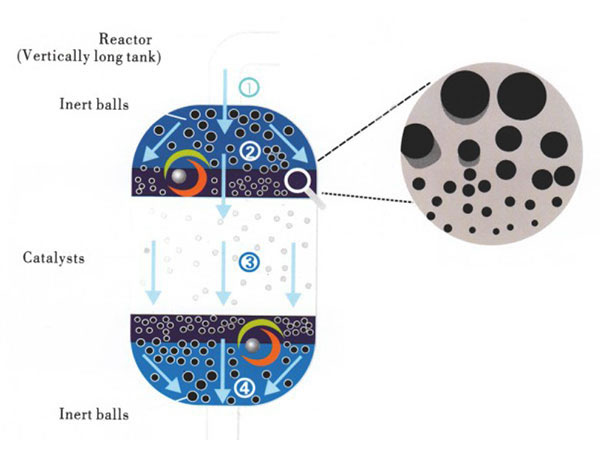

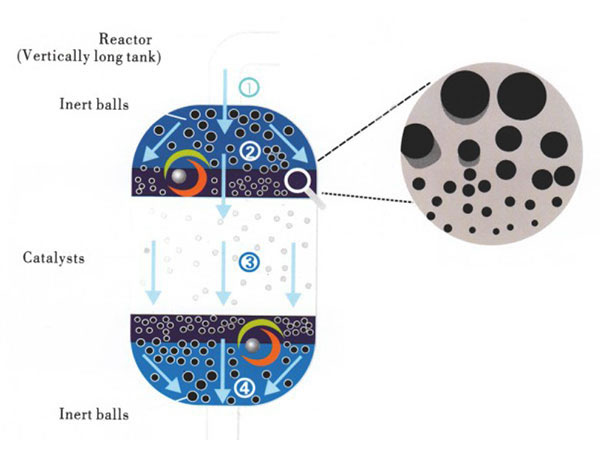

Alumina ceramic balls have good thermal shock stability and stable chemical properties. They are widely used in petrochemical plants, chemical fiber plants, alkylbenzene plants, aromatic plants, ethylene plants, natural gas plants and other hydrocracking units, refining units, and catalytic reforming units. Bottom packing materials such as isomerization device, demethylation device, etc., can also be used as support media materials and tower packing for catalysts, molecular sieves, desiccants etc. in the reactor. The main function is to increase the gas or liquid distribution points, support and protect the active catalyst with low strength.

Our company also produces adsorbents such as molecular sieve, activated alumina, silica gel, etc., which are widely used in petroleum and petrochemical industries. Welcome customers to visit and guidance.