Over 10 days for customized product.

It is called pure alumina ball. Equaled Denstone®99 Support Media. It is in chemical composition99+% alpha alumina and a maximum 0.2wt% SiO2. Because of its high alumina content and low silica(SiO2), it's a very excellent and ideal product for high temperature and steam applications. It has a high purity, excellent thermal propertoes.high temperature, high pressure resistance. And low water adsorption.

| Type | Inert Alumina Ball-99 | ||||||||||||

| Color | White | ||||||||||||

| Shape | Ball | ||||||||||||

| Chemical composition | Min. % | Max. % | Usual % | ||||||||||

| Al2O3 | 99 | 99.6 | 99.3 | ||||||||||

| SiO2 | / | 0.2 | 0.18 | ||||||||||

| Fe2O3 | / | 0.2 | 0.02 | ||||||||||

| TiO2 | / | 0.55 | 0.02 | ||||||||||

| CaO | / | 0.1 | 0.02 | ||||||||||

| MgO | / | 0.1 | 0.05 | ||||||||||

| Na2O | / | 0.25 | 0.1 | ||||||||||

| K2O | / | 0.2 | 0.13 | ||||||||||

| Physical properties | Leachable Iron (%) | ≤0.01 | |||||||||||

| Apparent Porosity by Weight (%) | ≤7.0 | ||||||||||||

| H2O absorption (wt.%) | <4.0 | ||||||||||||

| Acid resistance (%) | >99.8 | ||||||||||||

| Alkaline resistance (%) | ≥90 | ||||||||||||

| Bulk Density | (g/cm3) | 2.1 | |||||||||||

| (lb/ft3) | 131 | ||||||||||||

| Specific density | (kg/m3) | 3400 | |||||||||||

| (lb/ft3) | 212 | ||||||||||||

| Moh’s hardness (scale) | >8.0 | ||||||||||||

| Thermal conductivity (w/m2.k) | 0.7-0.8 | ||||||||||||

| Max. Operating Temperature | (℃) | 1550 | |||||||||||

| (℉) | 2822 | ||||||||||||

|

Thermal expansion (%) (500℃) |

0.10 | ||||||||||||

|

Thermal Shock Stability (times) (1000℃ then water cooling) |

10 | ||||||||||||

| Geometric properties | Nominal Size | (mm) | 3 | 6 | 10 | 13 | 16 | 19 | 25 | 38 | 50 | ||

| (inch) | 1/8 | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1.5 | 2 | ||||

| Crush Strength Min. | (lbs) | 115 | 230 | 440 | 1355 | 1720 | 3344 | 3432 | 4034 | 4960 | |||

| (kg) | 52 | 105 | 200 | 615 | 780 | 1520 | 1560 | 1830 | 2250 | ||||

| (N/PC) | 510 | 1030 | 1961 | 6031 | 7650 | 14896 | 15288 | 17946 | 22065 | ||||

1. High compressive strength;

2. Stability, acid and alkali resistance;

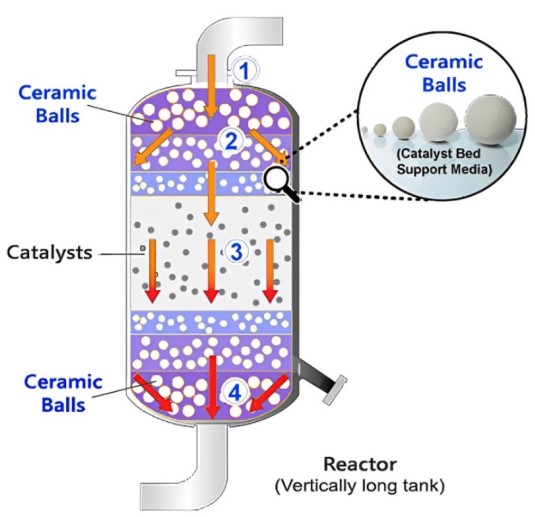

3. Support and protect active catalyst;

4. Sufficient stock of common types balls and timely delivery.