Technical article

2023-09-07

Stainless steel 316L pall rings are widely used in various industries due to their unique properties and applications. Let's dive into the details!

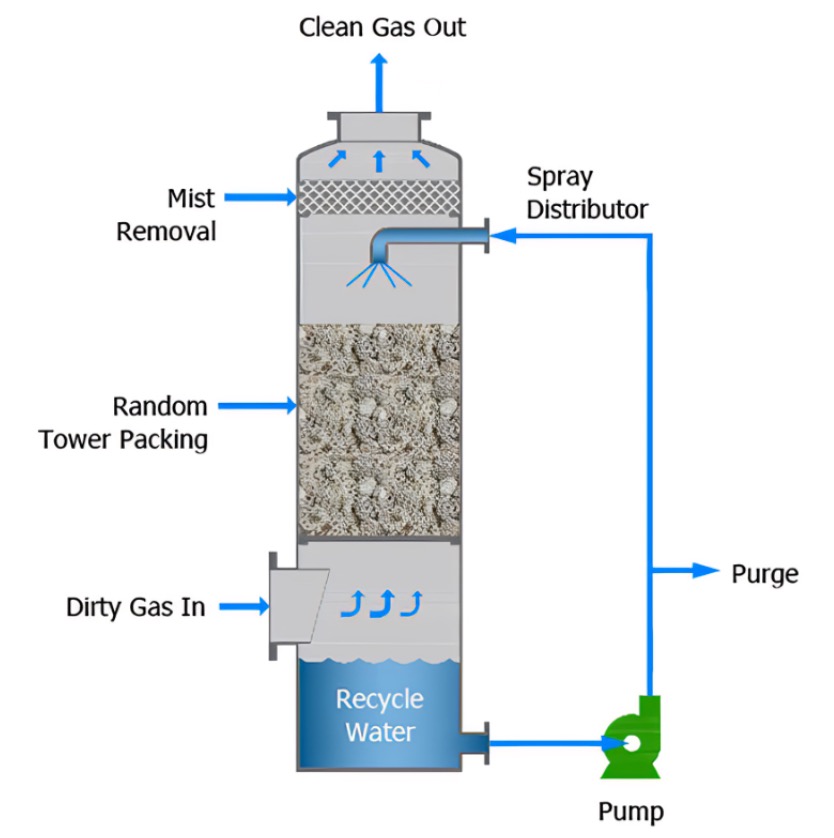

Stainless steel 316L pall rings are a type of tower packing material used in gas and liquid separation processes, typically found in distillation, absorption, and stripping columns. These rings have a distinctive design with inward and outward protrusions, allowing for increased surface area and improved performance compared to traditional random packing.

One of the key advantages of stainless steel 316L pall rings is their exceptional corrosion resistance. The addition of molybdenum to the stainless steel alloy provides enhanced resistance to corrosive media, such as acids, alkalis, and chlorides. This makes them suitable for applications in chemical processing plants, petrochemical industries, and wastewater treatment facilities.

Furthermore, the unique geometric shape of pall rings promotes effective liquid distribution and prevents channeling and nesting issues. The inner and outer protrusions create a large number of contact points between the liquid and gas phases, ensuring efficient mass transfer and improved separation performance.

Stainless steel 316L pall rings are also known for their high mechanical strength and thermal stability. They can withstand high temperatures without deformation or degradation, making them ideal for processes that involve elevated operating conditions.

In terms of application, stainless steel 316L pall rings are commonly used in processes such as:

Distillation tower: They facilitate the separation of liquid mixtures by vaporizing the components with different boiling points.

Absorption tower: Pall rings can be utilized to transfer a gas component into a liquid phase for purification or recovery purposes.