Applications of 316L Metal Pall Rings

2024-04-17

Recently, many customers inquired about metal pall rings. Meanwhile, the 316L stainless steel pall ring is generally the most inquired about. So today, we will take you to a better understanding of 316L metal pall ring.

Firstly, we need to start with the material 316L stainless steel. In simple terms, we can say it is an austenitic stainless steel with better corrosion resistance and good mechanical properties than SS304. Has the following characteristics:

1. Chemical composition (%)

|

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Mo |

|

≤0.030 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.045 |

16~18 |

10~14 |

2~3 |

It is based on National Standard. So before purchasing the 316L metal pall ring, the manufacturer needs to provide a formal report on the 316L stainless steel strip to avoid purchasing materials with other properties. And 316L has an extremely low level of carbon (maximum 0.03%), which allows 316L to maintain good corrosion resistance without annealing after welding.

2. Corrosion resistance

The common types in the market are 304 stainless steel and 316L stainless steel, but in terms of corrosion resistance, 316L has better corrosion performance than 304 stainless steel. It has good corrosion resistance and pitting resistance to various organic and inorganic acids, especially for applications with high requirements for corrosion resistance, such as chemical and marine equipment industries, which have higher requirements.

3. Mechanical performance

|

Yield Point |

Tensile Strength Resistance |

Elongation |

|

≥170 |

≥485 |

≥40 |

|

Hardness: ≤220 |

It is based on National Standard, and relevant testing needs to be carried out after annealing. If it meets the above standards, it indicates that the finished metal ball ring processed will not deform in practical application environments. And the 316L stainless steel pall ring has good strength and oxidation resistance at high temperatures, as well as good heat resistance.

4. Testing standards

316L is a stainless steel material grade, which corresponds to the American Standard AISI 316L.

So what is the purpose of the 316L stainless steel metal pall ring processed into a finished product?

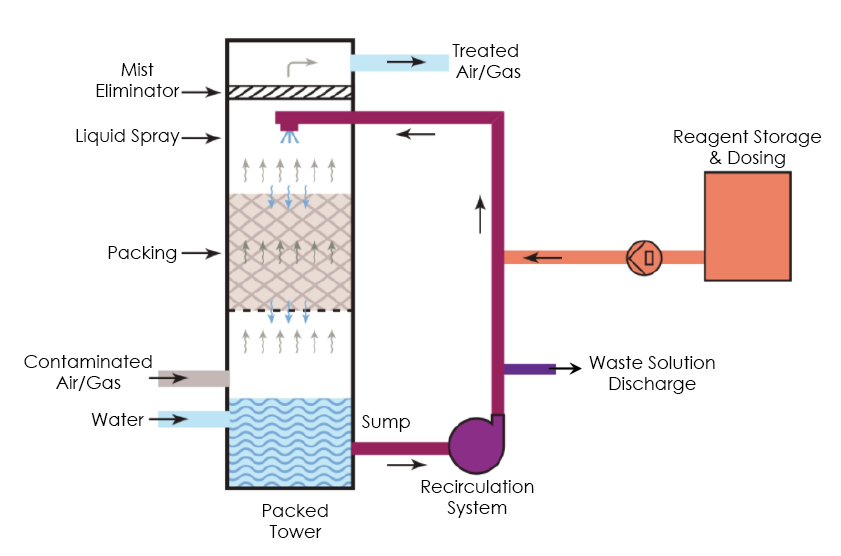

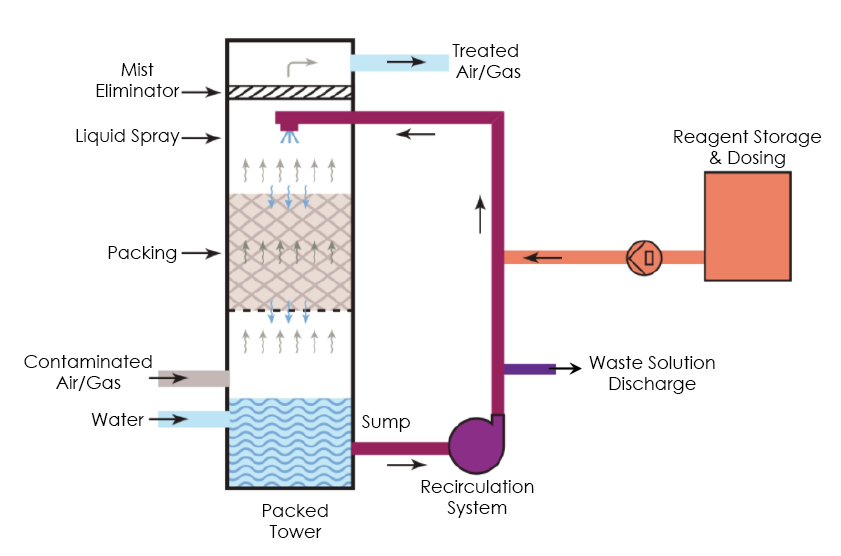

We need know that stainless steel pall rings are suitable for various separation, absorption, ammonia decarbonization, desulfurization systems, ethylbenzene separation, desorption devices, etc. Used for the above devices, it can effectively improve the dimensional stability, surface smoothness, smoothness, etc. of the finished product. At the same time, it can meet different performance requirements and act as a mass transfer agent in the packed tower, improving the efficiency of liquid transfer.

The above is a brief introduction to stainless steel material 316L and finished 316L pall rings. At the same time, we also have various metal rings of different materials and sizes. Welcome new and regular customers to consult with us.