Technical article

2023-04-21

Molecular sieve 4a adsorbent is mainly used for air separation equipment, natural gas dehydration, cyclic purification of alkanes, refrigerants, and various electronic component drying. Its instant adsorption capacity is strong, water absorption rate is high, and its selective absorption of water is higher than any other molecule. Moreover, molecular sieve 4a can also adsorb methanol, ethanol, hydrogen sulfide, sulfur dioxide, carbon dioxide, etc. Widely used for deep purification of drinking water, industrial water, and wastewater; Separation and purification of various gases, nitrogen and oxygen purification, purification; Organic solvent recovery; Decolorization, deodorization, and refining of sugar, monosodium glutamate, medicine, alcohol, and beverages; Precious metal extraction; Catalysts and catalyst carriers in the chemical industry.

It uses excellent porous zeolite powder and resin as raw materials, and is refined using a reliable process. The appearance is earth yellow spherical particles. Odorless, odorless, insoluble in water or methanol ethanol in general solutions. Molecular sieve 4a has the characteristics of large specific area, strong adsorption capacity, high purity, fast filtration rate, and stable quality.

So how to deal with the water absorption and dampness of 4a molecular sieve when its packaging is not tight or the storage environment is damaged? Now we will introduce the adsorption capacity and water absorption of molecular sieves, as well as regeneration methods.

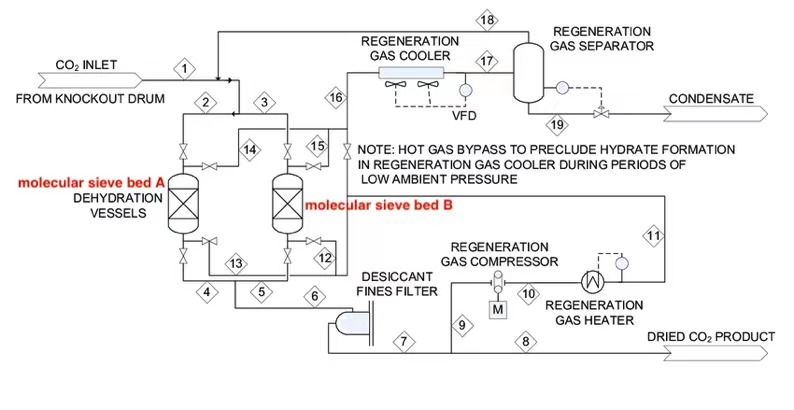

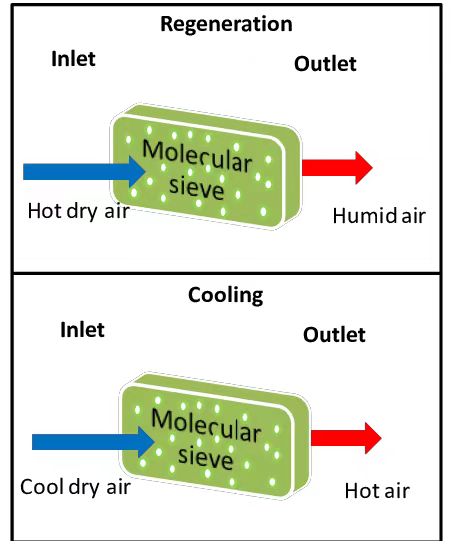

1、Close the main inlet valve of the tower, simply switch the adsorption of the molecular sieves in the two tanks, and use the air after the non inlet molecular sieve to regenerate the inlet molecular sieve. However, when the inlet molecular sieve is converted to operation, the moisture behind it enters the non inlet molecular sieve. Both types of molecular sieves contain water, which is then regenerated from each other. With adsorption regeneration, the water content decreases and ultimately reaches simultaneous adsorption.

2、Directly heat and dry the molecular sieve 4a to dehydrate it as soon as possible and restore its adsorption capacity; But after a large amount of water enters the molecular sieve, when the above method is used for regeneration, both molecular sieves generate a large amount of water, and both are regenerated, ultimately losing their adsorption capacity. The reason is: after a large amount of water is fed into the zeolite, the water reacts with the zeolite, and the water changes from free state to water of crystallization of the zeolite. Even if the regeneration temperature is 200 degrees, water of crystallization cannot be removed, and the adsorption function of the zeolite can be restored only after it is returned to the furnace at 400 degrees by the manufacturer!