Adsorbents for air adsorption dryer

2022-04-15

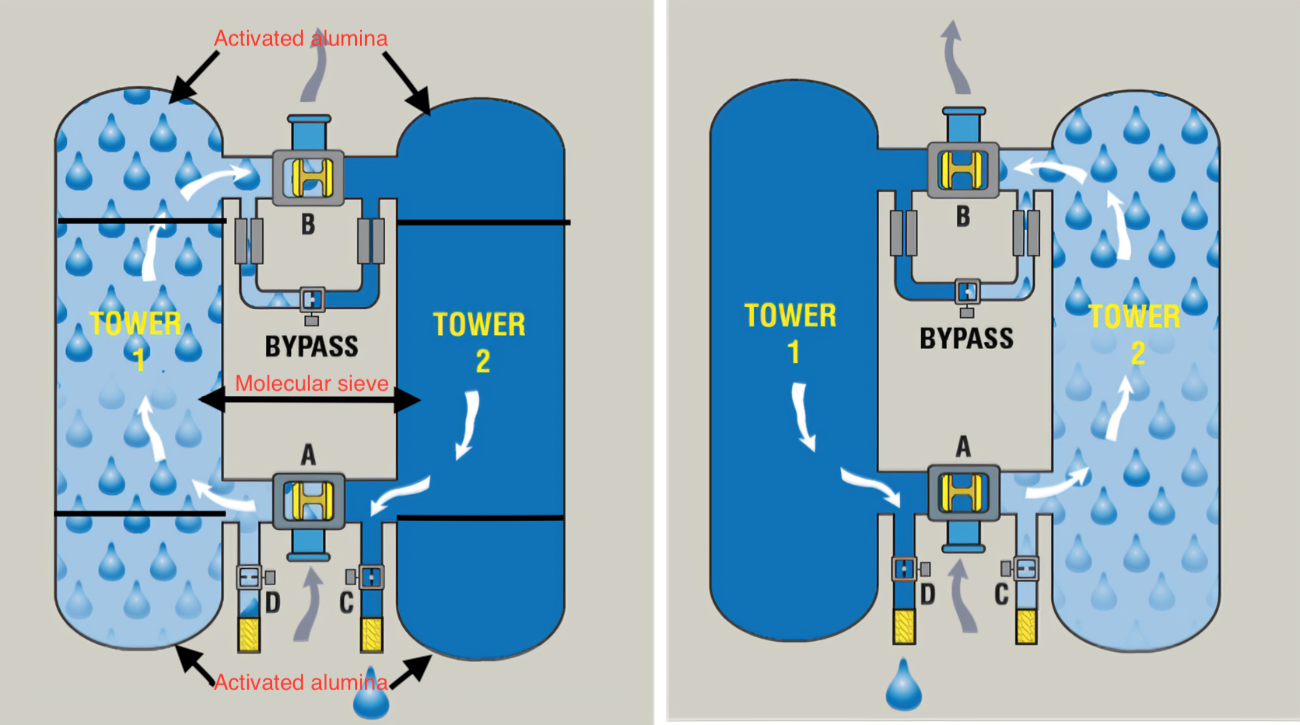

The principle of the adsorption dryer is to use the saturated compressed air to take advantage of the difference in the volume of moisture and air molecules. The molecular sieve for gas purification is used to filter and remove the saturated water vapor in the compressed air, which can easily adsorb the water molecules in the molecular sieve particles. , and then use the regeneration method to reduce the molecular sieve, the dew point of the compressed air can easily reach -40 ℃.

1. Classification of adsorption dryers

Generally divided into 4 types: Heatless regeneration air dryer; Heated regeneration adsorption air dryer; compression heat adsorption air dryer; blower heated adsorption air dryer.

Heatless regeneration air dryer: If the dew point requirement is not high, activated alumina can be recommended, and molecular sieve 4A is not recommended. And the general intake temperature of this regeneration is 38 degrees, pressure 0.7Mpa. If the temperature is too high or the pressure is too low, the energy consumption of regeneration will be too high. Generally, the air consumption of regeneration is 15-20%.

1) Compressed air: Such as high moisture load, the strength of the adsorbent is not high, and long-term operation will cause high bulk density and increase air pressure drop. Only use molecular sieve 4A if the dew point is lower than -40 degrees;

2) If the moisture content of the intake air is large, need pre-treat it with activated alumina and silica gel, and then use molecular sieve 4A to absorb the remaining moisture. If molecular sieve is used as an adsorbent regardless of the occasion, the harms often outweigh the benefits.

