Working principle of oxygen molecular sieves in VPSA Oxygen Generators

2023-09-26

Oxygen molecular sieves are critical components in these generators, which are commonly used to produce high-purity oxygen. Let me help you explain their working principle.

VPSA Oxygen Generators are designed to separate oxygen from air by utilizing the principle of adsorption. They are widely used in industries such as healthcare, water treatment, and metal fabrication, where a reliable source of oxygen is essential.

Within VPSA Oxygen Generators, oxygen molecular sieves are responsible for the separation process. These sieves are specialized adsorbent materials consisting of zeolite crystals. Zeolite is a porous substance with a unique structure that allows it to selectively adsorb certain molecules while excluding others.

Now, let's explore the working principle in detail. The process starts with the intake of ambient air, which is a mixture of various gases, including nitrogen, oxygen, carbon dioxide, and traces of other components.

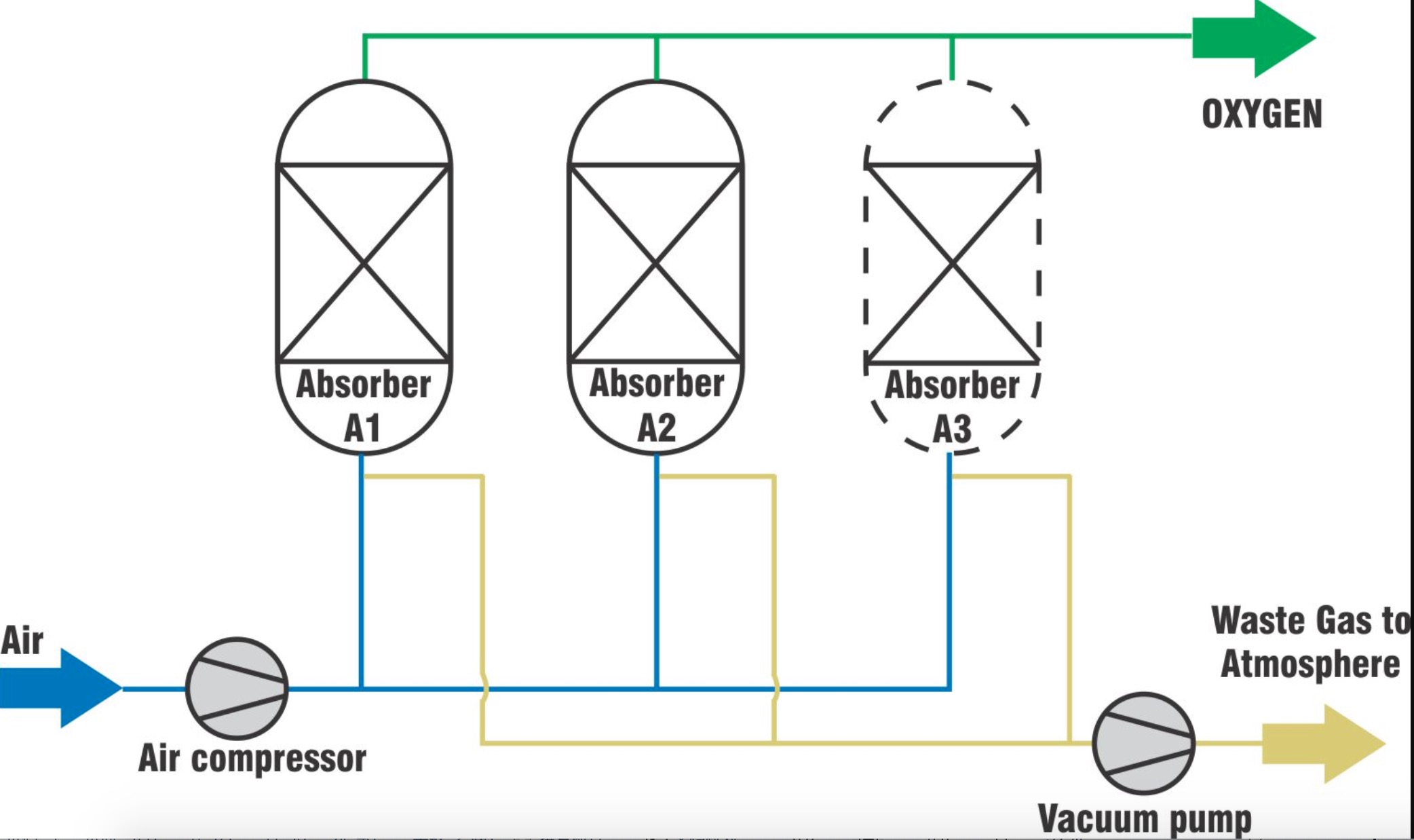

Inside the oxygen generator, the air is first compressed and then fed into a vessel containing the oxygen molecular sieves. These molecular sieves act as adsorbents that have a strong affinity for nitrogen molecules, favoring their adsorption and retention.

As the compressed air enters the vessel, the oxygen molecules pass through the zeolite pores more readily than nitrogen molecules due to their smaller size. This preferential permeation of oxygen across the zeolite structure results in the concentration of oxygen in the product stream.

Meanwhile, the nitrogen molecules are efficiently adsorbed by the zeolite crystals, causing them to be temporarily retained in the vessel. This selective adsorption process allows for the separation of oxygen from the original air mixture.

To maintain a continuous supply of oxygen, the VPSA Oxygen Generator operates in a cyclical manner. It requires two distinct phases: Adsorption and Desorption.

During the adsorption phase, air flows through the vessel, and the zeolite sieves selectively adsorb nitrogen molecules, while oxygen molecules pass through. The nitrogen-rich stream remains trapped in the vessel, whereas the purified oxygen gets collected and directed into storage for application or further processing.

Once the zeolite sieves near their adsorption capacity, the desorption phase begins. At this stage, the vessel pressure is reduced, effectively creating a vacuum. This reduction in pressure causes the trapped nitrogen molecules within the zeolite structure to desorb and release from the adsorbent material.

The released nitrogen is then vented out of the system, and the zeolite sieves are ready for a new adsorption cycle. This cyclic process of alternating between adsorption and desorption leads to the sustained production of high-purity oxygen.

The working principle of oxygen molecular sieves in VPSA Oxygen Generators enables the generation of oxygen with a purity level suitable for various applications. These generators provide a cost-effective and reliable solution for industries that require a continuous supply of oxygen.