Technical article

2024-01-25

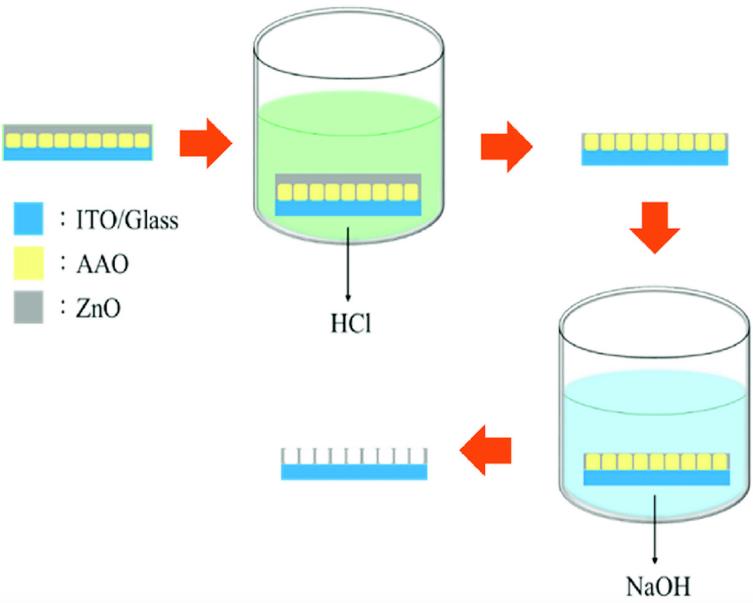

Activated alumina, a highly porous and adsorbent material, plays a crucial role in various industrial processes, especially in handling corrosive substances like hydrochloric acid (HCl). Understanding how activated alumina works in the presence of HCl is essential for optimizing processes and ensuring safety. Let's delve into the realm of activated alumina and its interactions with HCl.

In industrial processes, the presence of hydrochloric acid (HCl) can pose challenges in water treatment due to its corrosive nature and potential harm to equipment and the environment. Activated alumina, a highly porous and versatile material, plays a crucial role in effectively removing HCl from water streams.

Activated alumina is known for its high surface area and adsorption capacity. When used in water treatment for HCl removal, activated alumina works by adsorbing the HCl molecules onto its surface. The porous structure of activated alumina provides a large surface area for HCl molecules to bind to, thereby effectively reducing the concentration of HCl in the water.

In water treatment applications, activated alumina is typically packed in columns or filters through which the HCl-contaminated water flows. As the water passes through the activated alumina bed, the HCl molecules are adsorbed onto the surface of the alumina particles, resulting in purified water that is significantly.