2. Regeneration of adsorbents

1). Adsorbent regeneration temperature: Usually the temperature of activated alumina is 160-190 degrees; molecular sieve 200-250 degrees and silica alumina gel is 120-150 degrees.

Under low moisture loading, molecular sieve is better for adsorption; and under high moisture loading, activated alumina and silica gel are more suitable as adsorbents.

2).Classification of regeneration methods: Usually there are three kinds of methods: Heating regeneration; Depressurization regeneration; Vacuum analysis regeneration. If the long-term regeneration is not complete, for example, the regeneration temperature is not enough, or the regeneration time is not enough, the strength of the adsorbent is likely to decrease, resulting in pulverization of the adsorbent.

3. Filling of the adsorbents in the adsorption dryer

1). If Single activated alumina ball fails to meet the dew point requirements, it will be mixed and filled according to the proportioning method of the adsorbents. The order of loading is generally determined according to the crush strength: the crush strength of activated alumina is often greater than that of molecular sieve and silica gel.

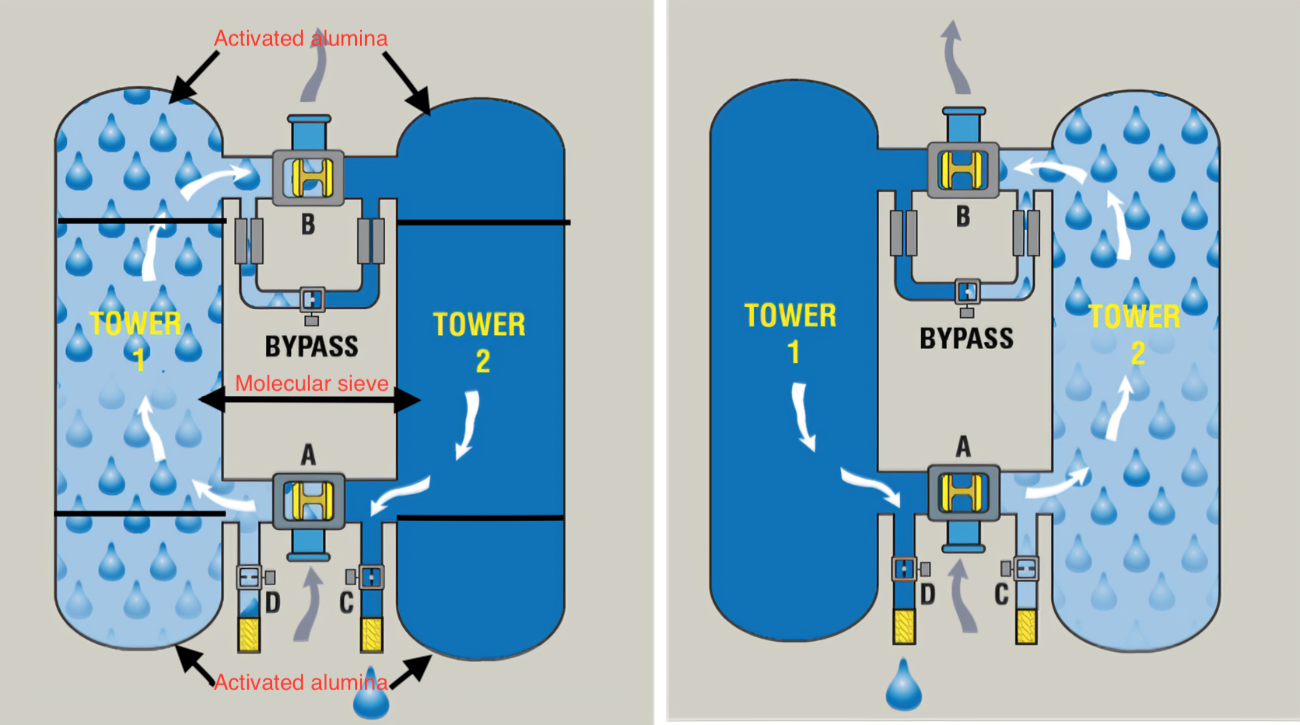

2). Under the loading conditions of strong airflow and high air pressure, we recommend loading activated alumina with high compressive strength. This can prevent the adsorbent from being pulverized and broken under the impact of strong airflow. The order is generally to use strong activated alumina at the bottom and top of the suction dryer, and mix and fill with molecular sieve in the middle.

3). If the requirements for dew point are higher, different adsorbents are generally selected for the ratio, which can be mixed and matched with activated alumina, silica-alumina and molecular sieve.