RFQ: Air Compressed Dryer Activated Alumina

2023-06-05

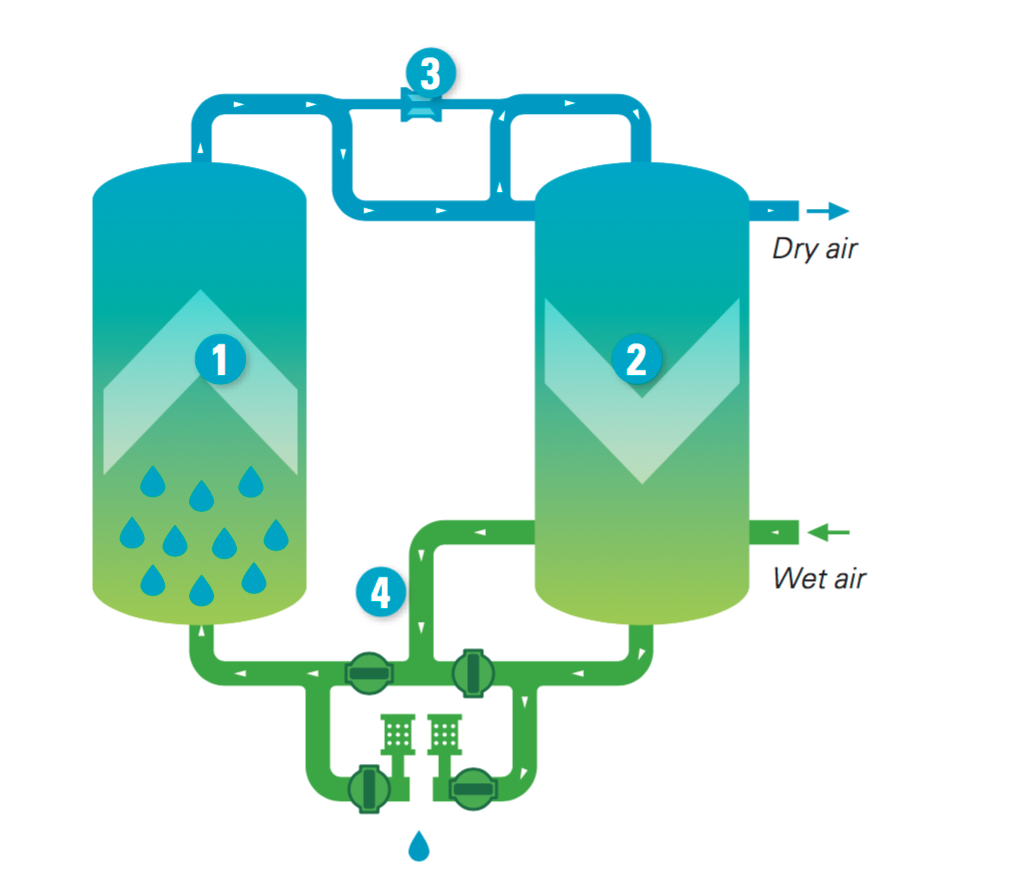

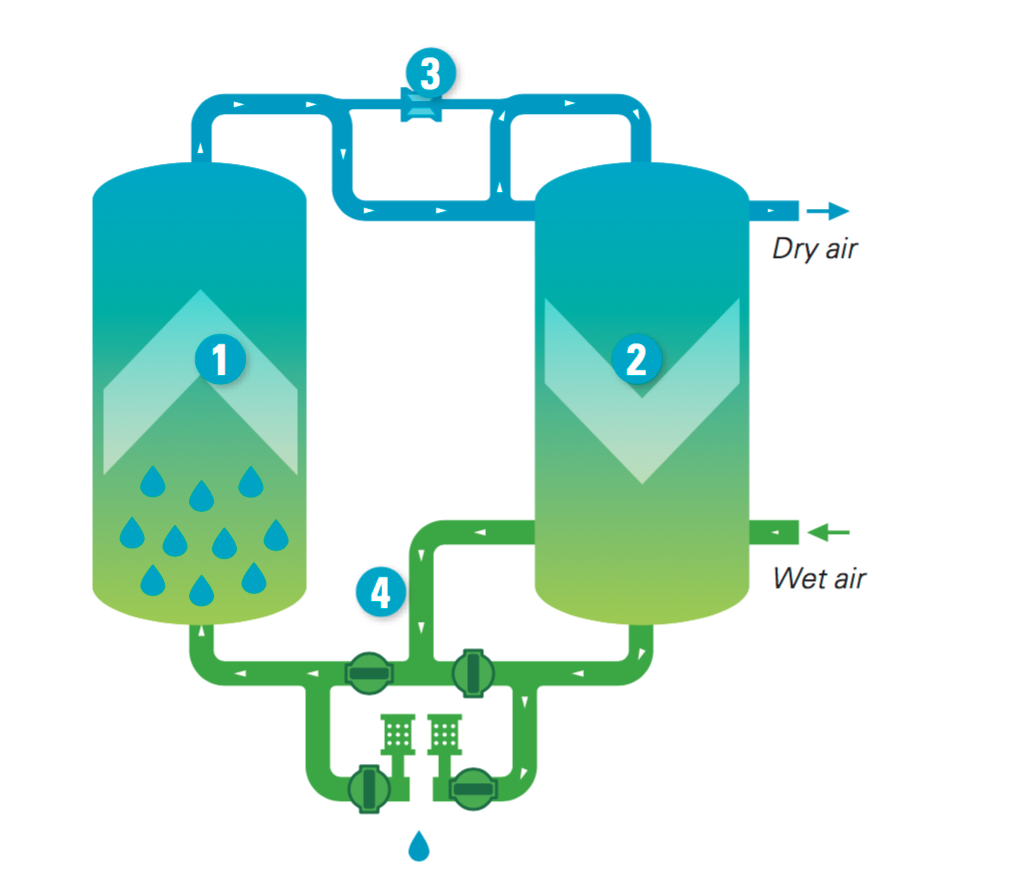

The heatless regeneration adsorption dryer is an advanced device that uses the pressure swing adsorption principle to dry compressed air by filling activated alumina or molecular sieve with high water absorption. It is usually possible to dry compressed air to a dew point of -40 to -70 degrees Celsius.

Many customers have doubts about replacing the adsorbent in the vacuum dryer and do not know which adsorbent to choose. The following are some common questions we have compiled about using adsorbents in compressed dryers.

1. What is the regeneration temperature of molecular sieve, activated alumina, water resistance silica alumina gel?

Activated alumina: 160 ℃ - 190 ℃

Molecular sieve: 200 ℃ -250 ℃

Water resistance silica alumina gel: 120 ℃ -150 ℃

Under normal operating conditions, only filling with water resistance silica alumina gel can achieve a pressure dew point of -60 ℃

2. Besides product quality, what are the reasons for the broken balls in the compressed dryer?

* Adsorbent water ingress reduces compressive strength and leads to loose filling.

* There is no equalizing system or the equalizing system is blocked, resulting in excessive impact force.

* The use of stirring rods for filling affects the compressive strength of the product.

3. What is the dew point of all activated alumina used in the dryer?

Dew point -70 ℃ (atmospheric dew point)

Dew point -40 ℃ to -45 ℃ (pressure dew point)

4. What product can achieve a pressure dew point of -70 degrees?

All 13X molecular sieves or 13X molecular sieves plus activated alumina (our activated alumina mainly plays the role of protecting molecular sieves and pre dehydration)

5. Dew point is required to be - 70 ℃. How to distribute molecular sieve, activated alumina and silica alumina gel?

The bottom air intake part is filled with activated alumina, the middle layer is paved with water resistance silica alumina gel, and the top layer is filled with molecular sieve.

6. What is the reason for the rapid decrease in dew point after using the product in the compressed dryer for a period of time?

In Tower A and Tower B of the suction dryer, the regeneration of the adsorbent is not thorough enough.

7. What is the size of activated alumina commonly used in the dryer?

Usually 3-5mm, 4-6mm, 5-7mm is often size.

The above are some of the problems we have sorted out about activated alumina used in the dryer. If you have any further questions, welcome new and regular customers to contact us by phone or email.