Precautions for producing nitrogen from carbon molecular sieve

2023-03-28

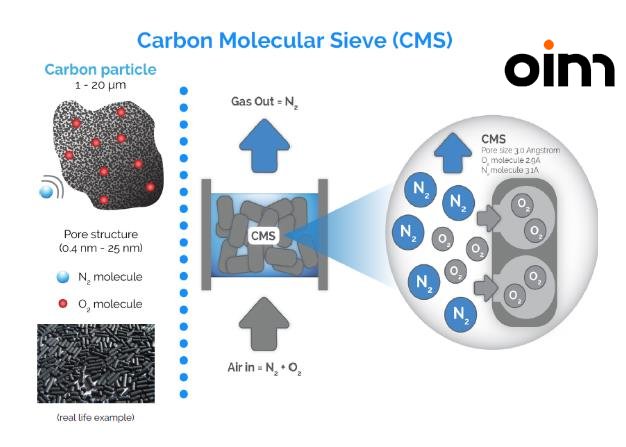

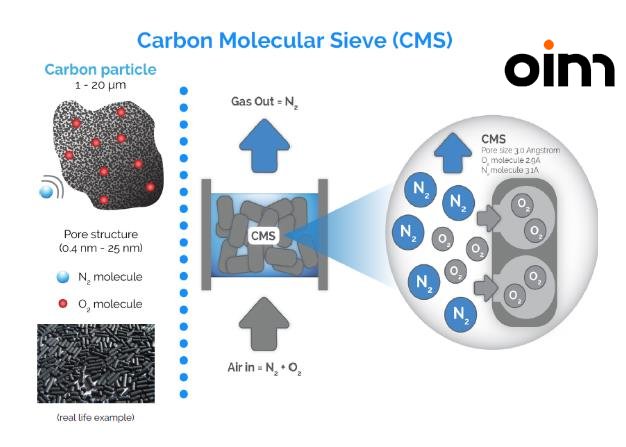

Carbon molecular sieve is a new type of adsorbent. It is also an excellent non-polar carbon material. Carbon molecular sieves for nitrogen production are used to separate and enrich nitrogen from air, using a nitrogen production process at room temperature and low pressure. It is the preferred pressure swing adsorption air separation nitrogen rich adsorbent in industry.

Carbon molecular sieve produced by most manufacturers do not differ much in appearance, but if their price is significantly lower than the market value, we should pay attention. They may be reusing recycled materials; Or perhaps his raw materials are not entirely new, mixed in half. The carbon molecular sieve produced by Jiangxi OIM Chemical can be compared and distinguished in terms of raw materials. The service life is at least 3-5 years, and the nitrogen production effect is good, reaching at least 99.999% nitrogen purity.

So what are the conditions that need to be met for carbon molecular sieve to produce nitrogen in order for our carbon molecular sieve to achieve the optimal nitrogen production effect?

1. Air compression purification process

It is necessary for pure raw material air to enter the carbon molecular sieve adsorption tower, as particles and organic atmosphere entering the adsorption tower will block the micropores of the carbon molecular sieve and gradually reduce its separation performance.

The methods for purifying raw air include: 1). keeping the air inlet of the air compressor away from places with dust, oil mist, and organic atmosphere; 2). Through a cold dryer, adsorbent purification system, etc., the final treated raw air enters the carbon molecular sieve adsorption tower.

2. Concentration and gas production of nitrogen gas in the product

Carbon molecular sieve can be used to produce nitrogen, and its N2 concentration and gas production can be adjusted according to user needs. When the gas production time and operating pressure are determined, lowering the gas production will increase the N2 concentration, and vice versa, the N2 concentration will decrease. Users can adjust according to actual needs.

3. Equalization time

The nitrogen production process of carbon molecular sieve involves injecting pressurized gas from one adsorption tower into another regenerated adsorption tower from both directions when the adsorption is completed. This process is called pressure equalization of the adsorption tower. By selecting an appropriate pressure equalization time, energy can be recovered and the impact on the molecular sieve in the adsorption tower can be reduced, thereby extending the service life of the carbon molecular sieve. The switching speed of the reference gate is generally selected with a voltage equalization time of 1-3 seconds.

4. Gas production time

According to the different adsorption and diffusion rates of oxygen and nitrogen on carbon molecular sieves, their adsorption of O2 reaches equilibrium in a short period of time. At this time, the adsorption amount of N2 is very small, and a shorter gas production time can effectively improve the gas production rate of carbon molecular sieves. However, it also increases the frequency of valve action, so the performance of valve is also important. Generally, the adsorption time is chosen to be 30-120 seconds. Short gas production time is recommended for small high-purity nitrogen generators, while long gas production time is recommended for large low concentrations.

5. Operating pressure

Carbon molecular sieves not only have dynamic effects, but also have equilibrium adsorption effects. The adsorbate partial pressure is high, and the adsorption capacity is also high. Therefore, pressurized adsorption is advantageous. However, if the adsorption pressure is too high, the selection requirements for air compressors also increase. In addition, the adsorption pressure requirements for atmospheric regeneration and vacuum regeneration processes are different. Taking into account various factors, it is recommended to choose the adsorption pressure of 5-8Kg/cm2 for the atmospheric regeneration process; The optimal adsorption pressure for the vacuum regeneration process is 3-5 Kg/cm2.

6. Operating temperature

Choosing a lower adsorption temperature as an adsorbent is beneficial for the performance of carbon molecular sieves, and reducing the adsorption temperature is beneficial for nitrogen making machine processes when conditions permit.

In the first quarter of 2023, we exported many tons of carbon molecular sieve CMS260 by sea. Welcome domestic and foreign customers to visit our factory at any time. More details, contact info@oimchem.com,